Properties and Applications of Engineering Thermoplastics

1. Polyethylene Terephthalate (PET)

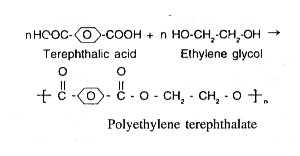

PET was discovered in 1941 by John Rox Dhirifield. It was commercialized in 1953. Engineering PET was introduced by Du pont in 1970's. In recent years, copolymers of PET have become increasingly important. PET is manufactured by condensation reaction between ethylene glycol (EG) with terephthalic acid (TPA) or dimethyl terephthalate (DMT). PET Polymerisation takes place in two stages. In the first stage, a prepolymer is formed by heating the reaction mixture and removing the volatile byproduct and excess glycol. In the second stage, heat and vacuum are employed to increase the molecular weight with concurrent removal of volatile products, such as water and glycol.

Characteristics

- Outstanding chemical resistance to organic and inorganic liquids.

- Water repellent

- Sterilizable by ethylene oxide and X-rays.

- Inherent good electrical property

- Ability to orient

- Good tensile strength

- Superior strength and stiffness

- Excellent dimensional stability

- Excellent melt strength with slower crystallization rate

- Good impact strength even at low temperature

- Excellent formability

- High tear strength

- Heat resistant

- Flame retardant

- Outstanding clarity

- High gloss

Applications

Appliances: Oven and appliance handles, coil forms for microwave oven transformers, small appliance structural frames, panels, chassis and housings and instrument covers

Automotive: Structural parts such as luggage racks and grills, functional housing such as windshield, wiper motor housings, fuel filters, blade supports and end bells, sensor, lamp sockets, relays, switches and solenoids.

Electrical/Electronics: Lamp sockets, coil forms for audio/video transformers, terminal blocks, electrical/electronic connectors and thrust washers.

Films: X-ray films, photographic films, magnetic tapes and printing sheets.

Furniture: Pedestal bases, seat pans, chair arms and casters.

Packaging: Carbonated soft drink containers, distilled spirits, toiletries, food products, mustard, pickle foods, peanut butter, spices, edible oil, cocktail mixers and syrups.

Miscellaneous: General purpose pump housings, mirror housings, three dimensional circuit boards and structural components in office automation equipments, computer housing and structural components, containers, trays, blisters and drinking cups.

Temperature Sensitivity

In the characterization of mechanical properties the previous three chapters have concentrated on the response of the material at ambient temperature, 23°C. While most structures spend most of their life near such a temperature, it is necessary to consider the response of the material over a range of temperatures that includes low temperatures as well as high. Civilian aircraft materials usually have to perform their duty in the temperature range - 50 to +80°C. For high-speed military aircraft skin temperatures up to 170°C may be encountered. High temperatures are also a feature of materials used in engines. There may also be adventitious exposure to very high temperatures in fires, tolerance of which may literally be a question of life or death. At the other end of the temperature scale is the possible use of composites for cryogenic storage of materials, including fuels such as liquid hydrogen. It is therefore necessary to consider the mechanical performance of thermoplastic composites from -270°C to +250°C, which latter temperature is usually considered to be the maximum continuous service temperature for polyetheretherketone in the form of an unfilled resin.

For structural composite materials the glass transition temperature represents a useful cut off point. For practical purposes a maximum working temperature of Tg minus 30OC has been suggested for load bearing structures. For polyetheretherketone this suggests a design temperature limitation of about 100°C. However, because PEEK is a semi-crystalline resin it is capable of useful service well above that temperature range in lightly loaded applications. The mechanical properties of PEEK resin have been characterized over the temperature range -80°C to +240°C for twelve decades of time. Since it is the resin whose properties are most sensitive to temperature, that characterization provides a vital starting point to the understanding of composite behaviour.

During the last five years there have been a number of programmes designed to develop new composite materials based on thermoplastic matrix resins with higher glass transition temperature, Tg. Typical of such developments are the melt preimpregnated product forms based on specifically designed matrices of the 'Victrex' family. These have included the semi-crystalline system APC (HTX), Tg 205°C, and the amorphous material APC (HTA). Tg 2600C. While semi-crystalline systems such as HTX (high temperature crystalline) and ITX (intermediate temperature crystalline) behave in a similar way to PEEK and retain some useful properties above Tg, the amorphous systems, HTA and ITA, which have the advantage of significantly higher glass transition temperature, must not be used above that temperature. Despite the considerable activity in developing such new systems, composites based on PEEK remain the most extensively characterized materials - in the open literature at least.

In the comparison of properties over a wide temperature range it is not always convenient to measure tensile properties directly. There can be difficulties in testing the required long specimens at very low temperatures, and at high temperatures significant problems of gripping the ends of the specimen are encountered. Flexural testing is a more versatile, if less precise, method from which comparative stiffness and strength can be deduced and, in this chapter, data from such testing, as well as from tensile and compression tests, are included. Where both flexure and tensile testing have been used, there is good qualitative agreement as to the influence of temperature on stiffness, but there may be quantitative differences in respect of strength measurements. Because flexure covers both shear and compression as well as extension, the flexural strength of axially aligned composites tends to be lower than the tensile strength, but transverse flexural strength is higher than transverse tension. For detailed results the reader is invited to refer to the publications cited, but, as a guide, the data in this chapter quote apparent properties relative to those at room temperature.

The Effect of Temperature on Stiffness

Table 1 collects typical reports of the stiffness of carbon fibre/PEEK composites relative to their stiffness at 23°C.

The only significant discrepancy in this table is the stiffness of the transverse specimens at high temperature. In his testing Leach used dynamic mechanical analysis and so had a short time scale for his tests. Hartness used tensile tests, and the stiffness may be presumed to be measured at much longer times. The results of Hartness are also based on 52% volume fraction, whereas Leach used 61%, so that matrix effects should be more significant. The difference between the results is consistent with creep mechanisms which are known to be significant near the Tg of PEEK. In respect of such creep behaviour, it is important to recognize that Ha reports that this response can be adequately predicted by a knowledge of the matrix behaviour, which has been thoroughly characterized by Jones.

Whereas creep is a problem for matrix dominated laminates at high temperature, the time dependent response of fibre dominated lay ups is the same at 120°C as it is at 23°C. Since good composite structure design would naturally arrange to have fibres oriented along the load path, we may conclude that the stiffness of such, correctly designed, laminates will not be affected by temperature in the range -268°C to +80°C. At 120°C there is likely to be a 5% reduction in composite stiffness as the matrix softens. At 180°C, 45°C above the glass transition temperature of the matrix,the stiffness of the composite is reduced by 10-15% and at 240°C, more than 100°C above Tg, the composite still retains 75% of its stiffness at room temperature.

2. The Influence of Temperature on Strength

Strength is a more complicated factor: it is necessary to consider^ compression as well as extension. There are also data available on the apparent short beam shear strength, a matrix dominated property. Typical results are collated in Table 2.

The results of Hartness are for composite based on 52% by volume of carbon fibre, and all other results are for 61% by volume carbon fibre: this difference may explain the fractionally lower results which he records. The resin sensitive properties -90° tension, short beam shear, ±45° tension, and uniaxial compression - fall off more rapidly than the fibre dominated properties, especially above the glass transition temperature. There is no significant loss of strength at very low temperature. Indeed there is evidence that the fibre dominated strength properties are significantly enhanced at temperatures close to absolute zero. As a first approximation we can say that, in the temperature range -268 to 120°C, the strength of carbon fibre reinforced PEEK composites based on 61% by volume of high strength carbon fibre is always at least 70% of the value measured at 23°C. At 180°C, 45°C above the glass transition temperature, this composite retains more than 40% of the strength properties that it has at room temperature.

The Applications of Thermoplastic Structural Composites

Structural materials, to which people must trust their lives, have to undergo a rigorous evaluation before they are put into service. Nowhere is this more true than in the aerospace sector, where the induction time for a new material to be extensively used is at least five, and typically ten, years. In the case of thermoplastic composite materials there is an added problem in respect of the development of appropriate manufacturing technology. The composite manufacturing industry has to make the transition from labour intensive hand lay up and protracted autoclave processes in order to exploit the high rate production potential of these new materials. In the evaluation stage, thermoplastic structural composites, and in particular preimpregnated carbon fibre reinforced polyetheretherketone, have demonstrated an excellent property profile, reproducibility, and durability: these designed materials are now beginning to take their place in serial production.

Carbon fibre/PEEK was designed as a material for aerospace. Innovative engineers have also demonstrated applications in the fields of prosthetic devices, marine technology, automotive engineering and specialized industrial machinery components.

1. Medical uses

One of the most successful operations in modern surgery is the replacement of hip joints. Bone is a living structure and, to be healthy, it needs stress in order to stimulate its growth and regeneration. Artificial hip joints made from stainless steel are stiff in comparison to bone, and this difference can cause the growth stimulating stresses to be reduced in the bone where the bone and prosthetic device join. The result of this loss of stimulus is a gradual deterioration of the bone and the possible need for remedial surgery. With composite materials there is the ability to tailor the anistropy of the fibres in such a manner that the stiffness of the prosthetic device can be designed to meet the needs of the bone1: the designer can tailor both the shape and the properties of his device. To be successful in such an application the material must at least be bio-inert, if not bio-compatible. Preliminary studies indicate that carbon fibre/PEEK meets these requirements. The toughness of this material is also of significance, since this allows it to be conveniently machined to shape without the danger of creating small fragments that might stimulate unwanted reaction from the body tissues.

Figure 1 shows a canine hip joint developed by Pfizer Howmedica. X-ray studies of the device one year after implantation have indicated a satisfactory condition of the surrounding bone.

As well as their use as implants, thermoplastic composite materials have potential as orthotic devices. De Lollis and Piancastelli note that high stiffness and strength per unit weight can enhance the confidence of the user. With thermoplastic composites there is also the potential for the structure to be conveniently tailored by post forming to meet individual requirements.

2. Satellites and Launch Vehicles

Nowhere are specific properties, stiffness, and strength divided by specific gravity, more highly prized than in space applications: Barnes notes that the cost of carrying a kilogram mass into orbit is of the order £5,000 to £10,000.

Launch vehicles themselves are heavy structures. Typical of the concepts for the next generation of such vehicles is the Horizontal Take Off and Landing vehicle HOTOL, described by Walmsley. The major structure is a fuel tank for liquid hydrogen, which must be capable of withstanding cryogenic shock without microcracking: and it appears that CF/PEEK is the only composite material which can do this. Evans confirms that the material does indeed have good resistance to permeation by hydrogen gas. In respect of fabrication such fuel tanks are cylindrical structures of very large size. Cylindrical structures are well suited to filament winding technology. Large filament windings are well suited to thermoplastic technology, because the infinite shelf life of the material means that the winding can be carried out over a long time, and because there is no requirement for large autoclaves in which to cure them. Walmsley considers carbon fibre reinforced PEEK as an appropriate material for such structures.

It is not just mass that contributes to launch costs. Volume is also a significant factor. Space station structures are inevitably bulky items. Spacecraft for deep space exploration are equally bulky and need not have the same structural characteristics as a vehicle designed to penetrate planetary atmospheres. Because thermoplastic composites can be shaped by heat and pressure, there is the potential to transfer the manufacturing process for bulky structures into space transporting there, in condensed form, only the materials and equipment necessary to carry out that task. On orbit fabrication should provide an important element of the next phase of mankind's exploration of space, and thermoplastic composites are well suited to play a role in that activity.

Earth launched satellite structures make extensive use of composite materials. Each year the United States Airforce TOPS (ThermOPlastics for Space) programme holds an annual workshop for companies working in this field. Typical of satellite structures being developed is an octagonal box structure, made from carbon fibre reinforced PEEK. That structure is remarkable for being built from prepregs based on both conventional high strength carbon fibre and ultra high modulus fibres; it also includes sub-components made from a hybridized staple fibre product form and conventional short fibre injection moulding. Such an approach to optimized structure design emphasizes the potential, optimally, to integrate the diversity of available thermoplastic systems.

In addition, Silverman and Jones note that carbon fibre reinforced PEEK composites have damping characteristics approximately three times as good as the current qualified grades of epoxy composites for this application. An important series of papers from the TRW Space and Technology Group, which includes an economic study demonstrating the advantages of thermoplastics, concludes that 'future spacecraft structural systems will be able to meet their projected flight requirements by using the superior performance and processing potential of thermoplastic materials over presently existing materials.

3. Aircraft Structures

Carbon fibre reinforced polyetheretherketone was first developed at a time of rapidly escalating fuel costs in order to enable commercial aircraft to operate more economically. The outstanding durability of structures made from such materials soon attracted military interest, and the United States Airforce has sponsored a series of annual workshops at which the progress of those materials to full scale application has been charted. Typical of the programmes that have been publicly disclosed is the development, by Lockheed, of a generic fighter forward fuselage structure and, by Westlands, of a tailplane for a helicopter. Extensive flight trials of demonstrator components have been in progress. Typical of such demonstrators is a carbon fibre/PEEK inspection panel on a Lynx helicopter that has been in service since 1983 and is showing no deterioration. The importance of inspection panels and hatches is that they are continually being removed from the aircraft so that ground technicians can maintain electronic and hydraulic systems. They are therefore subject to extensive handling and accidental damage. All reports from such trials have been uniformly encouraging.

One of the most significant demonstrator components has been the belly skin of a C-130 transport. During take-off and landing there is the possibility of runway debris being kicked up from the wheels, causing impact damage. The carbon fibre/PEEK belly skin of the C-130 is reported to have performed well during extended operation from 'unimproved' Alaskan runways, thereby confirming laboratory assessment of the toughness of the material under low temperature conditions. The underbody durability of carbon fibre/PEEK composites has also been verified by demonstration landing bay doors on military aircraft.

Because of the classified nature of military programmes, it is difficult to ascertain the extent to which thermoplastic composites are now being used. However, informed reflection indicates that, besides extensive demonstrator programmes, some aircraft primary structures made from thermoplastic composites have already entered production.

4. Marine applications

One of the longest serving demonstration components is on the leading edge of the rudder of a passenger carrying hovercraft. This component, installed by Westlands in 1983, has performed in exemplary fashion. As well as salt spray, normally a highly corrosive environment, there is the problem of impact resistance from sand and stones thrown up by the engines behind which the rudder is mounted. Those engines also provide a fatigue environment.

Besides the natural hazards of the ocean, fire and smoke are the most daunting enemies faced by those 'who go down to the sea in ships'. The fire resistance, and low smoke and toxic gas emission, of carbon fibre reinforced PEEK (Chapter 9), combined with stiffness, strength and durability, have attracted significant attention to this composite as a material system for naval construction. Most notable of such programmes is the vision for building submersibles from thermoplastic composites. As is the case with hydrogen fuel tanks, part of the attraction is to be able to carry out fabrication of very large structures over a long period of time without the need to consider the 'shelf life' of the material and without the requirement to build an autoclave big enough to 'cure' the structure. The ability to weld thermoplastic composite materials may also prove attractive to the shipbuilding industry. The relatively high cost of composite materials such as CF/PEEK in comparison to conventional material of marine construction may limit their use in that industry initially to specialized applications, but the property spectrum available from these materials may stimulate new design, which, in turn, could provoke the development of lower cost thermoplastic materials designed to the specific needs of the industry.

Applications of Differential Scanning Calorimetry and Polymer Characterization

Applications of DSC fall into a broad category of materials characterization, including thermal transitions in polymers: Tg, Tm; curing reactions and kinetics of thermosets, oxidation stability of lubricants and polymers; purity of pharmaceuticals and organics; specific heat capacity of materials and catalyst efficiency. The present article deals with evaluation of some of these parameters:

Specific Heat Capacity Measurement

Heat capacity is the amount of heat required to raise the temperature of a material. It is generally provided as specific heat capacity where heat capacity data is normalised to mass and temperature range. Thus, the units of specific heat capacity are joules per kilogram kelvin (or calories per gram degree celsius). Specific heat capacity information is tabulated at specific temperatures for it is a function which changes with temperature.

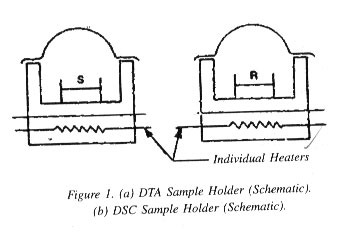

Differential Scanning Calorimetry, (DSC), reports heat flow as a function of temperature, is an excellent tool for the measurement of specific heat capacity. The measurement is made by heating a test specimen at a known and fixed rate. Once dynamic heating equilibrium of the specimen is obtained, the heat flow is recorded as a function of temperature. This heat flow, normalised to specimen mass and heating rate, is directly proportional to the specimen's specific heat capacity. In practice, two thermal experiments are required for each measurement. In the first, a baseline run is performed on only empty sample pan and lid. In the second run, the best specimen is enclosed in the pan and lid. The specific heat capacity information is derived form the difference between the two resulting thermal curves.

Heat flow calibration of the apparatus is also required. This is obtained by running baseline and experiment of traces for a material whose specific heat capacity is well known. Sapphire (a-alumina) is the calibration material of choice since it is readily available, and its specific heat capacity is known to five specific figures.

Calculations

The governing relationship for calculation of specific heat capacity is given in equation :

Cp (lit) is the reported literature value of specific heat capacity of the standard sample, while Cp(obs) is the experimentally observed value under the same conditions as are to be used in the determination of the unknown.

DSC Curing Kinetics

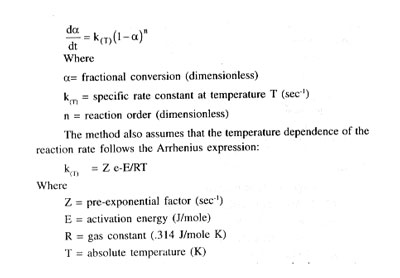

The Borchardt/ Daniels B/D DSC Kinetics Program permits the calculation of activatin energy (E), pre-exponential factor (Z), heat of reaction (H) and order of reaction (p) from a single DSC scan of a reactin exotherm.

Principle of Operation

The method assumes that the reactin follows order kinetics, i.e., obeys relationship:

The DSC exotherm is used to measure the two basic parameters required to solve these two equations:

- the reaction rate da/dt, obtained by dividing the peak height at temperature T by the total peak area; and

- the equation unreacted (1-a), obtained by measuring ratio of the partial area at temperature T to the toal peak area, to obtain a and then substracting this value from unity.

Applications

The B/D DSC kinetics method is applicable to determination of reaction rate information for such exothermic reactions as:

- Thermoset curing

- Chemical decomposition

- Thermoplastic polymerization

DSC Thermal Stability Kinetics

The ASTM E6988 DSC method measures exothermic maximum temperature variation with changes in linear programmed DSC heating rate. Several experiments are run at different heating rates (3 or more), between 1 and 20 K/min. and the temperature shift of the peak maximum is used to compute the kinetic constants.

The calculations make three assumptions:

- The peak maximum represents a point of constant conversion for each heating rate.

- The temperature dependence of the reaction rate constant obeys Arrhenius equation.

- The reaction is first order.

- Each of these assumptions can be expressed mathematically :

E=-2.16RXd(log b)/d(1/Tm)

Where: E = activation energy

R = gas constant (8.314 J/mole.K)

b = heating rate (K/min)

Tm = peak maximum temperature (K)

k = Z e(-E/RT)

Where: k = specific rate constant (min-1) at temperature T

Z = pre-exponential factor (min-1)

T = absolute temperature (K)

da/dt - K(l-a)

Where a = fractional conversion

t = time (min)

The solution to the first equation is obtained from measuring the slope of the log versus 1/Tm plot followed by computer literative calculation to define the value for the activatin energy (E). The pre-exponential factor (Z) is then calculated from the equation

Where T and b are obtained from a mid range heating rate.

Applications

This method is broadly applicable to exothermic reaction of these types:

- Decomposition of thermally unstable materials.

- Estimation of hazard potential of process reactions.

- Curing of thermosets.

- Polymerization of thermoplastics.

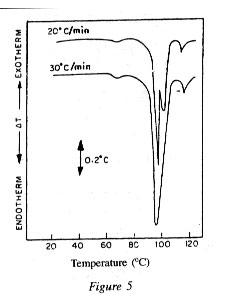

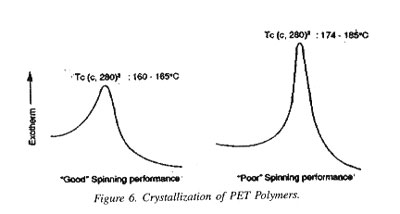

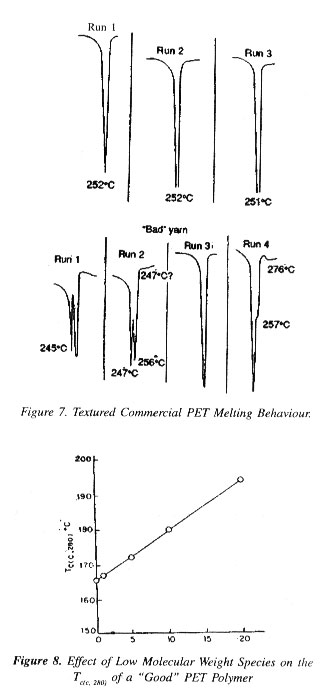

Degree of Crystallinity and Melting Point (Tm)

One of the most widely used application of DSC is the determination of Tm and degree of crystallinity of thermoplastic polymers. Since the DSC directly measures the amount of energy absorbed by the sample during melting the total area beneath the curve is directly proportional to the heat of fusion of the sample (DH). By ratio-ing the heat of fusion calculated with the DSC to the heat of fusion of the 100 : crystalline sample, the degree of the crystallinity of the polymer is readily calculated. For example the heat of fusion of a 100: crystalline sample of high density polyethylene is generally recognised as 286.186 J/g and if DH for a sample of HDPE is found as 185.9 J/g then % of crystallinity of the material would be 185.9/286.186 = 64.9% crystalline. Thus from a single scan, the melting point, heat of fusion and degree of crystallinity of a thermoplastic polymer can be determined.

Statement of the Problem

A.Polymer pellets manufactured under supposedly identical condit tions yield yarn of either good or poor spinning performance.

B. Non-thermal and some thermal methods failed to show differ ences characteristic to the spinning performance.

Condensation Polymerization or Step-Growth Polymerization

1. Functionlity Principal

Polymerization may be generally defined as intermolecular reaction between bifunctional or polyfunctional compounds (covering olefins and related compounds) avoiding formation of ring or cyclic structures and in a manner that makes the process functionally capable of proceeding to infinity. Functional groups or atoms, through disappearance of which polymerizations of different kinds take place are: reactive hydrogen atom (-H), hydroxyl group (-OH), carboxyl group (-COOH), amino group (-NH2), halogen atom (-Cl, -Br), isocyanate group (-NCO), aldehyde group (-CHO), double bond (C=C), etc.

According to the functionality principle and concept, for polymerization to take place, each of the reacting molecules must be at least bifunctional, giving average functionality for the system as 2. For reacting compounds containing two different kinds of functional groups, the average functionality is calculated on the basis of stoichiometric equivalence of the two kinds of functional groups. Thus, for reaction between a dicarboxylic acid and a trihydric alcohol, to strike stoichiometric equivalence of -COOH and -OH groups, the acid and the alcohol should be taken in a molar ratio 3:2, which would express the average functionality for the system as 12/5, i.e., 2.4. On this basis, any system consisting of a polyfunctional compound (functionality 3 or more) bearing a given kind of functional group (say, -OH) and a related monofunctional compound bearing a different kind of functional group (say, -COOH) would always give an average functionality less than 2. So, for any system, if one type of the reacting molecules is monofunctional, then the system would fail to produce polymer molecules. On consideration of functionality, a double bond (C=C) is bifunctional, as on thermal or photoactivation, the bond may open up to yield a diradical intermediate.

2. Types of Polymerization

Polymerization or growth of the polymer usually takes place by two basically different mechanisms. Depending on the mode of formation, one kind of polymerization is called condensation polymerization or step-growth polymerization, and the other kind is known as addition polymerization or chain-growth polymerization. The physicochemical aspects of condensation polymerization will be the subject matter of this chapter.

3. Basic Characteristics of Condensation or Step-Growth Polymerization

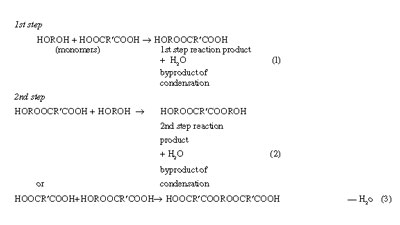

Condensation polymerization takes place under suitable conditions allowing bifunctional or polyfunctional molecules to condense intermolecularly in a manner that the growth of the molecule or chain extension takes place in controlled, distinguishable steps and the process is normally associated with the formation of condensed interunit chemical links and liberation of a small byproduct such as H2O, HCl, etc, at each step of reaction. Formation of a polyester by condensation polymerization or what may be alternatively termed as a polycondensation process between bifunctional monomers eliminating water as the byproduct of condensation may be cited as a typical example:

Formation of a Polyester

The condensation process beyond the first step need not necessarily involve reaction with one of the monomers. Condensation products of all the successive steps retain the bifunctional character, and each bifunctional species formed and remaining into the system at any point of time or extent of reaction is capable of reacting with any other bifunctional species including another of its own size or an unreacted monomer molecule, and the elimination of a molecule of H2O as a byproduct in each step remains a common feature. One more step of condensation results in the loss of one more bifunctional species and as a consequence two functional groups, one of each kind, are lost in each step. The formation of a long-chain molecule of degree of polymerization n, where n has a large value, may be expressed as follows, combining (2n-1) successive steps of condensation:

n HOROH+n HOOCR'COOHR

HO-[- ROOCR¢COO]n-H + (2n - 1) H2O (4)

The chain-growth process at any point of time may be represented by a general equation as follows:

SMn + ZMm ® ZMn+m + H2O (5)

where n and m may have any integral value between 1 and a. For the monomer, the value of n or m is 1.

For a hydroxy acid, the reaction would be written as:

n HORCOOH ® H-[-ORCO]n-OH + (n - 1) H2O (6)

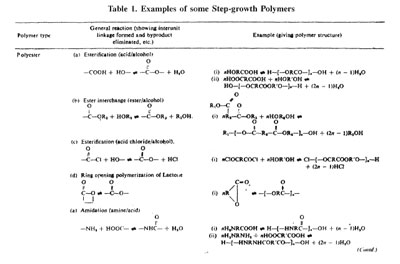

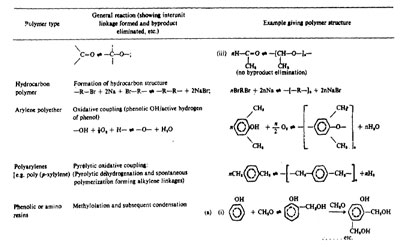

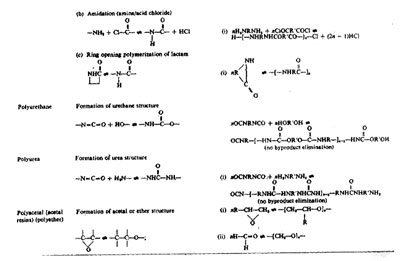

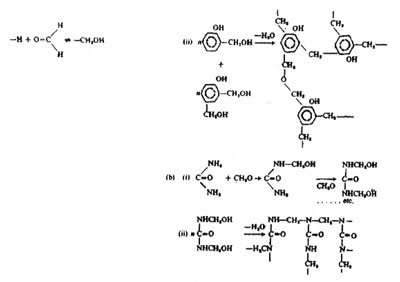

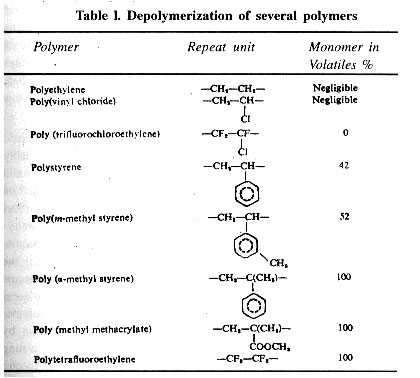

Examples of some step-growth polymerization are given in Table 1.

4. Relationship between Average functionality, Extent of Reaction and Degree of Polymerization

W.H. Carothers derived a general expression, relating average functionality (f), extent of reaction (p) and average degree of polymerization (), for polycondensation reactions carried out for a time period t. The expression is commonly known as Carothers' equation.

Let N0 be the total number of reacting molecules initially present giving an average functionality for the system as f. The related functional groups (say, - OH and - COOH) are also considered to be present in stoichiometric equivalence. Let N be the number of molecules present at time t when the extent of reaction is p.

Then, number of molecules lost during the process over the time period t is (N0 - N); for each molecule lost, the number of functional groups lost is 2 (one of each kind) and hence the total number of functional groups lost is 2(N0 - N) against the initial total number of N0 f functional groups.

Hence, the extent of reaction p=2(No-N)/NoF

or P = 2/f (1-N/No)

The average degree of polymerization, Xn, is defined as the average number of structural units per polymer molecule which can simply be expressed as:

combining Eqs. (7) and (8), one obtains

P=2/F(1-1/Xn)

Equation (9), known as Carothers' equation is very important for the understanding and control of the growth of polymers through poly-condensation reactions. The critical extent of reaction pc at the gel point (for Xn ® a) is given by:

5. Bifunctional System

For a bifunctional system, f = 2, equation (9) reduces to:

for p = 1,= = a, which means that for complete reaction, the average degree of polymerization will be infinity; but short of complete reaction, the degree of polymerization is always a finite quantity. Polymers obtained in a bifunctional system is, under all practical situations, linear and hence soluble and fusible. The upper theoretical limit in the degree of polymerization is infinity and this can be attained only in the hypothetical condition of completion of reaction between the functional groups (p = 1). For bifunctional systems, Eq. (10) may be rearranged to express Xn as

Xn=1/1-P

If the mean molecular weight of the repeat unit in the polymer molecules is Mo, then the average molecular weight Mn of the polymer system is expressed as

Mn=Xn.Mo=Mo/1-P

6. Polyfunctional System

A typical polyfunctional system in condensation polymerization is exemplified by the reaction between phthalic anhydride or phthalic acid and glycerol, i.e., by allowing a bifunctional acid to react with a trihydric alcohol. As discussed before, this system is characterized by an average functionality of 2.4.

For this system, Eq. (9) will assume the form:

P=2/2.4(1-1Xn)

We may now easily find out the critical extent of reaction, pc at which gelation or cross-linking would commence, i.e., at which point would first assume a value of infinity; the calculated value of pc, according to Eq. (9a), will be 2/2.4 = 0.83.

Thus, it is clearly seen that at the point of a theoretical extent of reaction p= 0.83, i.e., when the reaction is 83% complete, the polymer being formed in the polycondensation system gets cross-linked and, hence, turns into an insoluble, infusible gelled mass. Technically, such a condensation polymerization can not and should not be allowed to proceed beyond this point (83% completion), or otherwise the reaction mass would turn into an unusable product. In fact, it is advisable to arrest the reaction nearly 10-15% earlier in p to avoid damage of the reaction kettle and to collect a good quality product which would be useful and which could be easily manipulated in subsequent steps.

The usefulness of Carothers' Equation lies in the linking of p, f and in one expression, and in the fact that it can be used to predict gelation in polyfunctional systems. The limitation of the equation is that practically gelation starts even at earlier stages than predicted by the equation because of uncontrolled local conditions in the hot viscous reaction mass. Moreover, this equation is applicable to polycondensation reactions only, and it loses relevance in the context of addition or chain growth polymerization.

7. Molecular Weight Control: Quantitative Effect of Stoichiometric Imbalance on Maximum Attainable Molecular Weight

Condensation polymerization being an equilibrium step process and endothermic in nature in most cases, control of molecular weight can be readily achieved by allowing the reaction to die down at a desired point by withdrawing heat supply or by cooling and further, by allowing the byproduct of condensation to accumulate in the medium. But in any event, the intermediate product may not be adequately stable toward further heating under a favourable condition with respect to further chain extension and gain in molecular weight. Control of molecular weight can be more precisely attained by striking a calculated stoichiometric imbalance of the two types of reacting functional groups. This may be clearly illustrated considering a bifunctional system having monomers of the A-A and B-B types and giving the numbers of A and B functional groups as NA and NB respectively, such that (NA/NB) = r, where r is either equal to 1 or less than 1, i.e., B groups are present in the system in molar excess, if there is stoichiometric imbalance.

The total number of molecules initially present, No is then given by (NA + NB)/2, or NA(l + 1/r)/2. Let us now find out the total number of molecules N left into the system after a specific time period of reaction when extent of reaction for A groups is p, i.e., p is the fraction of A groups which have reacted. The fraction of B groups which have reacted by that time is then given by rp.

The total number of unreacted A and B groups are then expressed as (NA - NAP), i.e. NA (- p) and NB - NBrp, i.e., NB(I - rp) respectively. The total number of polymer chain ends is thus, given by [NA (I - p) + NB(l - rp)], i.e., [NA(l - p) + NA(l - rp)/r] The value of N, being one half this number, is given by N = NA[(1 - p) + (1 - rp)/r]/2.

Then,Xn=No/N= NA(1+1/r)/2/NA[1-P)+(1-rp)/r]/2

or Xn=1+r/1+r-2rp

and Lt p - 1,Xn=1+r/1-r

For equimolar proportions of A and B groups, i.e. for r = 1.0 = 1/(1 - p), which is the same as given by Eq. (11). The maximum theoretically attainable degree of polymerization for r = 1.0 is a. But for r ¹ 1.0, and with only, say one mole per cent excess of B groups taken into the system (by taking excess of the related bifunctional compound in calculated amount), and taking the help of equation (15), the maximum attainable becomes:

Xn=1+(100/101)/1-(100/101)=201

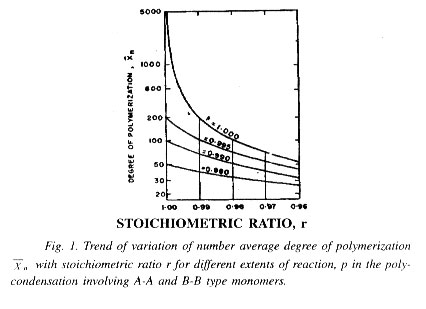

This consideration clearly establishes the importance of stoichiometric equivalence or balance of the reacting functional groups (A and B groups) for attaining high degrees of polymerization, or of introduction of stoichiometric imbalance in order to limit the maximum attainable degree of polymerization to a desired lower level. Fig. 2.1 shows how varies with variation in stoichiometric imbalance, i.e., variation in the value of r.

Considering a bifunctional system and Eqs. (11) and (15) applicable to it, it is clearly realized that the step-growth polymerization must always be carried out to very high conversions, at least to 98%, since a degree of polymerization ]50 is normally required for a polymer to be widely useful. Higher conversions and lesser deviation from stoichiometric balance are required for higher degrees of polymerization. The interdependence of on p and r is given by Eq. (14) and Fig. 1. Closer adherence to stoichiometric equivalence is required for obtaining higher degrees of polymerization. The effect of stoichiometric imbalance is much more pronounced in the very high conversion zone (]98%) than in the lower conversion zones.

8. Kinetics of Step-growth Polymerization

A powerful tool for a good understanding of any chemical reaction is the study of its kinetics. Kinetic analysis of a reaction helps in the understanding of the mechanism of the reaction.

Principle of Equal Reactivity of Functional Groups

Equation (5) describes a characteristic feature of step polymerization. Any two species in the reaction mixture can react with each other. This feature alone complicates kinetic analysis of the overall process, as it involves innumerable separate reactions. However, the kinetic analysis is largely simplified if it is assumed that the reactivities of both functional groups of a bifunctional monomer, e.g., both the carboxyl groups of a dicarboxylic acid, are just the same and that the reactivity of a functional group is independent of the size of the molecule to which it is attached. This means that the reactivity of the specific functional group is independent of the values of n and m. Fortunately, this assumption is more or less valid for all monomers and all larger species that are involved in polycondensation.

The independence of the reactivity of a specific functional group on molecular size is also generally substantiated by the closeness of the rate constants for reactions of a homologous series of compounds (fatty acid) differing from each other only in molecular (weight) size involving esterification with a specific alcohol (ethyl alcohol) in each case.

mineral acid

H(CH2)n-COOH + C2H5OH ---® H(CH2)n-COOC2H5 + H2O

catalyst (HCl)

Table 2, however, shows a decrease in reactivity with increase in molecular size (n) over the very (initial) low range of n and the rate constant of the esterification reaction levels off to a limiting (constant) value for n ³ 3 and maintains constancy and independence of molecular size. This feature of equal reactivity may be generalized and considered applicable to polymerization reactions as well. In the latter case, some complications not encountered in the study of simple compounds may arise, but they may be readily understood and accounted for when considered under proper perspective, i.e., equivalent (molar) concentrations of reacting functional groups, solubility, dilution level, etc. An end (functional) group comprising a terminal reactive centre of a polymer (chain) molecule has a much greater mobility than that of the polymer molecule as a whole. The functional group at the free end would have good degree of mobility in view of the rearrangements that would normally occur in closeby segments of the chain molecule. The collision rate of such reactive functional groups with related functional groups in the neighbourhood will be much the same as for small molecules.

Table 2. Esterification Rate Constants, k at 25°C for Homologous Series

Molecular size AB nkÃ-104kÃ-104 122.1_ 215.36.0 37.58.7 47.58.4 57.47.8 6-7.3 87.5 97.4 117.6 157.7 177.7

All k values are in unit of (gram equivalent/litre)-1, sec-1. A-Esterification between monocarboxylic acids, H(CH2)nCOOH and C2H4OH.B-Esterification between dicarboxylic acids (CH2)n(COOH)2 and C5H5OH.

In polymer systems, the medium viscosity, either in melt condition or in solution, is usually much higher than in systems containing only small non-polymeric molecules. Further, the polymer molecules may become insoluble beyond a critical chain length or molecular weight and the low molecular weight byproduct molecules would tend to slowly accumulate in the system causing the equilibrium to shift in favour of the reactants [Eq. (5)]. All these physical factors may affect the polymerization rate quite measurably. The rate at which independent functional groups react to produce chain extension through establishment of a fresh condensed interunit linkage is dependent on three different rate processes: (i) the rate at which the groups diffuse into a cage, (ii) the rate at which they diffuse apart, and (iii) the rate at which the reactive groups trapped in the cage react to produce the new condensed interunit linkage. Thus, in a given time interval long enough to allow diffusion of a pair of reacting groups, the number of related functional groups with which a given functional group may undergo collisions will be less for a group linked to a polymer molecule than for one linked to a small molecule. But what is more significant is that the overall frequencies of collision in either case are much the same. A pair of groups with a lower diffusion rate will undergo more total collisions before diffusing apart. The net outcome of these considerations points to the important conclusion that the reactivity of a functional group is independent of the size of the molecule to which it is linked.

Rate of Step-growth Polymerization

(a) Self-catalyzed Polyesterification. With the idea of equal reactivity of specific functional groups independent of molecular size, the consideration of rate of step-growth polymerization becomes easy. The formation of a polyester from a dicarboxylic acid and a diol may again be taken as an example, for simplicity. This reaction is prone to catalysis by mineral acids. But in the absence of an added mineral acid such as H2SO4 or HCl, the reactant carboxylic acid itself acts as a catalyst; for each step of reaction between a -COOH group

-COOH -COOH + HO- ----® - COO - + H2O (catalyst)

and an alcohol (-OH) group, a second COOH group from the reactants acts as a catalyst. The rate of the reaction can be measured by measuring the rate of disappearance of the carboxyl groups:

Here, k is the rate constant of the reaction given by equation (16). Considering equimolar presence of carboxyl and hydroxyl groups, and c giving the concentration of each group at a given point,

or on integration, Eq. (2.19) gives:

If co is the initial concentration of each kind of functional group and p is the extent of reaction, i.e., fraction of a given functional group that has reacted at time t, then

c = c0 (l - p)

By combining Eqs. (21) and (20), we get

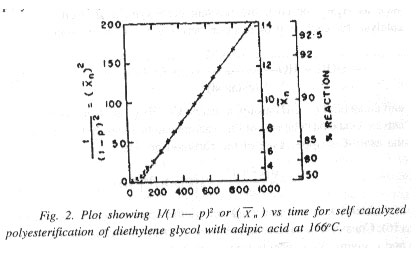

Equation (22) prescribes linearity of the plot of 1/(1 - p)2 vs time. In the case of self catalyzed polycondensation (polyesterification) of diethylene glycol and adipic acid at 166oC, as studied by Flory, the linearity is found to be strictly followed only over the range of nearly 80-94%. Below or above this range of extent of reaction, the experimental points deviated from the third order plot. Equation (22) actually shows a linear relationship between square of the average degree of polymerization, ()2 with time of polycondensation.

It may be mentioned here that the initial nonlinearity is not limited to polyesterification; the initial deviation from the third order linear plot is characteristic of esterifications in general.

Over the initial 50-80% conversion range, a very significant change takes place in the reaction medium, although the average growth in size of the molecules remains far too low. A large change in the polarity of the reaction mixture, however, takes place due to the disappearance of a large fraction of the polar carboxyl groups resulting in the formation of less polar ester linkages. This definite change in polar nature of the reaction medium has a major role to play in causing the deviation in question. But the exact manner or mechanism in which the rate of esterification is affected as a consequence of this polarity change is not very well understood.

The deviation from linearity in the high conversion region (]94%), however, arises as a consequence of other factors including loss of reactants through degradation or volatilization, or even cyclization and other side reactions. Such losses of reactants are likely to be of much less importance in the initial stages. Difficulty in removal of the byproduct of condensation (water) from the reaction medium due to the very high viscosity it assumes in the later stages is also an important contributing factor in decreasing the reaction rate with increasing extent of reaction beyond 94% conversion.

(b) Polyesterificationi Using Strong. Acids as Catalysts. The direct or self-catalyzed polyesterification is slow and sluggish, considering slow increase in molecular weight or average degree of polymerization and this is understood to be a consequence of the third order kinetics. A better result and a faster rate of chain growth is, however, achieved by adding a small amount of a strong acid such as sulphuric acid, p-toluenesulphonic acid, etc. as a catalyst which remains undepleted in the system with progress of the reaction. The rate of disappearance of COOH groups can then be expressed as

For stoichiometric equivalence of the two functional groups and taking c as the concentration of either group the equation (23) may be written as

where k' is the overall rate constant. On integration, and making use of Eq. (21), the following expressions, relating extent of reaction p or degree or polymerization with time of reaction, t, are obtained:

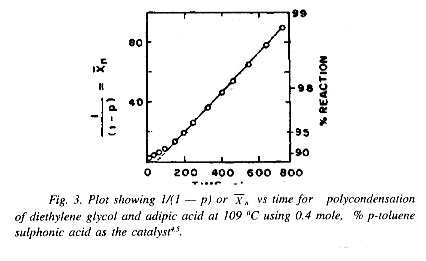

c0k¢t = - constant or c0k¢t = n - constant

A plot of 1/(1 - p), i.e. , vs time, would be linear according to Eqs. (25) and (26). Data relating to polymerization of diethylene glycol and adipic acid catalyzed by p-toluenesulphonic acid as observed by Flory4 are shown in Fig. 3. The plot shows the experimental variation of , the average degree of polymerization with time of polycondensation at a given temperature. Comparison of Figs. 2 and 3 clearly shows that the polyesterification process is much more readily and economically accomplished when an external strong acid catalyst is used. Not only the linearity of vs time plot is very closely maintained, particularly in the more important high conversion zone, but also the rate of increase of with time of reaction is much higher. The second order kinetics find good experimental support up to nearly 98.9% conversion corresponding to value of approximately 90 or a molecular weight of nearly 10,000. This approach of kinetic analysis, however, shows that the reactivities of the carboxyl and hydroxyl groups remain practically unchanged despite growth of the chain molecules to a fairly big average molecular size and a big increase in medium viscosity as a consequence.

Step-growth polymerization other than polyesterification may proceed at desired rates in presence of external acidic or basic catalysts or as uncatalyzed reactions. Irrespective of the approach and situation prevailing, the basic and overall kinetics will be much the same as detailed above for polyesterification. For stoichiometric proportions of the two types of reacting functional groups, say A and B groups, Eq. (25) would be useful to reasonably describe and analyze the kinetics in the respective systems. Whether or not the reacting monomers are of the A-A and B-B types or simply of the A-B types, the observed kinetics will be the same.

Copolymerization and Techniques of Polymerization

1. Concept of Copolymerization

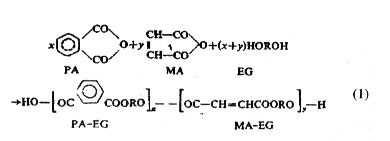

A polymer whose chain molecules are composed of more than one kind of repeating chemical units is commonly called a copolymer. A simple case of a step-growth copolymer is the linear unsaturated polyester formed by inter-molecular condensation of a mixture of phthalic acid (anhydride) (PA) and maleic acid (anhydride) (MA) with a given diol, say ethylene glycol (EG) resulting in what may be termed as a copolyester with at least two distinctly identifiable repeating units in the chain molecules:

Equation (1), showing formation of a copolyester by a polycondensation process clearly identifies two types of repeating chemical units, (PA-EG) and (MA-EG), though in a very oversimplified manner. In the actual copolymer the two types of distinguishable chemical units would normally appear at random along the chain, and the overall composition would depend on the relative values of x and y. Similarly, one can prepare step-growth copolymers with different interunit chemical linkages by proper selection of combinations of different bifunctional monomeric species bearing, -OH, -COOH, -NH2, -NCO or other functional groups, and using two, three or all the functional species simultaneously or in a phased manner in the presence or absence of a related polyfunctional and monofunctional species during the synthesis. However, polycondensation leading to formation of copolymers from this kind of complicated mixtures of monomeric species is of little or rare practical importance or relevance. More relevant step-growth copolymerization systems involve formation of copolymer structures with a specific interunit linkage such as amide (-CONH), ester (-COO-) urethane (-NHCOO-), etc., following the approach as in Eq. (1). It may also involve chain extension and/or cross-linking reaction introducing similar or different kinds of interunit linkages, using low molecular weight linear or branched polymers and selected bifunctional monomeric species. Examples of this kind of step-growth copolymers are found in the making of polyester urethanes or polyether urethanes, using low molecular weight performed linear polyesters or polyethers with hydroxyl end groups and allowing them to further react with each other through diisocyanates leading to chain extension and producing useful elastomeric products commonly known as

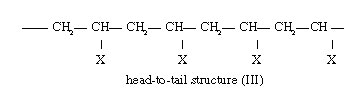

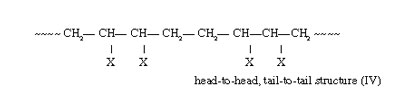

An altogether different kind of copolymer is obtained by polymerization of two or more vinyl and related monomers, all taken together in a reaction vessel. The copolymer molecules contain segments of all the monomers used in their structure, usually in a calculable proportion depending on many factors including the feed monomer composition, the chain-growth mechanism and the inherent reactivities of the monomers with a given chain carrying species.

The number of reactions to be necessarily considered to describe the copolymerization of more than one monomer increases geometrically with increase in the number of participating monomers, giving increasingly varied and complicated structures of the copolymer molecules at the same time. A case of a binary copolymerization involving the two monomers Mî and M2 may be simply represented as:

nM1 + mM2 ~~~~ (M1)n-(M2)m ~~~~

monomer mixture copolymer

The structure of the vinyl copolymer shown in Eq. (4) is far too simplified, however; the two monomer units appear in the copolymer structure in a random sequence in general.

2. Binary Copolymerization of Vinyl Monomers by Free Radical Mechanism

Analysis of the System and the Reactions Involved

In a free radical copolymerization, the number of chain radicals to be considered is given by the number of monomers present and the reactivity of a chain radical is practically determined by the free radical bearing terminal monomer unit and the size and chemical nature of those preceding the radical bearing terminal unit in the chain is considered to be of little consequence in this context.

In a binary copolymerization, therefore, two different chain radicals can be identified and each radical being capable of adding both the monomers, though not usually or necessarily with equal or comparable ease, the system is characterized by four simultaneously occurring propagation reactions. With two different kinds of chain radicals, and considering termination taking place only bimolecularly, the process is associated with three different chain termination reactions along with the possibility of several chain transfer reactions. Chain initiation takes place by reaction of primary radicals (derived from decomposition of the radical initiator used) with either of the monomers present with almost equal ease and efficiency in general or else, in the absence of an initiator, by thermal or photo activation of either monomer with different relative ease depending on the chemical nature of the monomers used.

Kinetics of Chain Propagation in Binary Copolymerization and Copolymer Composition

The four chain-propagation reactions in a binary copolymerization may be described by the reaction scheme (5) shown below:

k1,1 + M1 ® M1

k1,2 + M2 ® M2

k2,2 + M2 ® M2

k2,1 + M1 ® M1

Here, M1 and M2 are the two monomers, and M1 and M2 represent the chain radicals of all sizes with free radical bearing terminal units M1 and M2, respectively. k1,1 and k1,2 are rate constants for homopropagation and cross-propagation reactions respectively involving M1; likewise, k2,2 and k2,1 refer to the homopropagation and cross-propagation rate constants respectively involving M2. For a given rate constant, the first numeral is indicative of the reacting chain radical and the second numeral indicates the reacting monomer. Homopropagation relates to reaction between like radical and monomer and cross propagation relates to reaction between unlike radical and monomer.

Neglecting monomer consumption in the initiation step, the rates of consumption of the two monomers are written as

-(d[M1]/dt)=K1,1[M1][M1]+K2,1[M2][M1]

-(d[M2]/dt=K1,2[M1][M2]+K2,1[M2][M2]

An expression describing relative incorporation of the two monomeric units in the copolymer may be conveniently obtained by elimination of the radical concentration terms using the steady-state concept for each chain radical and then combining Eqs (6) and (7). Under steady state, the concentration of M1 and M2 remaining constant, the rates of interconversion of chain radicals must be equal, which prescribes that rates of reactions (ii) and (iv) of scheme (5) are equal, i.e.,

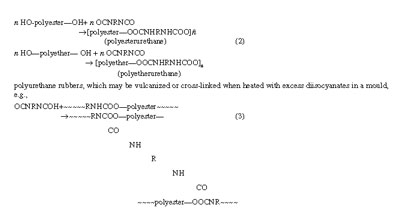

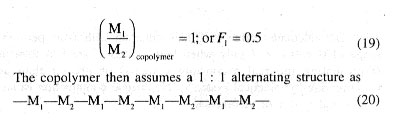

Equation (13) is known as the copolymer composition equation or simply the copolymer equation relating the copolymer composition and feed monomer composition with the help of the kinetic parameters r1 and r2, commonly called the monomer reactivity ratios. Equation (l3) clearly expresses that the copolymer composition is dependent on the molar ratio of the two monomers in the feed (but not actually on the absolute concentrations of the two monomers) and on the kinetic parameters r1 and r2, i.e., the monomer reactivity ratios. The copolymer equation may also be expressed as:

Significance of Monomer Reactivity Ratios

Examination of one or the other forms of copolymer equation clearly shows that with a knowledge of the feed monomer composition, the copolymer composition may be easily calculated if the monomer reactivity ratios r1 and r2 are known. The value of r1 ] 1 means that the chain radical has a preference to add the like monomer, i.e., M1 over the unlike monomer, M2, and r1 value [ 1 means just the opposite. The same concept applies to r2, which gives relative preference of chain radical M2 to add the like monomer (M2) over the unlike monomer (M1).[/P]

The absence of the initiation and termination rate constants in the copolymer composition equation, makes it readily apparent that the (instantaneous) copolymer composition is independent of rate of initiation and hence of the overall rate of polymerization and of initiator concentration. The composition is also not measurably affected in most cases due to the presence of solvents or other additives, indicating that the kinetic factors controlling the copolymer composition, i.e., the monomer reactivity ratios r1 and r2, remain unaffected by variations in initiator concentration, the overall rate of reaction and by the presence of various additives and solvents. They also usually remain unaffected even in heterogeneous systems as long as the reacting monomers are evenly distributed between the phases. However, the composition of copolymer would vary for differential distribution of monomers between phases. The values of r1 and r2 also change significantly for a drastic change in the mechanism of chain propagation from free radical to ionic, and even for ionic mechanism, from cationic to anionic mode of chain propagation. The copolymer equation has been found applicable to almost all comonomer combinations and equally applicable and relevant to radical, cationic and anionic systems, despite wide variations in r2 and r2 values depending on the mode of chain propagation. In radical copolymerization, the effect of temperature on monomer reactivity ratios is small or marginal in view of relatively low activation energies of radical propagation reactions and small differences in activation energies of different propagation reactions.

3. Types of Copolymerization

Ideal Copolymerization

It is the widespread observation and experience that the mole fraction F1 is seldom equal to f1 and as a consequence of this feature, both f1 and F1 keep on changing with progress of copolymerization. The copolymer produced over a specified time period or range of conversion will consist of a mixture of copolymer molecules differing progressively in their compositions (F1).

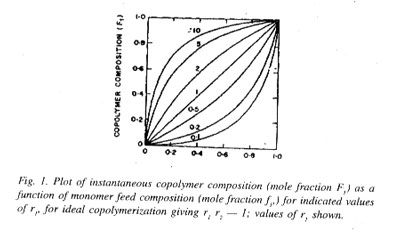

In Fig. 1, plots of F1 vs fi for several cases of ideal copolymerization are shown and the values of r1 (= 1/r2) for each curve are given. For r1 = 1, the composition curve reduces to a straight line given by the diagonal and representing a special case in which r1 = r2 = 1 and hence F1 = f1 For r1 =r2 = k1.1 = k1,2 and k2,2 = k2,1 or in other words, the two monomers are equalry reactive with each radical and the copolymer composition, arising out of a random placement of the two monomers along the chain molecule, is equal to the feed monemer composition over the full range of monomer composition. In case of r1 or r2 i.e., for r1 ] 1 and r1 [ 1, or r1 [ 1 and r2 ] 1, one of the reacting monomers is more reactive than the other toward the two propagating species, and consequently, the copolymer formed will incorporate randomly a higher proportion of the more reactive monomer in its chain structure. The copolymer is proportionately richer in M1 in comparison with the feed monomer mixture for r1 ] 1, and just the opposite composition characteristics would result for r2 ] 1, i.e., for r1 [ 1. With large differences in the reactivities of the two monomers, (i.e., in the r1 and r2 values) the formation of copolymer sequences becomes progressively difficult as a consequence of very fast depletion of the more reactive monomer from the monomer mixture. Thus, for r1 = 0.1 and r2 = 10, giving r1r2 = 1.0 copolymers incorporating good amounts of M1 in its structure is difficult to obtain.[/P]

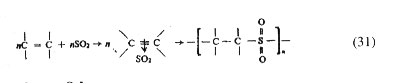

shown in chain sequence (20) irrespective of the feed monomer composition. Copolymerization of stilbene (C6H5-CH=CH-C6H5) or of allyl acetate with maleic anhydride may be cited as examples closely resembling the case of alternation in copolymerization. Almost a perfect brand of alternation is shown by copolymers of sulphur dioxide and certain olefins, cycloolefins or vinyl compounds; they are commonly known as polysulphones and are obtained by radical polymerization of the respective monomer in liquid sulphur dioxide. The alternation is thought to arise as a consequence of self-polymerization of the 1 : 1 complex formed in situ between the olefin or related monomer (donor) and sulphur dioxide (acceptor).

Azeotropic Copolymerization

Some theoretical curves showing copolymer compositions (F1) for various feed monomer compositions (fi) corresponding to different r1 and r2. values, where r1r2 [ 1, (and also for some hypothetical cases given by r1r2 ] 1) are shown in Fig. 2. It may be seen that for both r1 and r2 [ 1 (or ] 1), the curves intersect the diagonal, i.e., the line representing F1 - f1. The point of intersection for a given system corresponds to a condition in which polymerization proceeds without change in composition and the composition of the polymer being formed is just the same as that of the monomer mixture at that point. Copolymerization of these critical mixtures of monomers is commonly known as azeotropic copolymerization. The critical monomer composition is then given by:

4. Average Copolymer Composition

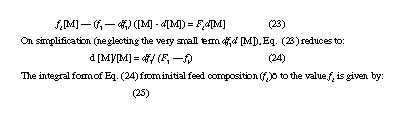

The average composition of a binary copolymer obtained by polymerization of the two monomers M1 and M2 together over a finite range of conversion is conveniently calculated following the method and approach of Skeist. If [M] is the total or overall moles of the two monomers in the initial mixture, then [M] = [M1] + [M2], and initially [M1] is f1 [M]. For d[M] moles of monomers converted to polymer, the number of moles of M1 polymerized is F1d [M]. As during the process f1 changes by df1, and considering F1 ]f1, i.e., the copolymer formed is richer in M1 than the feed monomer mixture, the unreacted monomer mixture will contain (f1 - df1) ([M] - d[M]) moles of monomer M1. The moles of M1 going into the copolymer structure being equal to the difference in the moles of M1 in the monomer mixture before and after the reaction, one readily obtains

calculation of F1 as a function of f1 may be readily done with the help of Eq. (15) for a given set of values of r1 and r2. A knowledge of (F1 - f1) then permits graphical integration of Eq (4.25) to give the required degree of conversion {([M]o - [M])/[M]õ} where [M]õ is the initial value of [M], for a change in the feed composition from (f1)õ to f1. By successive application of this method for different values of f1 a relationship between f1 and degree of conversion may be obtained. The integral composition of the cumulative mass of copolymer formed during a given conversion stage is readily calculated from the shift in the value of f1 over the corresponding time span. This allows graphical expression of the instantaneous composition of the copolymer as a function of conversion.

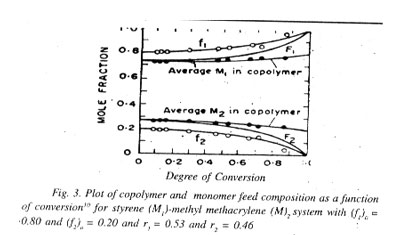

Figure 3 shows how the average composition of the copolymer changes with degree of conversion for the styrene (M1) methyl methacrylate (M2) system for a case specified by (f1)õ = 0.80 and (f2)õ r1= 0.20 and r2 = 0.53 and n = 0.46. The instantaneous value of F is seen to follow f to unity (for M1) or to zero (for M2), but the average copolymer composition is seen to change marginally in comparison, becoming slightly but progressively richer in styrene with conversion.

For laboratory experiments, copolymerizations done to low conversions (within 5%) are better understood with the help of Eq. (15), in view f and F values as well as the average copolymer composition remaming practically unchanged over the limiting conversion zone. But this is impractical for an industrial process where replacement or replenishment of the depleting monomer at regular intervals is usually practised to minimize or eliminate variations in the monomer composition. For styrene-methyl methacrylate system, the reactivity ratios are quite close; so, it gives rise to rather limited variations in the average copolymer composition. But even such systems are also subject to the question as to just how much variation in the average composition can be tolerated without detrimental effects on the useful or desirable properties of the copolymer product. The replenishment of the depleting monomer (i.e., the more reactive monomer) often through continuous addition is usually worth the added cost that it entails.

5. Determination of Monomer Reactivity Ratios

For experimental evaluation of the monomer reactivity ratios, r1 and r2 copolymerization of the two monomers M1 and M2 at a number of feed compositions are done to low conversions, usually within 5%; the copolymers formed are then isolated, purified usually by repeated precipitation and finally analyzed for their compositions employing elemental analysis, determination of reactive groups, tracer (radioactive) technique, spectroscopic methods, etc. The feed and copolymer composition data may then be treated according to the following approaches for evaluation of r1 and r2:

(i) Trial and error or curve-fitting method. The method utilizes the experimental data on theoretical curves (F1 vs f1) to find which theoretical curve gives the best fit on trial selection of r1 and r2 values. This turns out to be a poor and tedious approach and precise determination of r1 and r2 is often difficult in view of insensitiveness of the composition curve to small changes of r1 and r2.

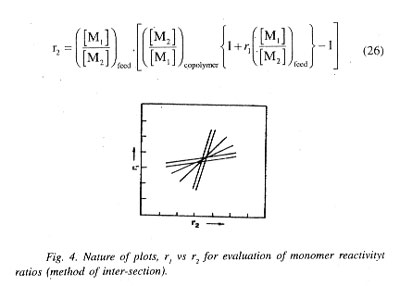

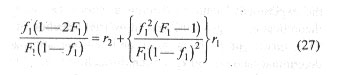

(ii) Method of intersection. For this method Eq. (13) is rearranged to express r2 in terms of r1 by the linear relationship given by Eq. (26):

Plot of calculated values of r1 for assumed values of r2 or vice-versa for each experiment with a given feed composition gives a straight line. Theoretically, different linear plots for different experiments would intersect at a common point to allow evaluation of the r1 and r2 values for the given monomer pair from the intersection point, Fig. 4. In case there are experimental errors, the lines may not intersect at a single point and in that event the actual r1 and r2 values are obtained by averaging or from the central point of the contour given by the different points of intersection.

With known values of f1 and corresponding F1 values determined by experimental analysis, left hand side of Eq. (27) when plotted against the coefficient of r1 would yield a linear plot and the r1 and r2 values for the monomer pair would be given by the slope and intercept of the plot, respectively.

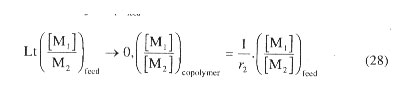

(iv) The method of limiting feed composition. Success of this method depends on finding very sensitive method of analysis of composition of copolymer prepared under conditions of very low values of ([M1]/[M2])feed such that the feed ratio progressively approaches zero. Equation (4.13) or its alternative form, Eq. (26), would then reduce to a more simple form given by Eq. (28). Likewise, the ratio given by feed composition ([M2]/[M1])feed

to copolymer composition ([M2]/[M1])copolymer may be equated to r1 for [M2] 0. Plot of the left hand side of Eq. (28) aganist the feed ratio, ([M1]/ [M2]feed yields a straight line passing through the origin and r2 is calculated from the slope of the linear plot. Calculation of r1 then readily follows from a knowledge of r2.

Monomer reactivity ratio of some selected binary copolymerization systems are listed in Table 1.

Rate of Copolymerization

For treatment of copolymer composition, it was sufficient to consider the four propagation reactions or the two relative propagation rate constants, i.e., the monomer reactivity ratios, r1 and r2 for a binary system. Evaluation of overall rate of copolymerization requires consideration of the rates of initiation (R1) and termination (Rt) at the same time. Primary radicals released into the monomer mixture through initiator decomposition react with each monomer with nearly the same ease and efficiency so that consideration of two separate types of initiation is not necessary. Three types of termination must be considered assuming bimolecular mechanism involving all possible pairs of radical types. Under steady state condition of all the chain radicals, Ri being equal to Rt, one may write:

The values simply represent the reciprocals of the well known kinetic parameter kp /(2kt)1/2 for homopolymerization of the individual monomers and represents the ratio of half the cross-termination rate constant to the geometric mean of the termination rate constants for like radicals; ] 1 indicates that cross-termination is favoured and [ 1 means just the opposite. The factor 1/2 appearing in the ratio indicates that termination involving pairs of unlike radicals is statistically favoured by a factor of two compared with termination involving pairs of like radicals.[/P]

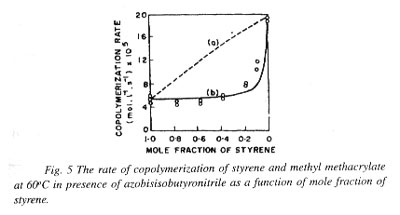

The values of d1 and d2 can be conveniently obtained from the studies of rates of homopolymerization of M1 and M2 using the general relation (-d ln[M]/dt = R1,2/d). The monomer reactivity ratios r1 and r2 are readily determined from studies of copolymer composition. A measurement of rate of copolymenzauon, then, allows calculation of f using Eq. (30a). A falling trend in the rate of copolymerization as compared to the mean of the rates of homopolymerization of the two monomers used follows as a consequence of the usual preference for cross-termination in copolymerization. Figure 5 shows how rate of copolymerization varied with feed monomer composition for a binary monomer system involving styrene and methyl methacrylate for (a) f = 1, showing the theoretical curve and (b) f = 13, showing the experimental points and the theoretical curve. The widespread experience is that the experimental rates of copolymerization fall below the f = 1 line, indicating that f is usually ] 1 and that the cross-termination rate exceeds the geometric mean for rate of termination involving like radicals.

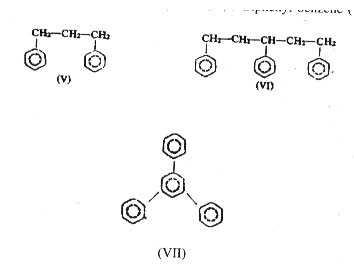

7. Structure and Reactivity of Monomers and Radicals

Nature and number of substituents and the site of the substituents in case the unsaturated (olefinic) monomer bears more than one substituent on the unsaturation have decisive roles to play in determining the reactivity or stability of a specific monomer and the corresponding radical. The substituents influence or modify reactivity or stability by three basic approaches: (i) by activating or deactivating the p bond and thus rendering the monomer less stable and hence more reactive or vice versa, (ii) by imparting enhanced or reduced stability to the derived radical depending on better or limited prospects for resonance, and (iii) by providing different degrees of steric hindrance at the reaction site.

Structure and Reactivity of Monomers

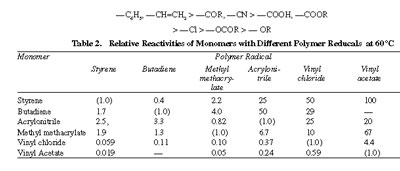

A relative order of reactivities of a series of monomers (Mz) is conveniently obtained by comparing the reciprocal monomer reactivity ratio (1/r1 = k1,2/k1,1) for each of the monomers in the given series with a specific chain radical,. If the rate constant for the reaction of the reference radical with its own monomer is taken as unity, relative monomer reactivities can be readily examined and compared. Related data for a few monomer-radical combinations are listed in Table 2. Thus, the first column under polymer radical of Table 2 compares reactivities of different monomers toward a chain radical having styrene unit as the radical bearing terminal unit, the second column gives a comparative idea of the reactivities of different monomers toward butadiene chain radical and so on. In view of different basis taken for each radical, values for different radicals given in different columns cannot be compared. The order of monomer reactivities is roughly parallel for all radicals, with some exceptions, here and there. The general order of enhancement of reactivity of a monomer by a substi-tuent toward radical attack is as follows:

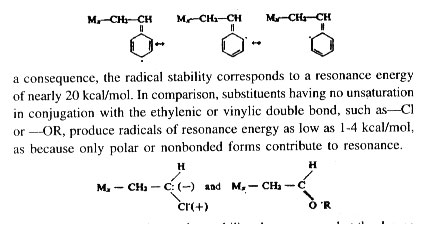

Resonance Stabilization

The relative order of monomer reactivities toward a radical generally corresponds to the relative resonance stabilization of the radical formed on addition of the monomer. The more reactive monomer generally yields a radical of higher stability through resonance. A second substituent on the same carbon atom usually leads to an additive effect on the monomer reactivity or on the resonance stabilization of the corresponding radical.

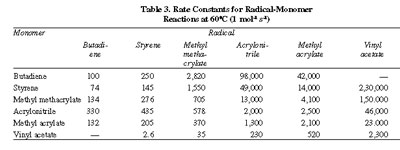

Comparison of reactivities of different radicals toward the same monomer is conveniently done by making use of the absolute propagation rate constant, k1,1 and the reactivity ratio r1. Division of k1.1 by r1 gives an indirect measure of the rate constant k1,2 for reaction between radical and monomer M2. Absolute (propagation) rate constants for several redicals with each of the respective monomers are listed in Table 3. It is clearly seen that the reactivity of the radicals is in the reverse order of that for the monomers. Among the vinyl monomers shown, styrene is the most and vinyl acetate is the least reactive, while styrene radical is the least and vinyl acetate radical the most reactive. The styrene radical owes a high order of stability due to the possible existence of three quinonoid resonance structures, and as

The substituents also tend to stabilize the monomer, but the degree ot stabilization is much smaller for the monomer than for the radical. The resonance stabilization due to conjugation amounts to only about 3 kcal/ mol for styrene and butadiene as against a resonance stabilization to the tune of about 20 kcal/mol for the corresponding radicals.

Radical Reactivity and Steric Effects

The reactivities of different radicals toward a given monomer and vice-versa can be judged and appreciated from a comparison of the respective reaction rate constants listed in Table 3. Quite expectedly, a substituent rendering the monomer more stable confers on the corresponding radical higher reactivity and vice-versa. A substituent's role in enhancing the reactivity of a radical is much greater than its effective role in depressing the reactivity of the monomer. Thus, the vinyl acetate radical is apparently 500-1500 times more reactive than the styrene radical toward a given monomer, but the styrene monomer is only about 50-100 times more reactive than the vinyl acetate monomer. If and represent an unstabilized and a stabilized radical and M and Ms represent an unstabilized and a resonance-stabilized monomer, then the radical-monomer reactivity follows the order:

(R + Ms) ] (R + M) ] (Rs + Ms) ] (Rs + M)

Substituents are also known to influence the radical monomer reaction rate constants from the view point of steric hindrance. This can be well appreciated by considering some of the related rate constant data for monomers such as vinyl chloride (monochloroethylene), vinylidene chloride (1,1-dichloroethylene), 1,2-dichloroethylene and polychloroethylenes, given in Table 4. The effect of a second substituent on the monomer reactivity produces roughly an additive or reinforcing effect for the 1,1-disubstituted monomer, but in the case of a 1, 2 disubstituted monomer, there is a significant decrease in reactivity principally due to steric hindrance.

Table 4. Rate Constants k1,2 for some Radical-Monomer Reaction at 60oC Showing Steric Effect of Substituents in Copolymerization (1 mol -1g-1)

<th colspan='2' align='center'>Radical (M1)

| Monomer (Mg) |

| |

Vinyl Acetate |

Styrene |

| Vinyl chloride |

43,000 |

10.35 |

| Vinylidene chloride |

1,00,000 (68°C) |

95.14 |

| cis-1,2-Dichloroethylene |

1,580 |

0.83 |

| trans-1,2-Dichloroethylene |

9,900 |

4.75 |

| Trichloroethylene |

15,200 |

11.0 |

| Tetrachloroethylene |

1,470 |

0.95 |

k1,2 (= k1,1/r1) values were culculated using k,1,1, i.e, kp value for vinly acetate as about 10,000 and for styrene as 176 and the respective r1 values from the literature.

Among the two 1,2-dichloroethylenes, the cis-isomer is much less reactive than the trans-isomer toward reaction with a given radical in copolymerization because the cis-isomer is less stable and also because the cis-isomer is unable to achieve a completely coplanar conformation in the transition state during reaction with a radical, thus impairing resonance stabilization of the derived radical by the substituent.21

The lower reactivity of tetrachloroethylene in comparison with that of trichloroethylene is analogous to the difference in reactivities between vinyl chloride and 1,2-dichloroethylene. Trichloroethylene is more reactive than the 1,2-dichloroethylene but is less reactive than the 1,1-dichloro derivative i.e., vinylidene chloride.

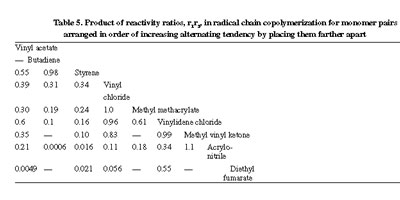

Polar Effects and Alternation

Examination of Tables 2 and 3 reveals that the reactivities of a given monomer to different radicals or of a given radical to different monomers do not exactly follow the same order for different reference monomers or for different reference radicals respectively. Monomer and radical reactivities are interdependent. Deviation of the product r1.r2 from unity and its closeness to zero is taken as a measure of alternating tendency and this enables one to tabulate monomers in order of their r1r2 values with other monomers, as shown in Table 5 in a diagonal manner such that further apart the two monomers are the greater is their tendency to alternate. Monomers with electron releasing type of substituents are placed at the top and those with electron withdrawing substituents at the bottom part of the table. Thus, a specific nature of radical-monomer reaction manifested through alternation is favourably achieved for monomer pairs with dissimilar polarization properties of the substituents.