INDUSTRIAL CHEMICALS,BIOCHEMICALS AND FUELS

Citric Acid

Citric acid or 2-hydroxy-1, 2, 3-propanetricarboxylic acid (77-92-9) was first isolated from lemon juice. Althought it occurs in rather high concentrations in citrus fruits, citric acid is ubiquitous in nature forming as it does an intermediate in the citric acid (Krebs) cycle whereby carbohydrates are oxidized to carbon dioxide. The widespread presence of citric acid in the animal and plant kingdoms is an assurance of it non-toxic nature and it has long been used as an acidulent in the manufacture of soft drinks, as an aid to the setting of jams and in other ways in the confectionery industry.

Uses and Properties of Citric Acid

Citric acid is produced either in the anhydrous form or as the monohydrate. The transition temperature between the two forms is 36.6ºC. Thus the andhydrous form is obtained by crystallization from hot aqueous solutions whereas the monohydrate is obtained by crystallization at temperature below 36.6ºC. Both forms are utilized in commerce.

Sales of citric acid worldwide are divided amongst the principal fields of use approximately as follows : food, confectionery and beverages (75%), pharmaceutical (10%) and industrial (15%).

In food, sugar confectionery and beverages, citric acid is the most versatile and widely used food acidulent. The use of citric acid as a good acidulent depends in part on its strength as an acid. (At 18ºC, K1-8.2 µ 10-1, K2 1.77 µ 10-5 and K5-10-7, Howerver, its pleasant taste and its property of enhancing existing flavours have ensured its dominant position in this market.

Citric acid is able to complex heavy metals such as iron and copper. This property has led to its increasing use as a stabilizer of oils and fats where it greatly reduces oxidation catalysed by these metals. The ability to complex metals combined with its low degree of attack on special steels allows the use of solutions of citric acid in the cleaning of power station boilers and similar installations.

The sequestering action of citric acid is also used in the pharmaceutical field, for example in the stabilization of ascorbic acid. Another large pharmaceutical use is based on the effervescent effect it produces when combined with carbonates and bicarbonates, for example in antacid and soluble aspirin preparations. Citric acid is often used as the anion in pharmaceutical preparations employing basic substances as the active agent.

Citric acid forms a wide range of metallic salts, many of which are articles of commerce. In terms of volume, trisodium and tripostassium citrates are probably the most important. Trisodium citrate is widely used as a blood preservative, where it prevents clotting by complexing calcium. It is also employed as an aid to emulsification in the manufacture of processed foodstuffs, e.g. cheese.

In the areas where there are restrictions on phosphates in detergents trisodium citrate is replacing phosphates in speciality cleaners and heavy-duty liquids.

Ferric ammonium citrate is still used in the treatment of anaemia although other iron salts are increasingly preferred.

Mixtures of citric acid and its salts have good buffering capacity and are extensively used for this purpose in the pharmaceutical, toiletry and food industries.

In a process for the removal of sulfur dioxide from the flue gases of power stations and metal smelters proposed by the US Bureau of Mines, a buffer solution containing principally H2Cit is used as a scrubbing agent. A complex ion, H2CitHSO 2/3, is formed which in a second stage reacts with H2S to produce elemental sulfur. The sulfur is readily separated from the citrate solution which may be recycled. The advantage of using citrate solution which may be recycled. The advantage of using citrate solution in this process is that certain side reactions yielding sulfate and thiosulfate, both giving rise to disposal problems, are substantially inhibited by the citrate.

Citric acid esters of a wide range of alcohols are known. In particular the triethyl, tributyl and acetyltributyl esters are employed as non-toxic plasticizers in plastic films used to protect foodstuffs. Monostearyl citrate can be used instead of citric acid as an antioxidant in oils and fats. It is more easily incorporated than the free acid, and an improved method or preparation has been devised in the authors' laboratories.

PRODUCTION PROCESSES-FERMENTATION

From among the historically used processes for the production of citric acid the following are still important:

A. niger

Surface fermentation using beet molasses ; (ii) submerged fermentation using beet or cane molasses or glucose syrup. Submerged processes using sucrose as carbohydrate source are also belived to be running in areas where sugar is cheap.

Yeast

Submerged fermentation using beet molasses or glucose syrup.

Media

Both beet and cane molasses are very variable in quality both from season to season and from refinery to refinery. In spite of many investigations no clear reasons for this has emerged. Probably because the composition of molasses is so complex. It is necessary, therefore, to make a selection of available molasses on the basis of performance.

In order to obtain good yields of citric acid, particularly when A. niger is used, it is especially important to keep available levels of heavy metals, including iron and manganese, below certain critical levels. This is done in molasses media by making additions of sodium or potassium ferrocyanide. Other inorganic nutrients are supplemented where necessary but most inorganic nutrients are already present in molasses.

Where glucose syrup is employed as carbohydrate source heavy metals are removed by ion exchange. Pretreatment of sucrose-based media by additions of ferrocyanide have also been proposed. In processes where pure glucose or sucrose is used as the substrate, additions of nitrogen, phosphate and other essential nutrients are made.

Yields

The yield of citric acid in the fermentation of expressed as kg citric acid monohydrate per 100 kg carbohydrate supplied. Yields in the range 70-90% on this basis have been reported. It should be mentioned that the theoretical yield of citric acid monohydrate from sucrose assuming no carbon is diverted to biomass, carbon dioxide or other by-products is 123% and that from anhydrous glucose is 117%. Thus up to about three quarters of the supplied carbon is converted to citric acid in a good fermentation.

Surface Process with A. niger

The surface fermentation using A. niger with beet molasses as raw material is still extensively employed by major manufacturers. Although somewhat labour intensive, the power requirements are less than in the submerged fermentation. Bucause citric acid manufactures keep their methods secret, little authorative material has been published.

Beet molasses is diluted with water to a suitable sugar concentration, e.g. 150 kg m-3, and the pH adjusted. An initial pH of 5 to 7 is usually employed because A. niger will not germinate at higher hydrogen ion concentrations. This effect was unknown when media based on sucrose were being used and starting pH values as low as 2 were in some cases employed. The lack of germination in molasses at low pH is ascribed to the presence of acetic acid, which is a normal constituent of molasses. It appears that unionized acetic acid is the species that prevents the germination, acetate being harmless in this respect. Hence the effect of pH.

Additional nutrients and alkali ferrocyanide are then added, and the whole boiled or otherwise sterilized. After cooling, the prepared medium is run down into a series of trays supported on racks in a ventilated chamber. The trays, which are usually made of very high purity aluminium, are filled to a depth of between 0.05 and 0.20 m.

Spores of A. niger are obtained by growing a selected strain on a sporultion medium. The spores are collected and distributed over the surface of the medium in the trays. Sterile air is supplied to the fermentation chamber. The air performs the dual function of supplying oxygen and carrying away fermentation heat and the rate of flow of the air is regulated accordingly. A temperature in the region of 30ºC is often employed. The mycelium forms a coherent felt on the surface of the liquid becoming progressively more convoluted. The removal of the heavy metals by the ferrocyanide severely restricts sporulation. After a period of 7 to 15 days the trays are emptied, the mycelium being at the same time separated from the fermented liquor. The liquors are pumped forward to the recovery section.

Unwanted by-products of the process are gluconic and oxalic acids.

Submerged Fermentations

As indicated above there are a number of variants of this process.

Cultivation of A. niger in carbohydrate media

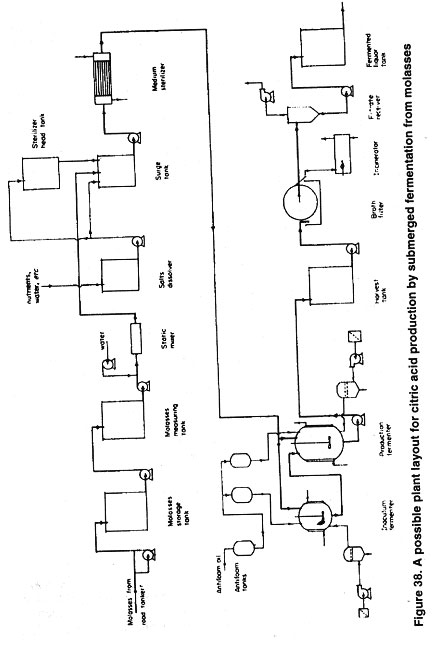

Figure 38 is a flow diagram of the fermentation layout of a possible citric acid plant which consists of a medium preparation section, a fermenter section and a section for separating the fermented liquor from the organism.

The medium preparation (suitable in this case for molasses) shows an in-line sterilization step, but sterilization of the medium in the fermenters is a possible alternative. Where in-line sterilization is used the fermenters are sterilized separately using steam at not less than 1 bar.

In the plant shown, a vegetative inoculum stage is used where spores of A. niger are allowed to germinate in an inoculum medium before being transferred to the main fermentation medium in a larger vessel. In some processes the spores are introduced directly into the main fermentation but in all cases the inoculum stage, or the initial growth stage in the main fermentation. The morphology of the mycelium at this point is crucial according to many reports, not only in relation to the shape of the hyphae themselves, but also in the aggregation of the growth into small spherical pellets. Thus the hyphae should be abnormally short, stubby, forked and bulbous. This state of affairs is brought about by a deficiency of manganese in the medium or the obviously related additions of ferrocyanide ion. The mycelial pellets should be small (0.2 to 0.5 mm) with a hard, smooth surface. Factors leading to the production of such pellets are correct ferrocyanide level, an ion concentration of less than 1 p.p.m., adjustment of pH, adjustment of aeration and agitation, concentration of manganese and amount of spore inoculum. Whether the aggregation of the deformed hyphae into pellets is really necessary is doubtful, especially when stirred fermenters are being used, but the pellet form does give a broth that is more readily mixed.

Where a separate inoculum stage is employed, a suspension of spores of A. nigar, usually grown on a solid medium, is introduced into sterilized medium in the inoculum fermenter. The medium is aerated and, in some processes, agitated and the mould allowed to grow at a temperature of about 30ºC for a period of from 18 to 30 hours as judged by pH level reached or in other ways.

The fermentation medium is prepared and transferred to the main fermenter and the grown inoculum incorporated at the rate of about 1 m3 inoculum to 10 m3 fermentation medium.

Where the inoculum or fermentation medium is based on molasses the initial pH is normally in the range 5 to 7. As mentioned above, most A. niger strains do not germinate or grow at lower pH values in this type of medium. On the other hand lower initial pH values can be tolerated in glucose-or soucrose-based media, and are often used with advantage. There is a lesser chance of infection by adventitious organisms. The fermentation is conducted at about 30ºC.

Two types of fermenter are in common use, namely the stirred, aerated, baffled tank and the aerated tower fermenter which has a much higher aspect ratio than the former and often contains an internal draught tube to promote circulation. Both types are constructed of high grade stainless steel and have provision for cooling. Both designs are sparged from the base with sterile air, although extra oxygen is sometimes used in the tower type. Sometimes superatmospheric pressure in the fermenter is used to increase the oxygen solution rate. The effect of dissolved oxygen tension (DOT) on the citric fermentation has been studied measuring electrodes are usually provided. The kinetics of the citric acid fermentation with A. niger have been reported. A growth phase is followed by a citric acid producing phase during which only a small amount of growth occurs.

Cultivation of yeast in carbohydrate media

In 1965 Tabuchi field a patent for the manufacture of citric acid from technical glucose and molasses in which the organisms claimed were eight genera of yeasts including Candida. The fermentation was carried out at a neutral pH maintained by incorporating calcium carbonate in the medium. A further patent reports yields of about 65% from blackstrap molasses containing calcium carbonate using strains of Candida oleophila. However, it was soon found that a limitation of citric acid yield was the production of quantities of L-(+)-isocitric acid. Efforts were made to select yeast strains not having this defect. Scientist selected Scientist subspecies of Candida guilliermondii producing only small amounts of isocitrate. Claimed a method of obtaining mutants of yeasts giving negligible quantities of isocitric acid wherein the mutants were selected for an inability to grow on media containing a halocitric acid or a precursor thereof. A mutant of Debaromyces calussenii producing a 73% yield from glucose was obtained. Scientist claimed the use of mutants of species of Candida (e.g. C. zeylanoides) requiring a higher iron content in the medium than the parent. Science claimed the use of strains of Candida, Endomycopsis, Torulopsis, Hansenula and Pichia grown in a molasses medium containing µ-chloro- or µ-fluoro-substituted lower alkanoic mono- or di-carboxylic acids or their water soluble salts or amides such as fluroacetate or fluroacetamide. Scientist proposed to cultive species of Candida in media containing glucose or blackstrap molasses to which 1.5 kg m-3 lead acetate had been added, obtaining thereby higher yields of citric acid. Additions of lead acetate, together with either n-hexadecy citric acid or trans-aconitic acid have also been proposed. By using strains of osmophilic yeasts, initial concentrations of sugar as high as 280 kg m-3 may be employed. In this particular process no pretreatment of medium prepared from crude carbohydrates to remove metal ions is apparently necessary. Calcium carbonate, lead acetate and fluoroacetamide are also added as before.

A continuous fermentation process for the production of citric acid from blackstrap molasses using Candida guilliermondii has been described.

The advantages of using a yeast, rather than A. niger, are the possibility of using very high initial sugar concentrations, together with a much faster fermentation. This combination gives a high productivity per run, to which must be added the reported insensitivity of the fermentation to variations in the heavy metal content of the crude carbohydrates that are often used for economic reasons.

Fermenters of the tower type previously described are suitable, but more effective cooling is required because of the rapid rate of heat output during the shorter fermentation.

An inoculum culture is prepared in a smaller fermenter by introducing cells of the selected yeast strain previously grown in slope culture. When the inoculum is sufficiently grown it is transferred to the fermentation medium in the main fermenter. The fermentation is conducted at a temperature between 25 and 37ºC, depending on the organism. The initial pH must not be too low or yeast growth will be impaired, this presumably being the reason for adding the calcium carbonate to the medium. The pH can subsequently be allowed to fall. (In the continuous process the pH is controlled at 3.5 by means of aqueous ammonia.)

The broth is harvested when citric acid accumulation has become uneconomically low.

Nutritional Considerations

The growth of A. niger requires, as would be expected, in addition to a source of carbon, supplies of nitrogen, phosphate, potassium, magnesium and sulfur. In addition, small quantities of zinc, iron, copper and manganese are necessary, as well as olybdenum if nitrate is to be metabolized. When a sufficiency of these nutrients is available the mould grows to its full extent finally entering a sporulation phase. In order that citric acid accumulation can occur to the extent required by a commercial process, neither full growth nor sporulation must take place. This implies a limitation of nutrients. Researchers grew a mould of the A. niger group in continuous culture. They found a sharp maximum of citric acid production at 0.8 kg m-3 NH4NO3 and concluded that nitrogen limitation was an essential requirement for citric acid production. However, demonstrated that cultures otherwise conditioned to citrate accumulation moved out of the growth phase when phosphate was exhausted even when nitrogen was not limiting. Probably either nitrogen or phosphate limitation of effective in inducing citric acid production depending upon strain and other conditions. The positive effect of phosphate limitation would explain the successful use of beet molasses which contain relatively large amounts of metabolizable nitrogen.

The importance to the citric acid fermentation of the correct levels in the medium of the trace elements zinc, iron, copper and manganese has long been appreciated. Optimum additions of iron and manganese were found to be necessary for best citric acid yields and the optima varied from strain to strain. Using a purified glucose medium and the well-known A. niger Wisconsin 72-4 additions of 0.3 p.p.m. zinc and 1.3 p.p.m. iron were optimal. Additions of manganese at any level reduced the yield. Researchers found that manganese carried over in spores, when these were produced on a medium containing manganese, was sufficient to reduce citric acid yields.

The importance of the zinc, iron and manganese concentrations in the medium thus explains the necessity for the ion-exchange purification of glucose solutions or the treatment of molasses with ferrocyanide ions. Scientist have examined the effect of temperature and pH on the precipitation of iron, copper and manganese from molasses solutions. Scientist found that additions of as little as 1 p.p.b. manganese to ferrocyanide-treated beet molasses reduced the yield of citric acid by 10%. Scientist concluded that ferrocyanide ion directly inhibited mould growth as well as removing unwanted heavy metals from molasses. Researchers found that a small excess of free ferrocyanide in the medium after removal of metals led to increased yields are reached the same conclusion.

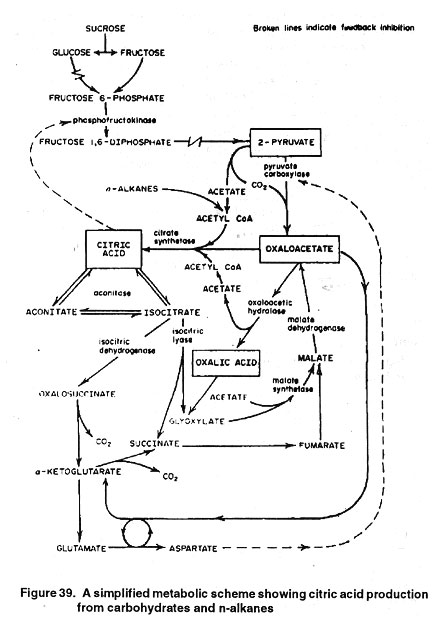

Metabolic Pathways Leading to Citric Acid Formation in A. niger

Figure 39 shows a slightly simplified version of the various enzymatic reactions relating to the synthesis and breakdown of citric acid. Early 14C tracer experiments under conditions giving only moderate yields of citric acid had led to the conclusion that 40% of the acid was produced by a C2, C2 condensation, and 60% via a C1, C3 condensation. Moreover, nearly 40% was produced from recycled C4 acids. Using glucose-3, 414C under good yielding conditions they showed that a near quantative recovery of the labeling was obtained in carbon 4 of the citric acid. Carbon 6 had a specific activity of about 15% of the original. None of the other carbons was labeled to any significant degree. It was concluded that there was no recycling of C4 acids and that the citric acid was formed by an initial symmetrical 3 : 3 split of the glucose and that decarboxylation of one fragment produced a two-carbon compound and finally citric acid was produced by condensation of the two-and four-carbon moieties. Carbon introduced by carboxylation was carbon 6 the specific activity having been diluted by the carbon dioxide pool in the hyphal cells (see Figure 39).

Enzymatic Considerations

The previous section has considered tracer evidence and other matters in relation to citric acid accumulation by A. niger but some enzymatic evidence was inevitably adduced. Further evidence of enzymatic activity during the citric acid fermentation together with aspects of the regulation of these activities under conditions of high citric acid yield will now be considered.

The Embden-Meyerhof pathway

The enzymes of this pathway are well attested in A. niger.

The aldolase of A. niger requires zinc for activity and this may explain the often explain the often expressed need for zinc in the fermentation medium. Citrate is a known feedback inhibitor of phosphofructokinase (PFK) and mitigation of this inhibition is obviously required for good citric acid accumulation. Scientist has studied the inhibition of PFK by citrate in a high yielding and a low yielding strain of A. niger. She found that the enzyme from the low yielding strain was greatly inhibited by addition of 5.5 mm citrate, whereas the enzyme from the high yielding strain was slightly activated under the same conditions. Researchers have shown that under manganese deficiency, an accumulaton on NH+4 ions occurs in the cell during citric acid production and that condition has the effect of antagonizing the inhibition of PFK by citrate.

Citric acid formation from pyruvate

Citric acid is formed by the condensation of acetyl coenzyme A and oxaloacetic acid under the influence of citrate synthase. Normally the oxaloacetate is provided by the operation of the citric acid cycle. When citric acid accumulates, the cycle is to a greater or lesser degree blocked and another, so-called anaplerotic, reaction is needed to supply the oxaloacetate. This anplerotic reaction is the carboxylation of pyruvate by pyruvate carboxylase.

It has been shown that CO2 fixation does indeed occur and pyruvate carboxylase has been isolated from A. niger. The enzyme required no acetyl coenzyme A but was inhibited by aspartate. Since µ -ketoglutarate dehydrogenase is practically absent during citric acid accumulation aspartate concentrations must be low and inhibition minimal.

Citric synthase (Figure 39) has been studied and found that it was poorly regulated and that citric acid formation was related only to the oxaloacetic acid available. Since both citrate synthase and pyruvate carboxylase are not effectively regulated, the rate of citric acid formation is related to the speed at which carbohydrate is converted to pyruvate.

Why the normal citric acid catabolism does not occur

Citric acid is normally catabolized via and citric acid cycle. The first step in this series of reactions, conversion to a mixture of aconitic and isocitric acids, is mediated by aconitase (aconitate hydratase) (ACH). By using the high yielding strain Wisconsin 72-4 was unable to detect ACH under citric acid accumulating conditions. Additions of manganese reduced the citric acid yield and caused the appearance of ACH (there was some evidence that two aconitases were present). Scientist using a ferrocyanide treated beet molasses medium observed the disappearance of ACH during citric acid production, it did not disappear altogether. This was in contrast with citrate synthase which maintained its level almost throughout. Scientist demonstrated the activation of A. niger ACH by iron. Twenty times the optimal level doubled the ACH activity in a mutant of Wisconsin 72-4 but reduced the yield only by a factor of 0.75. The citric yields she obtained were, however, not good and her conclusions on the relation between ACH levels and citric acid production should be treated with caution. Overall, the effects of Mn and of Fe on the presence and activity of ACH accord well with experience of the fermentation.

Isocitric dehydrogenase (ICDH) and isoctric lyase (ICL) break down isocitric acid. ICL has been shown to be absent from A. niger when citric acid is accumulating. The case of ICDH is more complex, there being two enzymes with NADH and NADPH specificities. The NADH enzyme is cytoplasmic whereas the NADPH enzyme is located in the mitochondria and is inhibited by physiological concentrations of citrate. Scientist considers the possibility that the inhibition of mitochondrial ICDH by citrate causes isocitrate to accumulate and since isocitrate is in equilibrium with a much higher concentration of citrate under the influence of ACH, citrate will also accumulate. However, since only low or zero ACH activities have been detected during citric acid accumulation it is difficult to agree with this conclusion. Moreover, although there is an equilibrium between citrate, isocitrate and aconitate in the presence of ACH, isocitric acid (or aconitic acid) is not found as an impurity of citric acid made with A. niger. The situation when yeasts are used is of course very different. It is possible that the permeability of the mitochondria in A. niger in much greater for citrate than isocitrate.

Citric acid production by yeasts

Whether glucose or n-alkanes are used as substrate the fermentation pattern shows a growth phase followed by an acid accumulation phase, the transition being brought about by nitrogen limitation. When n-alkanes are used as substrate they are converted by b-oxidation to acetyl coenzyme. A which is combined with oxaloacetic acid in the usual way (Figure 39). It is thought that when glucose is used as substrate pyruvate carboxylase provides the anaplerotic reaction as in A. niger. However, when n-alkanes are the substrates, anaplerosis is provided by the glyoxylate cycle, and this is reflected by a higher level of ICL. At the same time the levels of ACH are higher than when glucose is being utilized. A problem with the yeast process is the very high ratios of isocitric acid to citric acid which are produced in some cases. These ratios are much higher than the equilibrium values mediated by ACH. It has been suggested that a selective transport of isocitric acid from the mitochondrion to the cytoplasm occurs.

PRODUCTION PROCESSES - PRODUCT RECOVERY

Removal of the fermenting organism from the final broth leaves an aqueous solution of citric acid contaminated by various organics and inorganics depending on the initial carbon source.

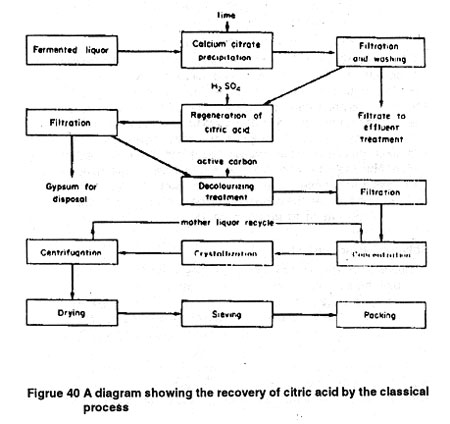

The Classical Citric Acid Recovery Process

The classical citric acid recovery process, which is particularly suitable for use with the very impure liquors derived from molasses, is to heat the fermented liquor and add lime. The insoluble calcium citrate tetrahydrate is precipitated (Figure 40). The washed precipitate is treated in aqueous suspension with H2SO4 yielding an aqueous solution of citric acid and a precipitate of by-product CaSO4 (gypsum). This set of operations has the effect of removing most of the impurities, either those derived from the substrate or those generated in the fermentation. Figure 40 shows a sequence of steps leading to packed saleable citric acid. As mentioned above, the conditions of the concentration/crystallization steps can be varied to produce either the anhydrous acid or the monohydrate.

Solvent Extration

Solvent extraction is possible alternative to the classical method but, because the available solvents tend to extract some of the impurities contained in molasses-derived liquors, it is easier to apply to the products from glucose or alkane-based substrates. The advantage of the solvent extration method is that it avoids the use of lime and H2SO4 and the concomitant problem of gypsum disposal.

Scientist proposed the use of butan-2-ol as an extractant. Later it was claimed that tributyl phosphate diluted with a minor amount of kerosene could be used. In this process a better recovery could be realized by extracting the citric acid into the solvent at a low temperature, subsequently stripping the solvent with hot water. Further details of a process of this type which can be carried out in mixer-settlers or centrifugal extractors are given.

Another variant of the solvent extraction process is the ion pair extraction system in which the extractant consists of secondary or tertiary amines having in total at least 20 carbon atoms dissolved in a water immiscible solvent. Again the extraction of the citric acid from the fer mented liquor is done at a lower temperature (£ 20ºC) and the stripping state at a higher (£ 80ºC). It is believed that this process has been licensed to Miles Laboratories Inc. Who have secured FDA approval for the use of a mixture of tridodecylamine, octyl alcohol and isoalkanes. A further development of this process is the use of N-substituted alkyl amides as extractants.

In fermentations with n-alkanes and in particular where sodium hydroxide is used for pH control, monosodium or trisodium citrate can be directly crystallized from the clarified fermented liquor. In this case citric acid may produced from the sodium citrate by electrodialysis.

EFFLUENT DISPOSAL

Reference has already been made to the production of gypsum in the calcium citrate precipitation method of citric acid recovery. The disposal of this solid waste can pose a problem. A more serious problem is the disposal of the filtrate from the calcium citrate precipitation, especially where molasses is used as the starting material. This waste, although non-toxic, has a very high oxygen demand which makes it unacceptable in rivers without treatment. Scientist have proposed the cultivation of yeasts on the effluent producing a material suitable for animal feed. Another possibility is to evaporate the effluent to produce a concentrated molasses - like material usually called condensed molasses solubles (CMS). This material can be used in feedstuff formulations. Another method of treatment is anaerobic digestion which has the advantages of producing a fuel gas as a by-product.

FUTURE DEVELOPMENTS

The current world market for citric acid (and its derivatives) is upwards of 3,00,000 tonnes per annum and it may be regarded as a mature product, although an upward trend in its usage may be expected to continue. This trend will include additional sales as an acidulent for food use as well as an increasing quantity for uses where its complexing properties are required. Its use as a biodegradable substitute for polyphosphates in detergents has not developed except in a few areas with special problems. In part this is due to price considerations. A decrease in fermentation recovery costs could change the situation, and further developments in the newer methods such as solvent extraction in its widest sense can be expected.

In the case of the fermentation stage, although most manufacturers already possess high yielding strains, scope for some further improvement probably remains, particularly in relation to the shortening of fermentation times. Mutagenic treatment of the organism followed by selection is still the normal mode of new strain development, although the selection process is made less cumbersome by use of replica plate cultures and selection pressures. Whether the methods of gene transfer will be applicable to the citric acid fermentation in the near future is doubtful. In the present state of the art, gene transfer techniques are very powerful where the desired products are single peptides or proteins.

In a 10-stage conversion such as that from glucose to citric acid, progress could only be made by identifying limiting steps and improving the flow of metabolites through these. Unfortunately, at the present time, the knowledge of the metabolic steps and of the genetics of the organisms involved is somewhat wanting in detail.

ACETIC ACID

Introduction

Vinegar, that is aqueous solutions of acetic acid used as a condiment and in picking, has been known and consumed for as long as the art of wine making has been practiced and therefore dates back to at least 10000 BC. Apparently the earliest records which refer to vinegar are the Old and New Testaments; vinegar is said to have been offered as a drink to Jesus. The Bible describes vinegar as a popular nostrum and one of the important compounds of alchemists. The word vinegar is derived from two French words, viz. vin (wine) and aigre (sour); the Latin word acetum means literally sour or sharp wine. So, it can be assumed that the first vinegar used by ancient peoples was simply spoiled wine.

Early methods obtained acetic acid from natural carbohydrates by biochemical oxidation of alcohol and destructive distillation of wood.

Vinegar may be produced from a wide variety of raw materials, e.g. apples, malt, grapes, grain, molasses, pears, peaches, oranges, whey, pineapples, and other fruits, the main requirement being a satisfactory, economic source of alcohol and accessory flavouring constituents; the term vinegar is applied to the product of acetous fermentation of ethanol from any of the above mentioned sources.

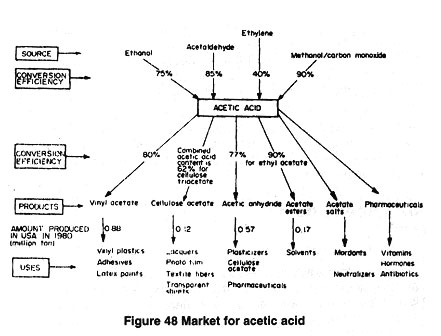

Today acetic acid is an important industrial organic chemical with approximately 2.45 million ton/year being produced and consumed world wide, half of it in the USA. It ranks 34th amongst all chemicals produced and its use is considered to be the fastest growing amongst the important of acetic acid can be understood from Figure 48 which illustrates the market for it.

Since 1950 synthetic methods have provided the major part of the world's acetic acid supply. Because it was possible for a time to hold the price of organic chemicals derived from fossil fuels within certain limits, despite a steep rise in the cost of crude oil, the need to find alternative methods of production, such as by biological routes, did not arise. The current shortfall in supply appears to be an incentive for more serious consideration of the revival of biological routes.

PRODUCTION TECHNOLOGY

Anaerobic acidogenesis

The kinetic behaviour of acidogenesis depends on the source of microflora and the type of substrate used. Very little information is available on the kinetic behaviour of acid-formers in the absence of methanogens. Most studies are known to have been carried out with the simultaneous production of methane from acids produced by acid-formers.

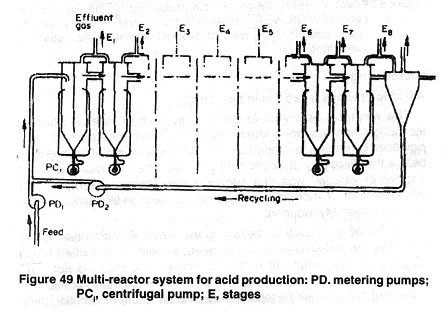

The effect of termperature, pH and initial substrate concentration on acid production and yield have been studied in a continuous multireactor system with cell recycle (Figure 49) using sucrose as substrate and inoculum isolated from a municipal sludge digester.

Control of pH at 6 results in a significant increase in acid production compared to no control of the pH system (Figure 3). The concentration of propionic acid decreases when the temperature increases and at 40ºC there is no propionic acid. Since at this temperature the toxic effect of organic acids decreases, it appears that propionic acid exercises increased toxic effects relative to acetic and butyric acids. The amount of butyric acid increases at higher temperatures.

Microbiology

Aerobic process (acetic acid bacteria)

The empirical approach to the manufacture of vinegar from an alcoholic mash has been known for a long time. Vinegar had been produced by natural fermentation in the Orleans region of France long before the discovery of acetic acid bacteria. The biological nature of 'mother of vinegar' was first suggested by Boerhaave, reported a bacterial study of 'mother of vinegar' and named the film appearing on the liquid layer 'Mycoderma'.

The acetic acid bacteria belong to the family Pseudomoadaceae. The cells are rod-shaped, but elongated, swollen or branched forms may occur. They may be motile or non-motile; they do not form endospores. The species which do not convert ethanol to acetic acid are either peritrichous flagellate (Acetobacter aceti) or non-flagellate (Acetobacter rancens). The young cells are Gramnegative in character while the older ones are Gram-positive.

EARLIER PROCESSES

The 'quick' process

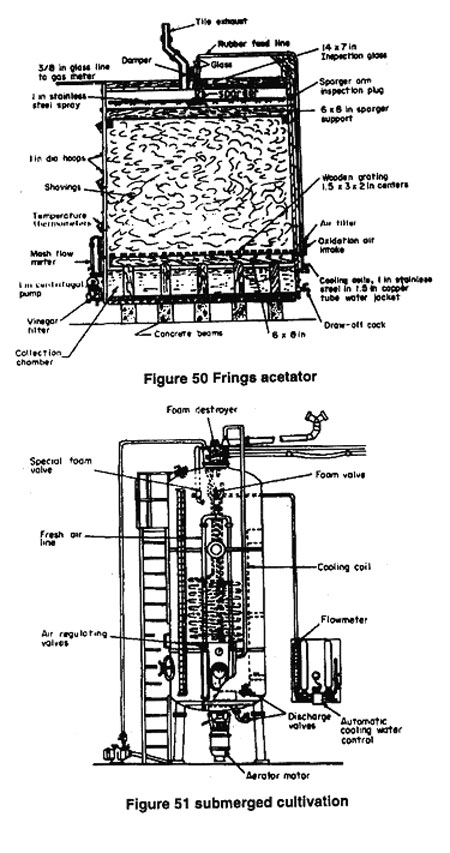

The idea that vinegar can be produced rapidly by trickling wine through packed pumice was discovered by Boerheave in the early part of the nineteenth century. It was improved by Schuzenbach to make it the 'quick process', also known as the 'German process', which is the basis for modern methods of manufacture of vinegar using a generator. The generator consists of a wooden or metal-coated tank packed with beech wood shavings on which cells are allowed to grow. The feed trickles from the top through the wood shavings. A large volume of air is sparged into the tank though perforations in the bottom. Empolying 12% (v/v) alcohol, 98% conversion into acetic acid is attained in 5 days by this process. This process has been used for the commercial production of vinegar for about a century.

Frings Process

Major improvements in the quick process took place in 1929 when forced aeration and temperature control were introduced and the trickling generator widely used today emerged. A cross-section of the Frings generator is shown in Figure 51. The significant advantages of this process include the followings :

- the cost is low, it is relatively simple and easy to control;

- higher acetic acid concentrations are obtained;

- the tank occupies less space; and

- evaporation losses are low.

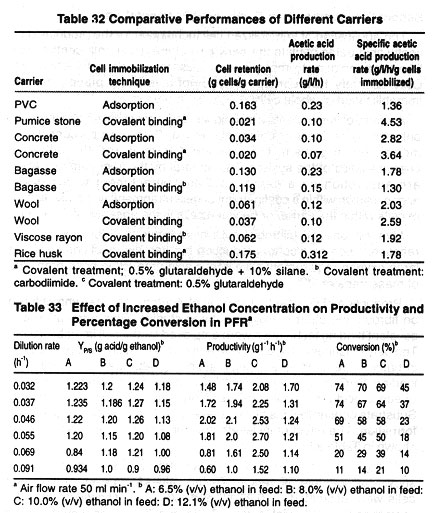

The submerged culture process

The application of submerged fermentation to the oxidation of ethanol to acetic acid was the next technical advance in the commercial production of vinegar. They noted that Acetobacter species in submerged conditions were very sensitive to oxygen deficiency and that the fermentation stopped when the level of oxygen in the gas phase was less than 5%. The success of this process depends largely on the efficiency of the aeration of the broth. The acetic acid bacteria during submerged exponential fermentation have no average oxygen uptake rate of 7.75 O2 kper gram cell per hour.

The advantages of submerged cultivation (Figure 51) over the trickling generator are : (1) the submerged cultivation permits 30 times faster oxidation of alcohol; (2) a smaller reactor volume is needed (about 16% of the trickling generator) to produce an equivalent amount of vinegar; (3) greater efficiency is achieved; yields are 5-8% higher and more than 90% of the theoretical yield is obtained; (4) the process can be highly automated; and (5) increased economy owing to the elimination of clogging by shavings, interruptions, etc. The ratio of productivity to capital investment is much higher in the case of submerged cultivation.

After the discovery of submerged acetification, a number of processes were developed, viz. (i) Yeomans cavitator (1967), in use in the US and Japan; (ii) the Bourgeois process used in Spain and Italy; and (iii) the Fardon process, used mainly in Africa for making malt vinegar. These processes were not used extensively on a commercial scale.

Recent Developments in Acetic Acid Fermentation

The application of immobilized cell techniques for the production of acetic acid dates back to the early part of the nineteenth century, but little has been done to improve the process into an efficient technology. Only recently has considerable emphasis been placed on the immobilization of whole cells.

A variety of immobilization techniques and carriers have been reported but there is no ideal or universal method. Factors to be considered include the organism, the product(s) formed and the diffusion characteristics of the system. The general methods of immobilization are adsorption on a carrier; convalent attachment to a carrier; encapsulation within a confinement or gel entrapment; and cross-linking of cells within the carrier or between cells in the absence of a carrier.

Live immobilized microbial cells have been used for multienzyme reactions such as alcohol production but aerobic reactions involving large oxygen requirements like acetic acid production pose problems of mass transfer.

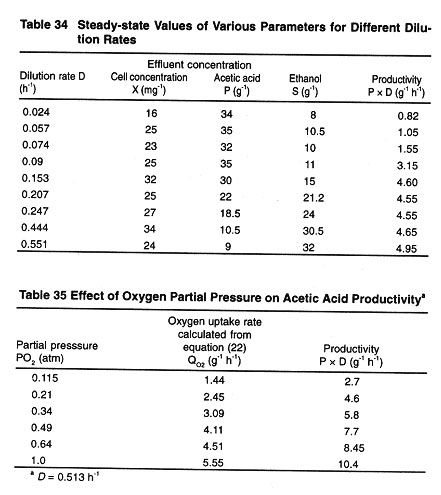

Production of vinegar by live cells of Acetobactor acetic immobilized on fibrous and other carriers has been studied. Both adsorption and covalent binding techniques were employed for the cell immobilization. The performances of the carriers in terms of cell loading and productivity in batch experiements are summarized in Table 32. In terms of cell loading, PVC, bagasse and rice husks appear to be better, but the rate of acetic acid production is higher in the case of inorganic materials. Substrate concentrations above a level of 10% are inhibitory to product formation. The effect of initial ethanol concentration on productivity is shown in Table 33.

Comparison of the growth of cells in free and immobilized states shows considerable differences. The mm values for free and immobilized cells were estimated as 0.25 h-1, respectively, and the corresponding cells yields were 0.104 and 0.008, respectively. Both oxygen uptake and carbon dioxide evolution rates are higher in free cells than in immobilized cells but the respiratory quotients for both the systems remain almost the same. According to Kennedy in the case of Acetobactor aceti immobilized on an adsorbed Ti/Zn hydroxide bed (supposedly having partial covalent binding) the oxygen consumption takes place at a rate 30% of that used by free cells. An activity decay profile of the immobilized Acetobacter follows first order kinetics and the half-life of these cells is computed as 378 h.

Recently, a modification of the tubular reactor (tower fermenter) has been applied to the acetification of alcoholic mash and a volumetric efficiency of up to 1.0 fermenter volume output per day has been achieved; this is 100% higher than the performances of the Frings process.

In a highly aerobic acetic acid fermentation, the mass transfer and two-phase flow phenomena are the dominant features of the fluidized bed tower. Generally the overall rate is limited by the rate of oxygen transfer from the air bubbles into the liquid phase. The use of a tower bioreactor reduces loss of alcohol due to evaporation. It has been reported that at an aeration rate of 0.5 vvm in a stirred tank reactor, the loss of alcohol in 48 h using 5% alcohol is nearly 28%, whereas the loss becomes about 50% at an aeration rate of 1 vvm. On the other hand in a tower fermenter very little loss due to evaporation is observed in 48 h. The loss of alcohol ultimately lowers the yield in a stirred tank by about 27% compared to a tower reactor.

According to Kennedy Acetobacter species which produce extracellular polysaccharides aggregate in the presence of hydrous titanium (IV) oxide thereby enabling a higher medium flow rate and a subsequent increased acetic acid output to be achieved. Strains of Acetobacter which cannot produce polysaccharides do not give this effect with hydrous Ti(IV) oxide but produce more acetic acid when a Ti(IV)-cellulose chelate is added to the system. The mechanism which results in a better performance by extracellular polysaccccharide-forming cells is believed to be as described below.

Water insoluble Ti compounds can react with extracellular cellulose by a cross-linking process; this encourages the formation of aggregates, thus increasing the cell density and making the cells more resistant to washout by the increased flow rate at which they form a sediment in the reacter. This gives a greater cell mass per unit volume, which leads to an increase in the rate of fermenter (2.6 1) with an aspect ratio of 8:1, the daily production of acetic acid could be increased from 87 g d-1 to 263 g d-1 by using hydrous Ti (IV) oxide in the case of aggregating bacteria; with non-aggregating bacteria, addition of a Ti (IV)-cellulose chelate produced only a 20% rise in the daily production of acetic acid

.

In the oxidative conversion of ethanol to acetic acid, delivery of oxygen from the gas phase to the bacteria can be described as occurring in three stages. First, oxygen (from air) has to dissolve in the liquid medium; the saturation concentration (9 p.p.m.) being very low, the dissolution of oxygen can obviously become limited by the rate of supply of air to the fermenter. Second, the dissolved oxygen has to diffuse through the liquid to the bacteria, and finally the oxygen has to enter the bacterium and participate in the oxidation reaction. Using Acetobacter aceti the overall mass transfer coefficient, KLa, was found to be 4200 m-1 in a pulsed reactor, the high value of KLa reflects the high oxygen transfer efficiency of the pulsed flow, also observed.

Researchers studied the performance of a pulsed reactor using cylindrical monoliths of cordierite, a porous ceramic which has good mechanical properties and is chemically inert. Cell adsorption was irreversible and followed first-order kinetics, maximum cell loading was 2.6 mg g-1 of cordierite. The effect of dilution rate on product formation in this system in Table 34. At low D ([0.1 h-1), even in the presence of residual alcohol, the acetic acid concentration is almost constant (30-35 g-1); this is attributed to the inhibitory effects of acetic acid. At high dilution rates the acetic acid production may be limited by the partial pressure of oxygen. Using pure oxygen a maximum productivity of 10.4 g-1 h-1 was observed which is about 2.3 times that obtained using air in the pulsed reactor system (Table 35).[/P]

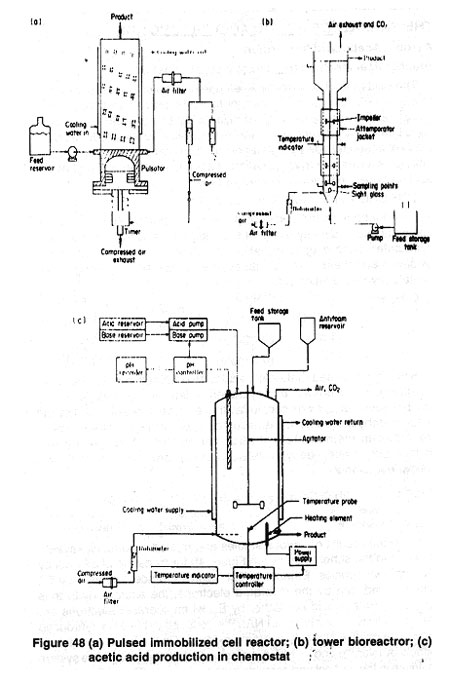

Diagrams of a pulsed immobilized reactor, a tower reactor and chemo stat cultivation are presented in Figure 4.

THE BIOLOGY OF ACETIC ACID PRODUCTION

Aerobic Acetic acid fermentation

Biochemical mechanism of acetic acid formation

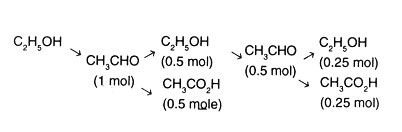

This oxidation of ethanol by Acetobacter is a two-step process: the first is a partial oxidation of ethanol to acetaldehyde and the second completes the oxidation of acetaldehyde to acetic acid. Under anaerobic conditions 1 mol of each of ethanol and acetic acid. Under anaerobic conditions 1 mol of each of ethanol and acetic acid are produced from 2 mol of acetaldehyde by the Cannizaro dismutation reaction; 1 mol of ethanol is formed by hydrogenation of acetaldehyde and one of acetic acid by oxidation of acetaldehyde equation 1.

2CH3CHO + H2O ] C2H5OH + CH3CO2H

Researchers postulated that under aerobic conditions 1 mol of acetaldehyde is directly oxidized to acetic acid and the other mole is dismutated according to equation (1). With adequate aeration the oxidation and the dismutation proceed side by side converting all the acetaldehyde to acetic acid :

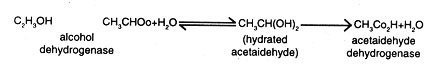

Since it is reported that acetic acid is also formed in the absence of oxygen but in the presence of hydrogen acceptors like methylene blue and benzoquinone, it was concluded that acetic acid was formed by the action of dehydrogenases. It is assumed that hydrated acetaldehyde is formed as an intermediate. In the first step alcohol dehydrogenase and in the second acetaldehyde dehydrogenase are involved as shown below : equation 2.

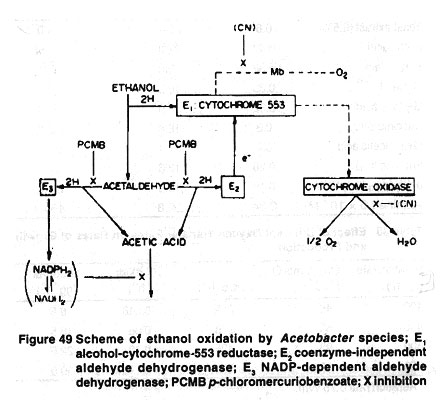

From the results of various studies and related reports, Nakayama postulated the scheme shown in Figure 49 for oxidation of ethanol by Acetobacter species. Ethanol is first oxidized to acetaldehyde by E1, which is reduced by the libterated electrons; the acetaldehyde thus formed is further oxidized either by E2, when liberated electrons are delivered to E1, or by E3 when NADP is reduced to NADPH2. Reduced E1 is then oxidized by a cytrochrome oxidase. On the basis of inhibition effects by cyanide and PCMB, it is presumed that the cytochrome system is driven in the ethanol and acetaldehyde oxidation by E1 and E2, whereas the NADPH2, produced by E3 inhibits further oxidation of acetic acid through the TCA cycle by changing the equilibrium NADPH2 ] NADH2.

The Role of Metabolites

The important of the addition of yeast extract to the medium with regard to higher ethanol tolerance and higher productivity has already been discussed. It has another important effect, viz. shortening of the lag phase in acetic acid fermentation. Lactic acid, pyruvic acid, glycerol, glycenic acid, a-glycerophosphate, alanine, succinic acid and furmaric acid are reported to exercise such effects; decreased lag effect is accompanied by an increase in the ratio of acid produced to cell growth (Table 5.) implying that the flow of metabolism in cells is changed in favour of acetic acid production rather than cell growth.

Tetracocus soyae, a homofermentative lactic acid bacterium, can utilize glycerol as an energy source only under aerobic conditions and both growing and resting cells produce acetic acid as the end product from glycerol. The acid yield is about 70% and its concentration reaches 12 g-1. Glycerol can be completely dissimilated to acetic acid; lactic acid is produced initially but it readily undergoes oxidative degradation to acetic acid. Glycerol dissmilation is catalyzed by inducible enzymes and cells posses high levels of catalase and cytrochromes. H2O2 produced in the oxidation of L-glycerol 3-phosphate is decomposed by catalase.

The effect of oxygen

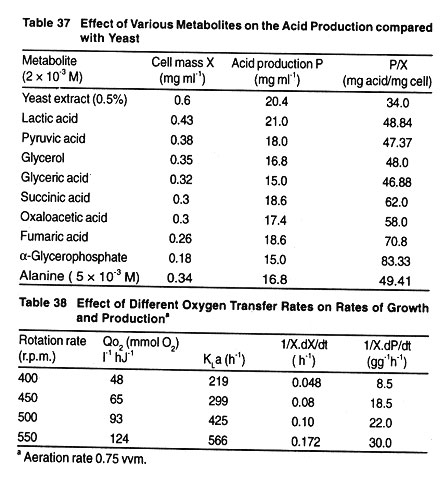

It has long been recognized that oxidative microbial production of acetic acid is a highly aerobic process. Values of oxygen transfer coefficients for Acetobacter aceti are presented in Table 38.

Anaerobic Conversion

Microbiology

The mixed flora popularly known as acid-formers, which are responsible for the conversion of cellulose to volatile fatty acids, comprise two distinct of bacterial species : celluloytic and non-cellulolytic. The interaction between these two groups in acidgenesis is very complex. Biosynthesis and extracellular cellulase activities are constrained by non-celluloytic organism provide some nutritional inputs such as vitamins, growth factors and branched chain fatty acids necessary for celluloytic species.

The first step in acidogenesis is the solubilization of cellulose and hemicellulose. The most active celluloytic species have been shown to be Gram-negative, short rods (Bacteroides sp.) and cocci. The anaerobic cellulase activity of Ruminococcus is partially inhibit enzyme activity but their effect on cellulose biosynthesis is not yet resolved.

In spite of their critical role, celluloytic bacteria constitute a small fraction of the total acid formers and the distribution of population depends on the type of waste on which they grow. Formic, acetic, butyric, propionic, lactic, succinic and isobutyric acids are produced from the degration of cellulose.

Biochemical mechanisms

The primary metabolic products of celluloytic bacteria include aliphatic acids (formic, acetic, propionic, butyric, valeric), lactic acid, succinic acid, ethanol, carbon dioxide and hydrogen.

Cl. thermocellum ferments glucose and fructose almost stoichiometrially to acetate according to the following steps :

C6H12O6 + H2O ] CH3COCO2H + CH3CO2H + CO2 + 6 H

CH3COCO2 +CO2 + 6 H ] 2 CH3CO2H + H2O

Overall reaction : C6H12O6 ] 3 CH3CO2H

In the first reaction the hexose is fermented via the fructose diphosphate pathway to 2 mol of pyruvate of which one is further metabolized pathway to 2 mol of pyruvate of which one is further metabolized to acetate and carbon dioxide; six equivalents of electrons are formed during this process. In the second step, these electrons are used to reduced carbon dioxide to the methyl group which yield 2 mol of acetate in a transcarboxylation reaction involving the carboxyl group of pyruvate formed in the first step.

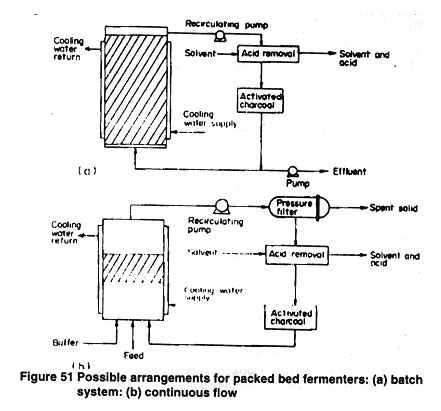

Dynatech workers have successfully fermented aquatic weeds to produce organic acids inhigh yield in a fixed packed bed bioreactor shows batch and continuous fixed bed bioreactors for the production of acid. The liquid is circulated through the loop of the packed bed. Toxic compounds may be removed from the aqueous phase by passing through an activated charcoal cleaner. The acid is removed in an external subsystem by solvent extraction. Fixed packed bed fermenters can improve operating parameters and can remove a number of constraints, like mass transfer, generally faced in conventional digestion systems. Sodium hydroxide pretreatment to increase biodegradability of lignocellulosics by ruminants is well known.

Recovery and Purification

The separation of acetic acid from water has been industrially important for many years. The physical methods which have been considered include : (i) fractional distillation; (ii) azeotropic dehydration distillation; (iii) solvent extration; (iv) combination of the above methods; (v) extractive distillation; and (vi) carbon adsorption.

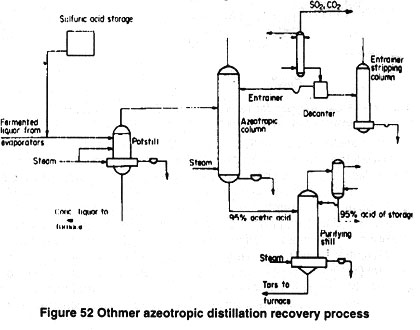

As an alternative, to reduce energy consumption azeotropic dehydration, can be employed. In this method a water insoluble 'withdrawing' liquid called the entrainer is added, which decreases the effective boiling point of water relative to that of acetic acid by the formation of a low boiling point azeotrope. Low molecular weight esters such as butyl acetate are generally used as entrainers. A flow diagram of azeotropic distillation is shown in Figure 52.

For intermediate concentrations (10 to 50%), liquid-liquid extration is employed and usually is followed by azeotropic distillation. Low molecular weight solvents (esters, ethers and ketones) have sufficiently high distribution coefficients for acetic acid at low concentrations. Ethyl acetate along with diethyl ether are still considerated to be most efficient extrations.

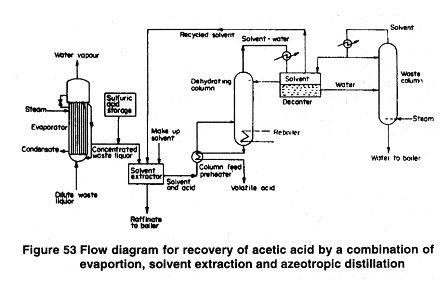

Scientist suggested a combination of extration, azeotropic distillation and possibly extractive distillation for the production Scientist of glacial acetic acid. Amberg modified this proposition and recommended the following steps for the recovery of volatile fatty acids from fermentation liquors : (i) evaporation of the fermented liquor to 40-50% solids, (ii) solvent extraction using methyethyether as solvent; (iii) dehydration and recovery of solvent by azeotropic distillation; and (v) refining 95% acetic acid to the glacial state. A schematic diagram is shown in Figure 53.

An economically attractive scheme for the recovery of acetic acid from a dilute aqueous stream by extraction with a hydrocarbon followed by distillation has been developed by Helsel. The extractant used is a high boiling (bp 460ºC) trioctylphosphine oxide (TOPO). It is soluble in many polar and non-polar solvents but has a very low water solubility (1 p.p.m.). The four operations of the system are shown in Figure. The inherent advantages of this new technology are : (i) a high distribution coefficient of acetic acid in very dilute aqueous solution allows a small solvent (TOPO) volume to be used; (ii) good phase separation reduces the size of the extration equipment; (iii) the stability and high boiling point of the solvent enable a small volume of acid to be recovered from a much larger solvent flow; and (iv)the low solubility of the solvent in water permits higher selectivity of the solvent and obviates the need for raffinate stripping. These advantages represent significant energy and capital savings compred with other recovery processes, especially when the acetic acid concentration is less than 5%. For 2% acetic acid solution the energy required for recovery is about 15 GJ/ton of glacial acetic acid.

To avoid product inhibition in the reactor, a concurrent extration process is required which will remove acetic acid continuously to keep its level below the critical point in the fermenter. The extraction methods suggested are ion-exchange resins, solvent extraction and membrane separation.

The oxidized organic impurities are removed with the solvent layer while the MnO4 stays in the water layer and can be reused.

Comments

The yield of acid can be increased in both aerobic and anaerobic process by control of pH, temperature and residence time. In the case of an aerobic process, the most critical parameter is oxygenation, so that should be controlled very carefully parameter is oxygenation, so that should be controlled very carefully, and loss of ethanol due to evaporation should be minimized. In acidogenesis, the main problem lies with the methanogens that are associated with the acid-formers in the mixed culture. When acids are the desired products, any conversion of acid to methane and carbon dioxide is a loss, so methanogens grow much more slowly than acid-formers, these are gradually outnumbered by the acid-formers. Use of this enriched culture of acid-formers in the digester at pH[6 stops subsequent conversion of acid to methane. The washout of methanogens is achieved by controlling the dilution rate in a continuous system. A. D. value above 0.3 d-1 excludes methanogens from the reactor.[/P]

Another bottleneck in acidogenesis is the low acid tolerance of acid-formers. This can be improved by injecting acid into the reactor to adapt the crude culture to higher acid concentrations. It has been found that addition of acetic acid at a level of 0.2% increases release by 30%.

ENERGY ANALYSIS OF ACETIC ACID PRODUCTION

One of the earliest methods for preparing acetic acid was by destructive distillation of wood to give pyroligneous acid, which contained 10% acetic acid. The acid used to be recovered by solvent extraction and distillation. This method was later replaced by a synthetic chemical process in which energy requirement is about 45% of that required in the wood distillation process.

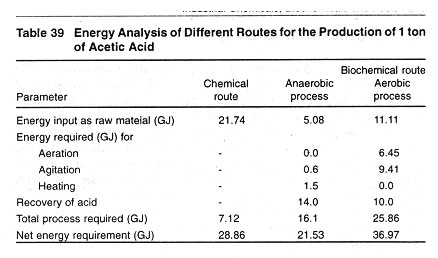

The energy requirements for the production of acetic acid by the following routes can be compared : (i) the chemical route (from acetylene); and (ii) the biochemical route via (a) the aerobic process, (b) the anaerobic process.

Chemical Route

C2H2 ] (H2O) ] CH3CHO ] (0.5 O2) ] CH3CO2H

26 tons acetylene produce 60 tons acetic acid. The energy diagram for the production of 1 ton of acetic acid is shown below.

0.433t acetylene/21.7 4w ] Chemical Process ] acetic acid

Chemical Process [ Energy required For the process = 7.12 GJ[/P]

Aerobic Process

Basis 1 ton of acetic acid; 10% acetic acid is produced in the broth. The energy content of the raw material is calculated on the basis of the net energy available by incineration. For this, the following basis has been taken (Alfa-Laval; steam at 4 bar):

Energy required for evaporation tons steam in five-stage evaporator (i.e. to bring the slurry up to 60% TS) tons water evaporated = 0.227 = tons steam/tons water evaporated

Energy obtained by combustion tons steam generated of concentrated slurry (60% TS) = 3.85 = tons steam generated/tons of dry solid

Although the raw material has a calorific value of 23.55 GJ, the net energy available through incineration is 11.11 GJ. The temperature of fermentation is about 30º C, so the energy required for heating can be neglected. The results are summarized in Table 39.

Since a higher acetic acid concentration is obtained in the aerobic system than in the anaerobic process, the energy required for the acid recovery is less.

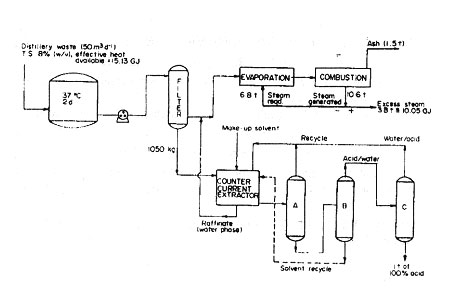

Anaerobic acidogenesis

Distillery waste has been found to produce acetic acid anaerobically in an appreciable quantity in a very short time (2 days). Basis of calculation : 1 ton acetic acid; distillery waste containing 8% TS (BOD 45000 p.p.m.). In this case no energy is required for aeration but acid concentration is low (about 2%), so much energy is required for separation. The energy requirements for heating, recovery of acid, etc. are shown in Table. Schematic diagram of anaerobic acid production and separation is shown in Figure 54.

Lactic Acid

Lactic Acid (2-hydroxypropanoic acid, 2-hydroxypropionic acid) is an organic hydroxy acid whose occurrence in nature is widesperead.

PHYSICAL AND CHEMICAL PROPERTIES

Lactic acid first isolated from sour milk. The chemical and physical properties of latic acid have been extensively reviewed. Lactic acid exists in two optically isomeric forms shown (1) and (2) see Table 45.

Table 45 : Physical Properties of Lactic Acid

| Molecular weight |

90.08 |

| Melting point D (-) or L (+) |

52.8-54ºC |

| |

DL (Varies with composition) |

16.8-33ºC |

| Boling point DL |

82ºC at 0.5 mmHg |

| |

122ºC at 14 mmHg |

| Dissociation constant (Ka at 25ºC) |

1.37 Ã- 10-4 |

| Heat of combustion (D Hc) |

136 1kJ mol-1 |

| Specific heat (Cp at 20º C) |

190 Jmol-1 ºC-1 |

PRODUCTION TECHNOLOGY

Microorganisms and Raw Material

Microorganisms

The homofermentative lactic acid bacteria catabolize 'glucose via the Embden-Meyerhof pathway. Two lactic acid molecules are produced from each molecule of glucose, typically with a yield of better than 90 g per 100 g glucose. Pentose sugars are also metabolized by some homofermentative species sterospecific and lactic acid are the products of this metabolism. Organisms may produce D (-).., L (+).. or DL-lactic acid. The formation of the racemase. The classification of many strains of lactic acid bacteria is still in much confusion at the present. Consequently, it is best to consult the literature on a specific strain or perform an analysis to determine the sterospecificity of the lactic acid it produces. The lactic acid bacteria are extremely limited in their synthetic capabilities. They always require B vitamins and almost without exception require a large number of amino acids.

The selection of an organism depends primarily on the carbohydrate to be fermented. L. bulgaricus, L. casei or S. lactis are used to ferment Lactose. Adapted strain of L.delbrecki and L. leichmanni are typically used to ferment glucose. L. pentosus has been used to ferment sulfite waste liquor. Researchers have isolated a homofermentative strain called L. amylophislus which is capable of fermenting starch to L(+)- lactic acid with 90 wt% yields. Mixtures of strains as well as pure cultures have been used for the commercial manufacture of lactic acid.

Some fungi of the species Rhizopus Particularly R. oryzae, can be used to produce L(+)-latic acid. This organism has less complex nutritional requirements than the lactic acid bacteria. Yields and fermentation rates of glucose are comparable to those of Lactobacilli. Rhizopus species can also utilize starch feedstocks. The process, however, never achieved lasting commercial success. The use of organisms such as Rhizopus with less exacting nutritional requirements could possibly the feed costs and simplify the recovery process.

Raw Materials

A large number of carbohydrate materials have been used, tested or proposed for the manufacture of lactic acid fermentation. It is useful to compare feedstocks on the basis of the following desirable quantities: (1) low cost, (2) low levels of contaminants, (3) fast fermentation rate, (4) high lactic acid yields, (5) little or no by-product formation, (6) ability to be fermented with little or no pretreatment, and (7) year-round availability. Crude feedstocks have historically been avoided because high levels of extraneous materials can cause troublesome separation problems in the recovery stage. Use of pentose sugars results in the production of acetic acid which will incur extra process equipment for separation and could potentially become a nuisance from a marketing standpoint.

Sucrose from cane and beet sugar, whey containing lactose, and maltose and dextrose from hydrolyzed starch are presently used commercially. Refined sucrose, although expensive, is the most commonly used substrate, followed by dextrose. Not surprinsingly, some lactic acid manufactures are connected with the beet or cane sugar business. Dextrose from corn starch was most commonly used feedstock. Concentrated whey has been used without any other pretreatment. Cellulosic materials such as corn cobs, corn stalks, cottonseed hulls, and straw and sulfite waste liquor have been used. Acetic acid is produced as a by-product from cellulose derived sugars.

Fermentation process

Batch fermentation has been the method used industrially. Fermenters have been constructed of wood or 316 stainless steel, and equipped with heat transfer coils for temperature control. Minimal agitation is provided by top or side mounted stirrers in order to keep the contents mixed. Fermenters are typically steam heated with water for boiling or chemically sterilized before filling with a pasteurized medium. Often, fermenter covers as loose fitting. Contamination is not a large problem: the most serious contamination problems are due to the growth of butyric acid bacteria at the end of the fermentation. Final product concentrations are due to growth of butyric acid bacteria at the end of the fermenation. Final product concentrations are less than 12-15% depending on the other fermentation conditions to prevent precipitation of calcium lactate.

Fermentation conditions are different for each industrial producer but are typically in the range of 45-60º C with a pH of 5.0-6.5 for L delbreuki 42ºC and a pH of 6-7 for L. bulgaricus, and 30-50ºC and a pH below 6 for Rhizopus. The inoculum size is usually 5-10% of the liquid volume the fermenter. The inoculum can be propagated in seed tanks or taken from a completed large scale fermentation. The acid formed is neutralized by calcium hydroxide or calcium carbonate. The neutralizing agent can be added in excess as a slurry at the beginning of the fermentation or added intermittently during the fermentation on the basis of pH or acid titration measurements. The fermentation time is 1-2 days for a 5% sugar source such as whey and 2-6 days for a 15% sugar source such as glucose or surose. Reactor productivities are in the range of 1-3 kgm-3 h-1. Under optimal laboratory condition the fermentation takes one or two days. The yield of lactic acid after the fermentation stage 90-95 wt% based on the initial sugar or starch concentration. The residual sugar concentration is typically less than 0.1%. Cell mass yields can be as large as 30 wt% but generally are less than 15 wt% based on the initial sugar concentration. The yield of cell mass depends heavily on the amount of nitrogenous nutrients used. The fermentation rate depends primarily on the temperature, pH, concentration of nitrogenous nutrients, and the lactic acid concentration. A controlled pH batch fermentation will proceed quickly at first. Minimum cell mass doubling times are about one hour, but these rates are not achieved under industrial operating conditions where the amounts of nitrogenous nutrients are suboptimal.

Recovery Processes

Lactic acid is sold in three major grades : technical, food (FCC) and pharmaceutical (USP). The grades are listed in order of increasing purity and more elaborate recovery processes are needed to produce the higher quality material. In addition, heat stable lactic acid, which does not discolour significantly upon heating to about 200ºC for a few hours, has a large market. The recovery of lactic acid or lactate salt from the fermentation broth is a large part of the total cost of manufacture. Synthetically made lactic acid may be purified with less effort and thus in the past has been preferred for uses where heat stability is needed.

Materials of construction for fermentation and recovery equipment are limited by the very corrosive nature of lactic acid, and contribute significantly to the products final cost. Iron, copper, copper alloys, steel, chrome steel and nomal are unsatisfactory. Inconel and nickel are better but not recommended. Low iron alloys with large amounts of nickel and chromium corrode at an even slower rate. High molybdenum stainless steels such as 316 SS are satisfactory but still encounter problems, especially at improperly annealed welds and at gas/liquid interfaces where oxygen is present. Silver and tantalum are suitable, but too expensive for general use. In addition to equipment failure, corrosion increases the number of metal ions in the product which must be removed for some end uses. Wood, especially cyress and pitch pine, are satisfactory for dilute solutions but become dried out when exposed to concentrated solutions. Rubber is suitable for low temperature applications. Glass and ceramics are resistant, but their brittleness and poor heat transfer properties limit their usefulness. Some plastics are softened by warm concentrated lactic acid; however, heresite-lined, saran-lined, Teflon-lined and polyester materials have been used. Plasticizer and other additives in plastic acid; however, heresite-lined, saran-lined, teflon-lined and polyester materials have been used. Plasticizer and other additives in plastic and rubber materials may be extracted or decomposed by lactic acid under some conditions. Advances in plastic, rubber ceramic, composite materials and metal alloys may provide some new materials choices with more attractive cost and acid resistance.

The first step in all recovery processes is to raise the fermentation liquor's temperature to 80-100ºC and increase the pH to 10 or 11. This procedure kills the organisms, coagulates the proteins, solubilizes the calcium lactate, and organisms, coagulates the proteins, solubilizes the calcium lactate, and degrades some of the residual sugars, the liquid is then decanted of filtered. For some purpose, acidification of this liquor yields a usable product; however, for most applications further processing by one of the following methods is required. It should also be noted that use of cheap but impure raw materials must be weighed against higher purification costs.

Filtration, carbon treatment and evaporation

One of the methods for commercially producing lactic acid relies on the fermentation of relatively pure sugars with minimal amounts of nitrogenous nutrients. Thus, by using a pure feedstock the recovery process is simplified. Figure 60 shows the process that was used by process is simplified. Figure shows the process that was used by the American Maize-Products Co. to produce lactic acid from glucose. The process may be used to produce technical or food grade acid. After the fermenter broth is filtered, activated vegetable carbon is used to bleach the calcium lactate for production of food grade acid. No carbon treatment is used for the technical grade. Next, the calcium lactate is evaporated to a 37% concentration at 70ºC and 0.57 atm. The concentrated lactate is then acidified with 63% sulfuric acid, and the calcium sulphate precipitate is removed by a continuous filter and sent back to the first filter which treats the fermenter liquor. The filtered acid is then treated with activated carbon from the filter cakes of the first, third and fourth carbon treatments. The carbon from this step is discarded. The lactic acid is then evaporated from 8 to 52% or 82% in 316 stainless steel evaporators. Technical grade acid is then diluted to 50% or 80% and treated with sodium sulfide to remove heavy metals if needed. Edible grade acid is diluted to 50 or 80%, bleached with activated carbon for a third time, and treatment with sodium sulfide to remove heavy metals. It is then bleached a fourth time with carbon before packaging. Other manufacturers have used fewer carbon treatments. Heavy metals could be removed by ion exchange which may also remove some of the amino acids present. Heavy metals can also be removed by the stoichiometric addition of calcium or sodium ferrocyanide to form insoluble ferrocyanide salts of the heavy metals. Whether or not this process is presently used is not widely known.

Calcium lactate crystallization

Lactic acid may be recovered from fermentations utilizing cruder raw materials such as whey or molasses. Several grades of calcium lactate and lactic acid were produced from whey. The filtered liquor from the fermenters was treated with carbon first under slightly alkaline and then under slightly acidic conditions. The crude calcium lactate liquor was then evaporated under vacuum to a density of about 1.12 kg m-3. Technical grade acid was made from this liquor after evaporation, acidification, filteration of the precipitated calcium sulfate, carbon treatment and heavy precipitation. To make higher grades of product the liquor was cooled, crystallized and washed. The mother liquor and wash water were also cooled, crystallized and washed. The crystals were redissolved and similarly recrystallized as in earlier steps to create purer grades. Acids of different purity were made from the different grades of crystals by dissolution in water, acidification, calcium sulfate precipation filteration, evaporation, carbon treatment and heavy metals precipitation. Sheffield is currently making unit and a strainless steel double effect evaporator is used. Impurities are removed by filtration and carbon treatments. The hydration of the final product is controlled in the drying stage.

Peckham describes a process for the purification of the lactic acid by calcium lactate precipitation. The fermenter liquor is filtered and evaporated to 25% lactic acid. The calcium lactate is then crystallized and separated from the mother liquor. The mother liquor can be used for technical acid. The crystals are made into acid by a series of treatments similar to those used by by Sheffield Products Co.

These methods provide a product that is low is unfermented carbohydrates but may contain some ash which is mainly calcium sulfate. The crystals tend to form clusters and can be difficult to wash. The wash water and mother liquor contain high amounts of calcium lactate due to its high solubility, and must be recycled. Important costs in the purification process are related to the energy for water removal, losses in yield, and labor.

Liquid - Liquid extration

The extration of lactic acid in to an immiscible solvent phase has been researched by many investigations. Lactic acid can be purified in this way from fermentations using crude raw materials. In all such processes the acid must first be extracted from the crude liquor by the solvent, and then recovered from the solvent by some means such as back extraction into water or distillation of the solvent-lactic acid mixture.

The extraction solvent should have a low water solubility, a high distribution coefficient for lactic acid, and a low distribution coefficient for impurities such as the residual sugars. Scientist discusses some other desirable solvent properties. The distribution coefficient is defined as the concentration of lactic acid in the solvent phase divided by the concentration of lactic acid in the water phase. Extraction data for solvents with lactic acid and water and some data for solvents with crude lactic acid fermentation liquors are given. The effect of adding inorganic salts to the aqueous phase and the distribution coefficients of sucrose and lactose with several solvents was examined, who advocated the use of isopentyl alcohol as a solvent. They included a flow sheet for their proposed process in which the lactic acid is recovered from the solvent by steam stripping.

Croda Chemicals Ltd. has used a countercurrent extraction with isopropyl ether as the solvent. A description and blocky flow diagram of the process was published when the operation began. The fermentation liquor is filtered and then acidified with sulphuric acid; the calcium sulphate is filtered off. Next, the crude lactic acid is decolorized with activated carbon and then heavy metals, calcium and amino acids are removed by ion exchange. The acid is then evaporated under vaccum before it enters the countercurrent extraction columns. The acid is recovered from the solvent by countercurrent extration into water. Next, the acid is given additional activated carbon and ion exchange treatments as needed. Lastly, the acid is evaporated to its final concentration. The solubility of isopropyl ether in water is low and the loss of solvent is tolerable. Croda presently uses the same process expect that another solvent may now be used.

Lactic acid refined by liquid - liquid extraction is substantially free from ash, but contains other impurities from the raw materials and needs additional treatment by activated carbon, oxidation and other means.

Distillation of lactate esters

High quality lactic acid, substantially free from residual sugars and other impurities, can be prepared by the esterification of lactic acid with a low molecular weight alcohol, distillation of the lactic ester, hydrolysis of the distilled lactate ester to yield the alcohol and lactic acid, and distillation of the alcohol from the regenerated lactic acid. A process involving methyl lactate was proposed by Hillringhaus and Helium is 1905 and by Byk in 1912. Sulfuric acid was used to catalyze the reaction in any excess of menthanol. An overall yield of 85% was reported. Filachione and Costello give details for a procedure to make lactic acid esters directly from ammonium lactate which is the crude fermentation product if ammonia or one of its salts is used to neutralize the acid during the fermentation. Schopmeyer discusses the operation of a commercial unit that was used to continuosly refine lactic acid by the distillation of methyl lactate. The product obtained was ash free and low in all other impurities. Corrosion of the stainless steel columns contaminated the product with iron. Ceramic equipment was found to be unsuitable because of frequent temperature changes and the strong acid. Problems were also encountered with gasket materials.

Synthetic Manufacture

The synthetic manufacture of lactic acid on a commercial scale began around 1963. Today these two countries produce roughly 50% of the world's lactic acid. Synthetic lactic acid production is based on the hydrolysis of lactonitcle by a strong acid such as HCI:

MeCH(OH) CN + 2H2O + HCI ] MeCH(OH)CO2H + NH4Cl

An ammonium salt is formed as a by-product of this reaction. Lactonitrile was obtained along with acetaldehyde as a by-product of acetylene based acrylonitrile synthesis, but it is presently made from hydrogen cyanide and acetaldehyde :

HCN + MeCHO ] MeCHO(OH)CN

Hydrogen cyanide may be obtained as a by-product from the propylene ammoxidation route to acrylonitrile, or from the reaction of ammonia and light hydrocarbons such as methane. Synthetic lactic acid made substantial gains when it was introduced to the market place because more importantly, the production of stearoyl-2-lactylates required a high purity, heat-stable lactic acid. The synthetic lactic acid contains no residual sugars and does not discolour significantly upon heating. Although by-products were used in synthetic manufacture in the past, lactic acid in now made starting from actaldehyde and hydrogen cyanide. Monsanto (USA) starts from actetaldehyde and hydrogen cyanide, whereas Mushashino (Japan) purchases the lactonitrile from another manufacturer.

The lactic acid is purified by forming methyl lactate, distilling the ester, and then hydrolyzing the methyl lactate, Methanol, hydrogen cyanide and other impurities are removed by a combination of steaming, carbon treatment and ion exchange. The acid can also be recovered by solvent extration.