OIL OF LEMON

History. - The origin of the lemon, Citrus limon (Linn.) Burm. f., has been a mystery, although there exists some indication that it is a native of southeastern China, where it was known and cultivated before the Sung dynasty. Geographical distribution, as well as the names applied to the fruit, point toward the Eastern Himalayas as the home of the lemon. It may ultimately, however, prove to be a hybrid, or sport, of the so-called lemon of India. The lemon might also have the citron (Citrus medica Linnaeus) and the lime (Citrus aurantifolia Swingle) for parent species, being a hybrid of these two; or it might be considered as a satellite species of the citron.

Whatever its origin, it appears quite certain that the lemon, like the sour orange, was unknown to the Romans, despite the vast extent of their empire and its wide flung commercial relations with Asia Minor, Persia, and even India. Apparently the lemon was introduced to Persia and Palestine at the beginning of the twelfth century A.D., as it was then commonly grown in those countries and is described in many Arabian works of that period. In the following decades the lemon was brought to northern Africa, Spain and Sicily, probably by the Crusaders, who followed the activities of the Arabs in spreading citrus culture.

As a result of this development, Sicily and Calabria, in southern Italy, became the leading lemon producing regions of the world, although the refinement of the industry has taken place chiefly in California.

California Lemon Oil

Introduction. - California is the only state in the Union in which lemons are grown successfully and on a large scale. Climatic and soil conditions in California are much more suitable to lemon cultivation than they are, for example, in Florida, the lemon preferring a somewhat drier climate and being easily attacked by all kinds of fungus diseases and rots, so prevalent in a hot and humid climate.

Varieties of California Lemons. - Two varieties of lemon are cultivated in California. The more extensively grown Eureka was originated in 1877 by T.A. Garey, as a selection from several trees grown from seeds of Sicilian lemons. The Lisbon lemon was introduced into California in 1874 or 1875, as a budded tree from Australia. The Eureka is a late spring and summer variety, while the Lisbon bears fruit in winter and earlier spring. The Lisbon tree seems to be more vigorous and hardy, as its denser foliage enables it to resist light frost, wind, and sunburn to a greater degree. The fruit of the Eureka and Lisbon differ somewhat in shape, but in both varieties there is such latitude in this respect that even an expert cannot always distinguish the two.

Methods of Expressing the Oil. - California lemon oil is today expressed by the same processes and in the same type of machines as those used in the extraction of orange oil. They have been discussed at length in the section on “Modern, Large-Scale Citrus Juice and Oil-Pressing Equipment.â€

Yield of Oil. - On complete exhaustion by steam distillation the peel from 1 ton of lemon fruit will yield about 14 lb. of distilled oil. Coidpressing yields much less oil, the average being only 6-7 lb. of oil per ton of fruit. As in the case of orange or grapefruit oil, a good deal of the oil will be retained by the sponge-like albedo of the peel. In general, however, lemon peel yields its oil somewhat more readily than orange peel, because the latter is softer, more spongy, and puffy. Obviously, the yield of lemon oil depends upon a good many factors, such as condition and maturity of the fruit, the method of expression, the type of oil press used, etc.

Differences in the Quality of California Lemon Oil According to Region. - The quality of California lemon oil depends upon the region in which the fruit is grown, lemons from the foothills yielding oils of an odour and flavour somewhat different from those grown in coastal plains. To assure the supply of a uniform oil, therefore. Exchange Lemon Products Company, California Fruit Growers Exchange, in Corona, California, blend the two types of oil before marketing the well-known Exchange brand of lemon oil.

Physicochemical Properties of California Lemon Oil. - A thorough study on the physicochemical properties and composition of expressed California lemon oil was made by Poore, who examined seventy-three samples of oil from lemons grown in seven counties of California. Poore determined the ester content as linalyl acetate according to the Seeker-Kirby method, whereby the aldehydes are first eliminated with hydroxylamine hydrochloride so that alkali is consumed only for the saponification of esters, and not for the decomposition of aldehydes in addition. For the determination of citral, Poore employed the phenylyydrazine method of Kleber, which is discarded today in favor of more accurate hydrbxylamine method, because Kleberâ€TMs method gives too high values.

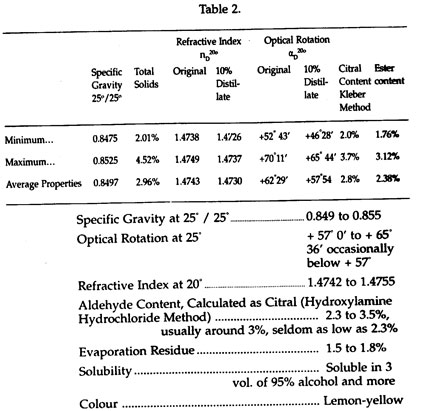

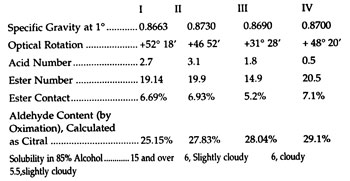

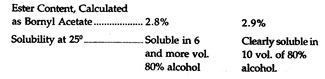

Poone found that his samples of expressed California lemon oil possessed the properties shown in Table 2.

Poore also studied the properties of California lemon oils produced in the various districts. He came to the conclusion that the averages of results by counties show a noticeable variance only in the lower optical rotation and higher percentage of citral from Ventura and Santa Barbara counties, which join one another. The highest average optical rotation was found in Riverside County and the next highest, in Los Angeles County. Otherwise the averages were fairly uniform. In optical rotation and citral content the difference between the maximum and minimum of all samples was large, the difference in optical rotation being 17° 28' and the difference in percentage of citral (Kleber method) being 1.7.

The average is quite uniform, also, if commercial shipments of California Fruit Growers Exchange lemon oil are compared. This company has, made it its policy to supply as uniform qualities as possible. Much emphasis is placed upon uniformity of flavour; but the properties, too, remain quite uniform throughout the years. This is possible only because enormous quantities of fruit originating from many counties and districts are worked up in one central factory, and large quantities of oils are bulked before shipping. Conditions in Italy are different not only because there is a marked difference in the oils produced in various sections of Sicily (in fact, by their characteristic properties Sicilian oils can often be recognized as originating from certain localities), but also because Sicilian oils are produced by numerous small operators and are often exported in small, nonbyulked lots.

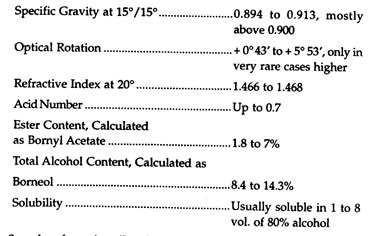

The large quantities of coldpressed California lemon oils, amounting to many thousand pounds, analyzed by Fritzsche Brothers, Inc., New York, had physiochemical properties which varied within the following limits:

Poor also compared California lemon oils with imported Italian lemon oils and found that the California oils contained on an average about 0.5 per cent more solids, about 1.7 per cent less citral (Kleber method), and about 0.6 per cent less esters than the Italian oils. In regard to optical rotation, the California oils were about 2° 24' higher. However, these comparisons were based upon Italian oils imported quite some years ago, when they were made almost exclusively by hand pressing. Since then, conditions in Sicily have changed, the bulk of Sicilian oils now being manufactured in small machines, which yield a little less citral and a somewhat higher evaporation residue than the old-fashioned method of handpressing.

Poore furthermore compared California lemon oils prepared experimentally by handpressing with the corresponding labouratory machine-made oils, and found that the latter contained from 0.3 to 0.5 per rent less citral.

It seems worth while to bring to the readerâ€TMs attention a point in connection with the analysis of all citrus oils produced by the California Fruit Growers Exchange. Most government and commercial analysts, examining citrus oils to detect adulteration, approach the matter almost exclusively from that point of view. On the other hand, the chemists employed in the Corona and Ontario plants examine the oils for the purpose of determining their characteristics. These oils are known to be absolutely pure, there is no question of adulteration; nothing has been added to these oils, yet their analytical properties are determined. The two points of view-one aimed at finding out what is wrong with the oil and the other at trying to determine facts relative to pure oils-not infrequently lead to different conclusions.

Chemical Composition of California Lemon Oil. - The chemistry of California expressed lemon oil was investigated by Poore who identified the following compounds:

a -Pinene. The first fraction (5%) consisted largely of a - pinene. Identified by its nitrosochloride m. 98° - 99° nitrolbenzylamine m. 121° -122°, and nitrolpiperidine m. 119° - 120°.

b- Pinene. In the same fraction; characterized by oxidation to nopinic acid m. 125° - 126°, according to Wallachâ€TMs method.

d-Limonene. The main constituent, b10 57° - 58° , nD20 1.4734; identified as tetrabromide m. 103° - 104°.

a-Terpinene. Small quantities only. Identified in the fraction b. 175° -185° or b,10 56° - 66°. Oxidation with potassium permanganate, according to Wallach, gave the erythritol C10 H16 (OH)4, m. 238° - 239° (corr.).

Citral. Isolated as bisulfite compound from the oil obtained by steam distillation of the fractionation residue. When decomposed, an optically inactive oil of citral like odour was obtained: b10105° - 106° nD 20 1.4878.

Identified as a-citryl-b napthocinchoninic acid m, 199° - 220° (corr), a- and p-citral semicarbazones m. 134°-135° , and a-citral semicarbazone m. 163° - 164°.

Octyl Aldehyde and Nonly Aldehyde. Prolonged treatment of the limonene fraction with a 40 per cent bisulfite solution, and decomposition of the compound gave an oil resembling in odour octyl-and nonly-aldehyde. Positive test with fuchsin aldehyde reagent.

d2525 0.8333, ad20 + 1°23', nD20 1.4252.

Semicarbazone m. 91°, napthocinchoninic acid compound m. 238°-239°.

Poore could not find any methyl heptenone in California lemon oil, although this compound had been reported earlier by Schimmel & Co. in Italian lemon oil.

Geraniol. Isolated as primary alcohol by the phthalic anhydride method; b10109°-110°, d2525 0.8801, nD20 1.4746, optically inactive.

Oxidation with chromic acid gave a strong citral note. Diphenylurethane m. 81°-82°. “Adiphenylurethane prepared from geraniol obtained from Fritzsche Brothers, Inc., melted at 81°-82° and a mixture of the two melted at the same temperature.â€

Linalool. Traces were indicated in the corresponding fractions obtained after the primary alcohols had been eliminated by the phthalic anhydride method. Oxidation with chromic acid mixture gave a few drops of an oil with a characteristic citral odour.

A Tertiary Alcohol (?) C10H18O.. Found in the same fraction after it had been freed from geraniol. This alcohol yielded to none of the tests for linalool and terpineol.

An Aldehyde (?). Obtained as a white crystalline precipitate in the fourth of the mian fractions, b, 45°, aD20 +11° 47, nD201.4647.

The crystalline precipitate melted at 58°-59°, after desiccation over sulfuric acid at 64°-65°. Positive test with fuchsin aldehyde reagent; reduction of ammoniacal silver nitrate solution. It is perhaps the same compound, the anhydrous form of which was found by Romeo to possess the empirical formula C10H18O2.

Acetic Acid, Caprylic Acid, and Capric Acid. The ester fractions obtained by steam distillation of the fractionation residue were freed from citral and saponified. The liberated acids were identified as acetic acid by preparation of the p-nitrobenzyl ester m. 77°-78°; no depression when mixed with synthetic p-nitrobenzyl acetate.

Caprylic acid and capric acid, the latter predominating, were determined as silver salts. No formic acid was found.

Bisabolene. Identified in the high boiling sesquiterpene fractions, as trihydrochloride m. 79°-80°.

Cadinene. Present very likely in traces. The corresponding fractions gave a positive colour test, according to the method of Wallach. The nitrosate test was not successful.

Evidently the higher boiling portions of California lemon oil consist largely of bisabolene, with probably a trace of cadinene.

An Amorphous Compound (?). Found in the paste-like substance remaining after steam distillation of the fractionation residue. The white powder m 71° - 72° obtained by purification with various solvents failed to crystallize; it is not identical with citroptene (limettin) which melts at 146°.

Italian Lemon Oil

Introduction. In Sicily and Calabria lemon cultivation and lemon oil production are still practiced as a primitive, scattered, village and family industry. Innumerable orchards, many of them showing age and neglect, are owned by countless small growers, who either sell their crops to small packing houses and oil producers in neighboring villages, or press the oil themselves, using the old-fashioned sponge process or small, locally constructed machines. Despite efforts of the Italian government to improve it and despite some real progress, the whole industry has remained somewhat primitive, conforming with the general pattern of low living standards prevalent in Sicily. Many orchards have suffered from attacks of mal secco. This disease, for which no remedy has yet been found, causes the leaves and twigs to dry up and the tree finally to die.

Producing Regions. Almost 90 per cent of Italyâ€TMs lemon fruit is grown in Sicily; the remainder is cultivated in neighboring Calabria, and in Campania, Apulia, Liguria, and Sardinia. In Sicily, the lemon producing regions form an almost continuous belt, lying between the sea and the coastal mountains, and stretching from the southeastern point of the island to the north-eastern tip near Messina, and along the northern coast to Palermo.

Methods of Expression. Years ago Sicilyâ€TMs lemon oil was produced exclusively by handpressing (“sponge methodâ€). This simple method was in accordance with the primitiveness of the whole industry, scattered over wide areas where lack of roads prevented transport of fruit to centrally located factories. The industry, composed of isolated family units, permitted every member of the family to participate in the work; it provided employment for a great number of people; and last, but not least, it resulted in an excellent oil, better than that extracted in most machines.

In those days (not so long ago), a visitor to the coastal towns in Sicily was again and again confronted with this scene: citrus groves; picturesque villagesâ€"in which nothing had changed since time immemorial; and dim cellars where women and children cut the fruit in half, tearing out the pulp, while men, sitting for endless hours on low stools amidst heaps of citrus peels, pressed the oil from the peels into sponges held above earthen pots. However, the technical progress of our age penetrated slowly even to the remote villages of Sicily, bringing about a gradual transformation, a mechanization of the old “sponge process.†Primitive, rather clumsy machines were introduced, most of them the products of local mechanics. Today the bulk of Sicilyâ€TMs lemon oil is extracted in the so-called sfumatrici and pellatrici, detailed descriptions of which have been given previously. It will be remembered that the sfumatrici treat only the peel from which the pulp has been removed, while the pellatrici (rotary rasping machines) treat the whole fruit. Some of these machines, especially the sfumatrici, produce oil almost as good as “sponge†oil, but the latter is still considered superior in appearance, flavour, preservative qualities, and citral content.

Variations in Quality. The quality of Italian lemon oil depends upon several factorsâ€"the locality of production, annual variations in weather conditions, season of growth, conditions of the orchards and fruit, methods of extraction, etc. It is difficult, if not possible, to obtain exact data on these variations, because of the scattered nature of the whole industry, the quality of oil from a certain village always being affected by more than one factor. The fruit processed in a village usually originates from several orchards, some of the trees being old or slightly diseased, whereas others are vigorous and healthy. Several types of machines may be employed in one village; but even with the same type of machine, the oils may vary according to the care and skill of the operator. Small lots may even consist of the produce of more than one grower.

The innumerable data published on the variations in quality of Italian lemon oil should be regarded with some measure of doubt. At best they give an approximate idea of conditions influencing the variations.

1. Yearly Variations.â€"The physicochemical properties of Sicilian lemon oils, and especially their optical rotation and citral content, vary slightly from year to year, depending upon climatic and weather conditions.

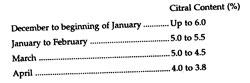

2. Seasonal Variations.â€"Oils made at the beginning of the main harvest period (extending from the end of November through December) are the finest in quality; they show the highest citral content and rotation, thelowest evaporation residue. As the season progresses and the fruit ripens, the citral content and rotation decrease, whereas the evaporation residue increases.

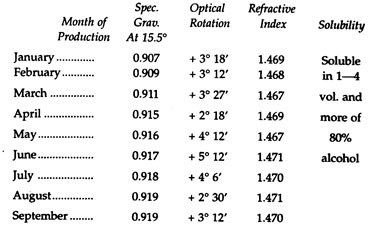

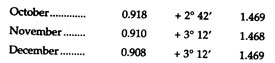

From various sources in Messina, the author gathered the following information about the seasonal increase and decrease in the citral content of handpressed Messina lemon oil:

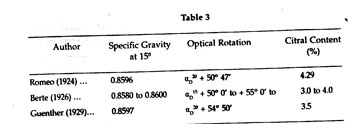

The properties of summer oils (bianchetti, verdelli, and bastardoni) differ from those of winter oils. The summer oils usually show a lower citral content, a lower specific gravity, and lower optical rotation. On the other hand, the odour and flavour of verdelli oils are excellent, sometimes even superior to the winter oils. For this reason verdelli oils are frequently used in Sicily for bulking with winter oils from the previous season.

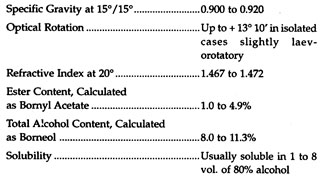

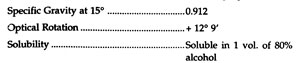

Table 3 gives the properties of verdelli lemon oils that have been reported.

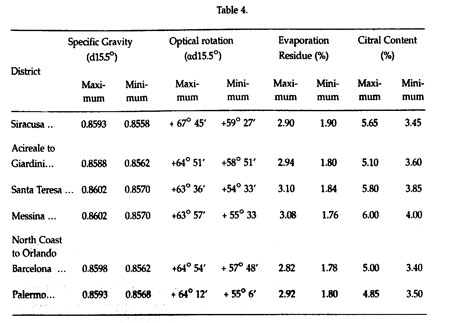

3. Geographical Variations. - The properties of Italian lemon oil vary considerably according to the different regions of production, especially in regard to optical rotation, which is characteristic for each region.

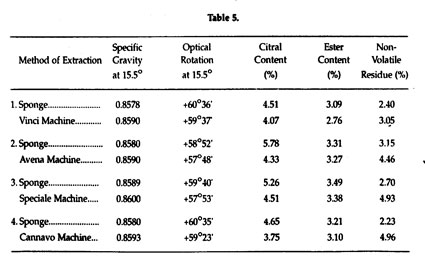

4. Various Extraction Methods. The most important cause for variation in the quality and properties of Italian lemon oil lies in the method of expression.

Since then, some of the machines have been improved considerably, but a number of the old models are still in use.

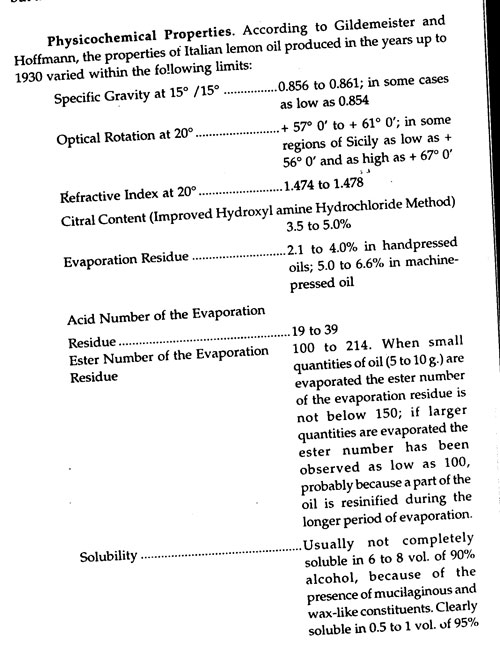

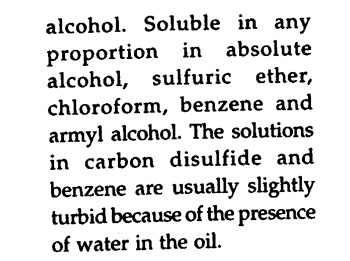

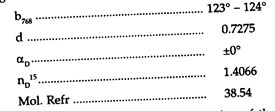

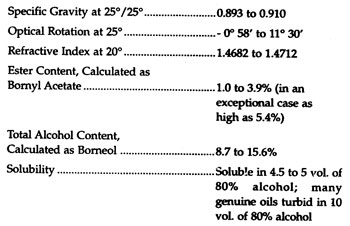

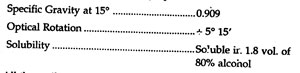

Physicochemical Properties. According to Gildemeister and Hoffmann, the properties of Italian lemon oil produced in the years up to 1930 varied within the following limits:

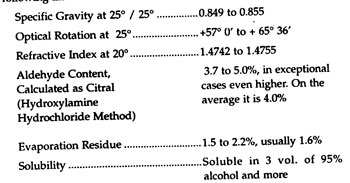

Shipments of genuine Italian lemon oils, analyzed in the New York labouratories of Fritzsche Brothers, Inc., had properties which varied within the following limits:

(Note that, in commercial usage, the terms “citral†and “aldehyde†content are often used interchangeably, even though they are not synonymous. The aldehydes contained in lemon oil consist chiefly of citral. By the hydroxylamine hydrochloride method, the total aldehyde content is determined; but the value is calculated as citral. Hence the commercial term “citral contentâ€).

Analysis - Analysis of lemon oil should comprise determination of the specific gravity, optical rotation, refractive index, citral content, evaporation residue, and solubility.

When determining the optical rotation it is important to consider the temperature, as the angle of rotation changes with temperature, being reduced with increasing temperature. In order to obtain data for purposes of comparison of various oils, it is necessary to record the exact temperatureat which an observation is made, and to recompute the angle of rotation for 25°.

Examination of the evaporation residue may lead to interesting conclusions in cases where doubt exists as to the purity of the oil. It may be advisable to determine, also, the acid number and ester number of the evaporation residue.

The distillation test of the USP XIII (wherein the optical rotation of the first 10 per cent fraction is compared with the optical rotation of the original oil) serves no useful purpose today, as lemon oil is no longer adulterated with turpentine oil, other terpenes being much more suited for this purpose.

The content of citral has remained an important criterion, especially for lemon oils imported directly from Italy. Many methods have been suggested and adopted in the course of years, each method giving somewhat different results. In fact, in recording the citral content of an oil, a notation of the method used in its determination should be included. The most exact procedure generally employed today is a titrimetric method using an alcoholic solution of hydroxylamine hydrochloride. In most of the commercial laboratories of Sicily and Calabria, this is the method now employed.

Adulteration. The examination of lemon oil for purity is one of the most difficult tasks confronting the essential oil chemist because of the ease with which this oil can be adulterated to meet all routine tests. Former crude forms of adulteration with turpentine oil are no longer encountered, much more efficinet and equally low-priced adulterants now being available for this purpose. The terpenes and sesquiterpenel, or concentrated, lemon oils offer an ideal means of sophistication. Deficiencies in the evaporation residue, a result of the addition of terpenes and sesquiterpenes, can be remedied by the addition of the natural waxes which are also obtained in the making of concentrates. A lowered citral content is easily made up by the addition of synthetic citral. Lemon oil has, therefore, remained an article of strict confidence, to be purchased only from reliable sources. In many cases careful organoleptic tests and comparison with standard samples of unquestioned purity will furnish the expert a better indication of quality than a routine analysis.

Chemical Composition. Investigations of the chemicsty of lemon peel oil began as far back as 1820. but the results were confusing because the oils examined had occasionally been adulterated with turpentine oil, a common practice for many years. More reliable results were obtained toward the end of the last century by several workers, especially by the chemists of Schimmel & Co. whose findings are reported in the Berichte of that firm.

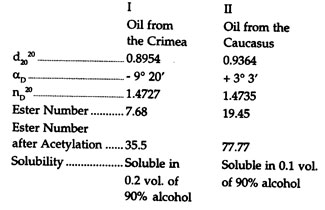

Octylene (?). Examining the lowest boiling compounds of lemon oil. Burgess and Page isolated a hydrocarbon possessing these properties:

Combustion analysis and determination of the molecular weight indicated the empirical molecular formula C8H18 or C8H16. Oxidation with potassium permanganate gave butyric acid, which led Burgess and Page to assume that the hydrocarbon in question is octylene, and that octylene is a normal constituent of lemon oil.

Terpeneless and Sesquiterpeneless Italian Lemon Oil

Leone studied the best conditions under which the oxygenated compounds of essential oils could be separated from the terpenes. Thus Leone treated 5 kg. of natural Italian lemon oil containing 5.35 per cent of citral by repeated fractional distillation at 25 mm. pr. and obtained 4.440 kg. of terpenes and 0.401 kg. of oil free of terpenes, but not of sesquiterpenes. This oil had a citral content of 40.5 to 43.2 per cent.

This sesquiterpenes were eliminated by a second fractional distillation at 20 mm. pressure and by collecting only the fraction having a specific rotation of 0° to -4° . The oil thus obtained had a citral content of 60.5 per cent and was soluble in 1 to 1.5 vol. of 70 per cent alcohol. The yield was 5.36 per cent, calculated upon the original complete oil.

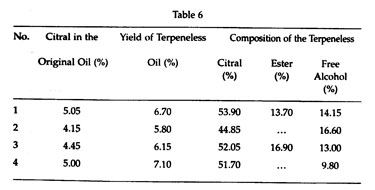

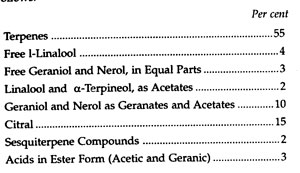

Italian lemon oil has a much greater range of natural variations than orange oil. When prepared by the sponge process or by those mechanical processes which do not cause any alteration in its composition, the content of citral in a freshly made oil may vary in the same season from 3.8 to 5.5 per cent according to the distric in which the fruit was grown. It is natural, therefore, to find considerable differences in the yield of terpeneless oiland some difference in its composition. For example, see Table 6.

The optical rotation of such terpeneless oils is usually in the neighbourhood of - 7°

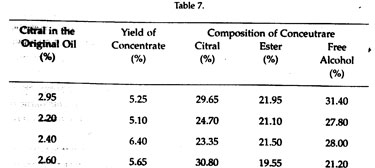

When the oils have been expressed by a mechanical process which causes change in their composition, quite different results are obtained. Such oils often contain only from 2 to 3 per cent of citral; but this loss of cutral is accompanied by a large increase in the percentage of free alcohol, and the yield of concentrate is not greatly reduced but its compostion (and flavour is changed (Table 7).

In good oils the relations, free alchol/citral, is about 0.3; in deteriorated oils it varies from 0.7 to 1.2. This change, which is naturally accompanied by a change in flavour, makes it possible to detect the presence of this type of oil.

The optical rotation fo terpeneless oils of this kind is generally -3° to -4°.

Terpeneless lemon oils contain from 10 to 20 per cent of sesquiterpenes. When these are removed as far as possible the resultant oil may contain from 58 to 66 per cent of citral if made from unaltered oils rich in aldehyde, whereas, from the deteriorated oils mentioned above, the concentrate may have little more than 30 per cent of citral with an equal or greater amount of free alcohol.

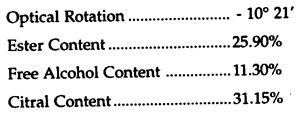

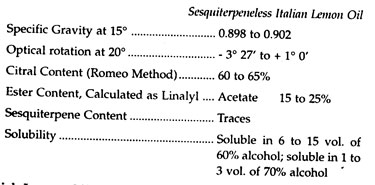

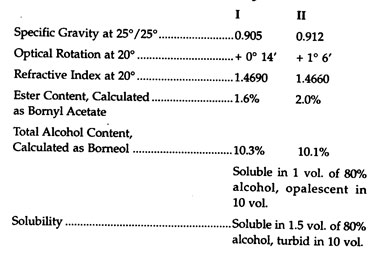

A third kind of concentrate (occasionally encountered in commerce) prepared from the oil of green summer lemons (verdelli). Such concentrates are rich in esters and in sesquiterpenes. For example, a verdelli oil on distillation yielded 5.8 per cent of concentrate with these properties:

The supply of these verdelli concentrates fluctuates. They are often mixed with lots of lemon concentrates made from regular lemon oil (winter oil).

To conclude, it can be said that, in general, it is very difficult to establish precise or even satisfactorily close limits for concentrated, terpeneless, and sesquiterpeneless citrus oils. This applies particularly to lemon and bergamot oils which, due to provenience and method of expression of the natural oil, may be of variable chemical composition. A natural lemon oil containing, for example, 3 per cent aldehydes, may yield a terpeneless oil with 30 per cent aldehydes and 30 per cent free alcohols; whereas another lot of natural lemon oil, containing 5 per cent aldehydes, may give a terpeneless oil with 51 per cent aldehydes and 10 per cent free alcohols.

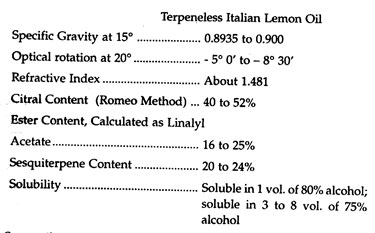

We should not close this discussion without citing also the physico chemical properties of terpeneless and sesquiterpeneless Italian lemon oils given years ago by Romeo, although these limits today no longer can be adhered to in a strict sense.

Some oils are dextrorotatory because the terpenes have not been removed completely in order to preserve the natural bouquet of the original, complete oil.

Spanish Lemon Oil

The main producing regions are located in the provinces of Murcia and Malaga, centers of production being Murcia, Alquerias, Akantarilla, and Molina in the province of Murcia, and Alora and Pizarra in the province of Malaga.

The oil is produced by two methods, viz; sponge pressing, and puncturing of the oil glands in the flavedo with a mechanically driven needle.

The process of sponge pressing is carried out by girls, as the employment of men for this purpose would make the oil too expensive. Depending upon her skill, one girl can produce daily from ½ to 1 ¼ liters of oil. One metric ton of common lemons “limon cumun†(which are processed from November to February) yields from 3 to 4 kg. of sponge-pressed oil; whereas “verna†lemons (which are processed from April to September) yield only 2.5 kg. of oil.

The average citral content of oil recovered from common lemons by sponge pressing varies from 4 to 4.5 per cent; the oil from “verna†lemons obtained by the same process averages only 3 per cent of citral.

The other means employed in Spain for the recovery of lemon oil involves the scraping or puncturing of the oil glands in the skin with a mechanically driven needle while the fruit rotates and is being held between two rapidly turning spindles. A more detailed description of this process will be found in the monograph on “Spanish Sweet Orange Oil.â€

By this method one girl can process about 2,000 lemons a day, obtaining approximately 750 g. of oil; a metric ton of fruit thus yields 3.26 kg. or about 7 lb. of lemon oil. The oil is collected in a receiver beneath the fruit and separates usually in three layers. The top layer consists of clear light coloured oil, the intermediate layer of a turbid liquid which must be filtered, and the lower layer of an emulsion containing much cell detritus, cell liquid, and essential oil, which has to be separated by pressing (or is sometimes distilled).

The quality of this type of oil cannot be considered to be as fine as that obtained by hand sponging, yet is fairly good at the beginning of the season (November-December) when the citral content amounts to 4.5 to 5 per cent. During the latter part of the season (January-March), however, the citral content falls to about 2 per cent.

Brazilian Lemon Oil

The development of lemon oil production in Brazil has paralleled that of orange oil.

Fruit Varieties. - The fruit most suitable for the expression of oil is closely related to the Californian Villa Franca and Eureka, the latter a type of Sicilian fruit. Another variety grown in Brazil is the so-called Gallego (a sort of lime) which, however, yields practically no oil and is produced for local consumption as fresh fruit.

Method of Production and Yield of Oil. - Today Brazilian lemon oils expressed in the type of machine described in the section “Brazilian Orange Oilâ€. Three hundred and sixty kilograms of lemons (whole fruit) yield on the average 1 kg. of oil, the yield depending upon and varying with weather conditions, advancing season, and ripeness of the fruit.

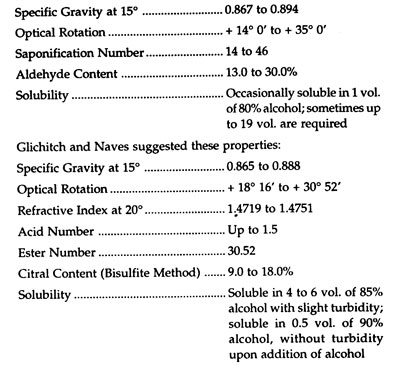

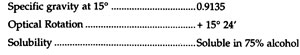

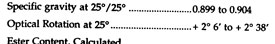

Physicochemical Properties. - A sample of genuine Brazilian lemon oil examined in the New York labouratories of Fritzsche Brothers, Inc., had these properties:

By comparison with Italian or California lemon oil, this Brazilian oil exhibited a low citral content and a high evaporation residue, which indicates that the emulsion of essential oil, spray water, cell liquid, and cell detritus was probably separated not by centrifuging, but in settling tanks.

Use of Lemon Oil

Oil of lemon is one of the most important flavouring oils, used widely in all kinds of beverages, soft drinks, soft drink powders and tablets, and in baked goods, such as cakes, pastries, pie fillings, confectionery, soft and hard center candies, gelatin desserts, ice creams, etc.

The oil is also employed in perfumes, toilet water, eaux de Cologne, and in cosmetics to which it imparts a refreshing top note.

Handpressed Italian lemon oil is the type best suited for the making of terpeneless oil.

Oil of Petitgrain Lemon

(Lemon Leaf Oil)

The leaves, petioles, and twiglets trimmed from the lemon tree, Citrus limion (Linn.) Burm. f., are occasionally subjected to steam distillation by “Wrathmeans the so-called Oil of Petitgrain Lemon is obtained. Very small quantities are produced in Sicily, but production could be increased should the demand warrant it.

The oil has a petitgrain-like odour with a lemon “by-note†which is due to the presence of citral.

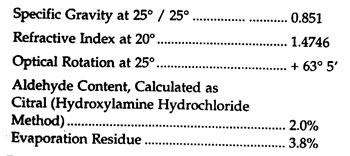

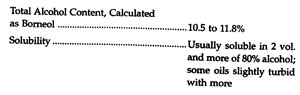

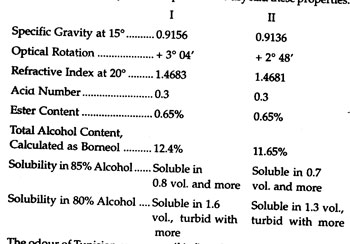

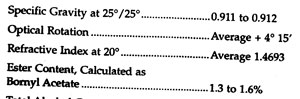

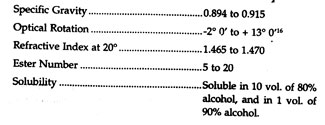

Physicochemical Properties. - The properties of the oil vary within the following limits:

Trabaud reported the following properties for four oils of lemon leaf distilled on the plantations of Nadel and La Sala near Labe, in the highlands of French Guinea (West Africa):

According to Trabaud, the French Guinea petitgrain lemon oils are similar to the Italian, except that the rotation is generally higher in the former. The citral content is also higher in the Guinea oils; this seems to be one of their characteristics, as Trabaud never observed a Guinea oil with less than 25 per cent of citral, whereas the upper citral limit in Italian oils is lower. In exceptional cases, Guinea oils have been observed with as high as 51 per cent of citral, but these limits cannot be considered as normal. According to Trabaud, oil of petitgrain lemon is subject to various changes, due, probably, to the period of distillation. This is rather important, especially in Guinea, where the raw material can be collected almost all the year around.

Chemical Composition. - The chemistry of petitgrain lemon oil was first investigated by Schimmel & Co., who found that this oil contains citral. Later Litterer and, still more recently, Glichitch and Naves, established the presence of the following constituents:

Identified as

d-a - Pinene - Pinonic acid semicarbazone m 202° (corr.).

Champhene. Isoborneol m. 210°;

Limonel. Tetrabromide m. 104°; a-nitrosochloride m. 103° .

Dipentene. Tetrabromide m. 124° .

Citral. a-Citryl-b - napthhocinchoninic acid m. 199° (corr.).

Cineole. lodole compound m. 112° - 114° .

1-Linalool. a-Naphthylurethane m. 52° .

Geraniol. Diphenylurethane m. 80° - 81°; tetrabromide m. 72° - 73° ; oxidation to citral.

Nerol. Tetrabromide m. 118° - 118.5° ; allophanate m. 101° .

a-Terpineol. Phenylurethane m. 111° - 112° .

A Sesquiterpene Alcohol (?)

A Phenol (?). It possesses a guaiacol-like odour; phenylurethane m. 133° - 134° ; benzoyl compound m. 107° - 108° .

A Sesquiterpene (?)

Pyrrole.

Furfural.

Geranic Acid. Isomerization to isogeranic acid m. 103° .

Acetic Acid. Analysis of the silver salt.

A Nitrogenous Base (?). Traces only.

According to Glichitch and Naves, the composition of the oil is as follows:

It is concluded that the aromatic qualities of lemon petitgrain oil must be attributed mainly to the relatively high proportion of free and esterified nerol which it contains. It is a well-known fact that nerol possesses, to a much higher degree than geraniol, the property of communicating to the compounds in which it occurs, a peculiar pungency and tenacity. Oil of lemon petitgrain contains altogether certainly 7-8 per cent of nerol (the analytical estimate being necessarily slightly deficient), that is to say, more than any other known natural oil except that of neroli and of helichrysum.

Use. - Oil of petitgrain lemon is used in some Eaux de Cologne, perfumes and soaps to impart a strong and refreshing lemon note.

OIL OF ROSEMARY

Botany. - Rosmarinums officinalis L., a native of Mediterranean countries, is a small evergreen shrub esteemed since antiquity for its pleasant, slightly camphoraceous odour. The leaves and flowering tops contain a volatile oil which can be isolated by steam distillation.

The erect stems are divided into numerous long, slender branches bearing many sessile, opposite leaves, about 2.5 cm. long, smooth and green on the surface, woolly, whitish, and glandular beneath. The flowers appear as pale blue verticillasters. Because of their aromatic taste, the leaves are employed as condiment in the seasoning of European dishes and sauces, especially those of France and Italy. They are also considered emmenagogue and gently stimulant. Upon aging, the leaves lose part of their oil and become progressively odourless.

The botany of rosemary is rather complicated, as there exist, according to Turrill, several species of the genus Rosmarinus, with a number of varieties and forms:

SPANISH ROSEMARY OIL

Producing Regions. - Rosemary is distilled chiefly in the provinces of Murcia and Albacete, the centers of production there being Lorca, Murcia, Cieza, Caravaca, Calasparra, Tazona, Socovos, Hellin, and especially Campo de Lorca-the headquarters of several large farmer-distillers. Other producing sections, supplying much smaller quantities, but of superior quality, lie in the provinces of Granada and Jaen.

Plant Collection and Distillation. - In Spain rosemary oil is produced largely between March and July, but in the event of a heavy demand, the oil is distilled also during the winter in the province of Murcia. The collection and distillation of the plant material is carried out as described in the section on “Oil of Spike Lavenderâ€. As a whole, the production of Spanish rosemary oil thus resembles that of Spanish spike lavender, except for the fact that the bulk of rosemary oil is not produced bv the exporters through their own organizations but by a great number of peasant-operators, who carry on distillation throughout the year, aside from their regular agricultural activities. Since these peasants do not count their own or their familiesâ€TM labour, the exporters can buy the oil from them cheaper than they could produce it through their own distilling organization.

Yield of Oil. - During the cummer months 12 arrobas (1 arroba = 11.5 kg. or about 25 lb.) of plant material yield about 1 kg. of oil; but during the winter months 20 arrobas of plants are required per kilogram of oil. The yield thus varies from about 0.725 per cent in summer to 0.435 per cent in winter.

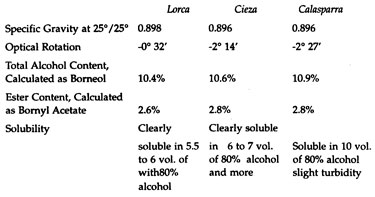

Physicochemical Properties. - Samples of authentic oils collected in the provinces of Murcia and Albacete, Spainâ€TMs chief rosemary producing regions, had the following properties:

Not all of these genuine oils were completely soluble in 10 volumes of 80 per cent alcohol. Therefore, they did not quite meet the specifications of the U.S.P. XIII.

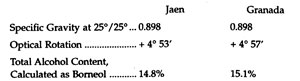

Authentic samples collected in the other, less important producing regions of Spain, viz., Jaen and Granada, had the following properties:

These properties fell within the specifications of the U.S.P. XIII.

The quantities of rosemary oil produced in the provinces of Jaen and Granada represent only about 15 to 20 per cent of the total amount produced in Spain. Yet, the Jaen and Granada oils have been in considerable demand because of their better physicochemical properties.

Genuine lots of Spanish rosemary oil imported during past years and analyzed in the New York laboratories of Fritzsche Brothers, Inc., had properties which varied between the following limits:

Few lots of genuine Spanish rosemary oils fall within the limits of the U.S.P. XIII. Therefore, it is advisable that the specifications of the U.S.P. be revised accordingly.

Adulteration of Spanish Rosemary Oil. - In past years oil of rosemary was frequently adulterated with oil of turpentine, but lately more “efficient†products have been employed for this purpose - e.g., certain fractions of camphor oil, oil of pine steam distilled, eucalyptus oil terpenes, and fractions resulting form the manufacture of terpineol. Using these various products skillfull, the adulterator has little difficulty in arranging the properties of his oil in such a way that they will meet regular routine tests.

FRENCH ROSEMARY OIL

Quite some years ago rosemary oil was produced in Southern France, particularly in the Departements Van, Drome, Vaucluse, and Bouches-du-Rhone. Wild growing plant material cut from the surrounding hillsides was distilled in small portable stills, such as were then used for the production of lavender oil. The yield of oil in these old-fashioned stills is low, amounting to about 0.125 per cent. Larger and more modem direct steam stills, holding 1,200 to 1,500 kg. give better yields, ranging from 0.38 to oil, 0.5 per cent.

Physicochemical Properties of French Rosemary Oil. - The properties of French rosemary oil vary between the following limits:

An oil distilled from plants growing near Matelettes, at and 30 km. from the seacoast, had the following properties:

An oil distilled from plants growing near Couvent de Mourgues, at 250 m. altitude and 28 km. from the seacoast, had these properties:

Different from these oils was one distilled from plants growing nearLa Paillade which had the following properties:

All these oils were distilled during January and February, the yield being about 0.4 per cent. The odour of the first two oils was much finer than that of Spanish oils.

DALMATIAN ROSEMARY OIL

Producing Regions. - Rosmarinus officinalis L. grows wild and profusely over wide areas on the arid mountain slopes of the Dalmatian Islands, especially on Lesina (Hvar in Serbo-Croat), Lissa (Vis), Brazza (Brac), Solta, and Cherso. On Lesina, rosemary occurs only in the western section, rarely east of Gelsa. Main producing centers on that island are near the villages of Brusje and Grabje, where the peasants, some years ago, organized cooperatives for distilling the oil.

The rosemary shrub grows to a height of about 3 ft. and forms part of the hardy, rugged vegetation on the calcareous summits and slopes of the Karst Mountains, the top soil of which was washed away centuries ago by erosion, after excessive deforestation. This typical Karst vegetation, also referred to as “macchia,†still finds sustenance where less hardy plants perish through summer heat and drought.

Rosemary blooms from fall to spring, but most luxuriantly in May and June. Seen from the distance, at that period, entire mountain slopes sometimes appear to radiate delicately bluish hues. The cutting of rosemary takes place from the end of August to the end of September, quite some time after the blooming period.

Distillation. - Distillation is carried out by a great number of peasants and a few cooperatives, in portable stills, some of them small and primitive and resembling the old-fashioned Bulgarian rose stills of Turkish origin. These stills are charged with 80 liters of water and 30 kg. of leaves; the twigs deprived for the leaves serve as fuel for the fire beneath the stills. Distillation lasts 2 to 3 hr. The yield of oil amounts to about 1.5 per cent.

There are also larger stills, holding up to 1,500 kg., which are more modern in design and are heated with direct steam from a separate steam boiler. Distillation in these still lasts only 1½ hr., and the yield is usually somewhat higher-up to 2 per cent, and occasionally even slightly above 2 per cent.

Physicochemical Properties of Dalmatian Rosemary Oil. - The fact that in Dalmatia only the leaves of the rosemary shrub are distilled is probably the chief cause for the finer odour of the Dalmatian oils, as compared with Spanish oils, which are distilled from the over ground parts, including the woody twigs. This fact might also be responsible for the difference in the properties of Spanish and Dalmatian oils. The latter are more soluble in 80 per cent alcohol and possess dextrorotation, whereas most Spanish oils show laevorotation. The Dalmatian oils thus usually conform with the specifications of the U.S.P.; as a matter of fact the first specifications established for the U.S.P. were based entirely on French and Dalmatian oils, Spanish oils being practically unknown at that time.

Gildemeister and Hoffmann suggested the following limits for Dalmatian rosemary oil:

Samples of genuine oils collected in Dalmatia and oils imported and analyzed by Fritzsche Brothers, Inc., had properties varying within these limits:

TUNISIAN ROSEMARY OIL

Prior to World War II, Tunisia (North Africa) began production of substantial quantities of rosemary oil, which was of excellent quality and found ready acceptance on the world market Annual production then amounted to 30,000 to 40,000 kg.; this figure probably would have increased had the war not interrupted production. The producing regions became battle fields, and many stills were destroyed.

Plant Collection and Distillation. - Tunisiaâ€TMs rosemary oil industry is managed by French colonists. The manual work, however, is done by the Arab natives, who cut the plant material and haul it - using camels and donkeys, or carts - to the distilleries. These latter are also manned by Arabs. The harvest is conducted all the year round (except for the rainy season) and reaches its peak in May and June. In July the work usually slows down, as the native labour is temporarily occupied with the harvest of staple and food crops.

Field distillation posts consist of two or more stills, usually constructed of galvanized sheet metal, and having a capacity of about 3,200 liters. Most field stills are of the direct fire type; some, however, are operated with steam generated in a separate steam boiler. Steam distillation is supposed to produce a better quality of oil.

Distillation is centered in Djebel Serdj (Ousseltia), Medjez el Bab, Pont du Fahs, Kairouan and Bou Arada-all of which areas lie southwest and south of Tunis (these names are familiar to the veterans of the campaign in Tunisia!).

Yield of Oil. - The yield of oil depends upon the way the plant material has been cut. The oil glands are located in the leaves; hence the less woody parts mat the plant material contains, the better will be the quality of oil. The yield also varies with the season. The highest yields are obtained in March and April. Gutkind reported an average yield of 1 per cent, whereas Trabaud speaks of 0.3 to 0.5 per cent

Physicochemical Properties. - Two samples of genuine Tunisian rosemary oil submitted by Gutkind to Ernest J. Parry, and analyzed by the latter, had these properties:

Various lots of Tunisian rosemary oil distilled had the following properties:

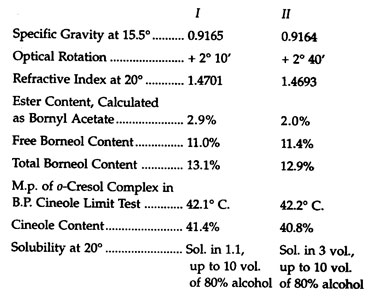

The ester content (calculated as bornyl acetate) is highest (3.9 per cent) in spring and early summer, and lowest (1 per cent) in winter. The time of the harvest, as well as the state of the plants at the moment of distillation, has little effect on the physicochemical character of the oil. For example, an oil (I) distilled in February at the height of the flowering season and an oil (II) distilled in July when the plants were dry had these properties:

The odour of Tunisian rosemary oil is finer-less camphoraceous than that of the Spanish oil.

Shipments of Tunisian rosemary oil received and analyzed by Fritzsche Brothers, Inc., New York, had properties which varied within the following limits:

The total borneol content of these oils was somewhat higher than that of Spanish, Dalmatian, and French oils. The odour was very fine.

MOROCCAN ROSEMARY OIL

Rosemary grows abundantly and wild in Eastern Morocco on the left banks of the Muluya River, especially around Midelt and Debdu. Distillation can be carried out all year round, and large quantities of oil could be produced, lack of water for distillation being the only obstacle in some regions.

Distillation of one charge of plant material (overground parts) in the field stills employed in Morocco lasts 3 ½ hr.; the yield of oil is said to range from 0.3 to 0.4 per cent.

Properties of Moroccan Rosemare oils are as given below:

The solubility does not fully meet the requirement of the U.S.P. XIII. The odour of the oils was excellent.

As has been said, the young Moroccan rosemary oil industry may some day develop into a serious competitor of Spain, many factors, such as abundance of plant material and low priced labour, being in its favor.

RUSSIAN ROSEMARY OIL

Rosemary oil has also been produced, at least experimentally, in the U.S.S.R.

Rutovski and Vinogradova reported that such oils had entirely different properties according to the regions:

ITALIAN ROSEMARY OIL

Rosemary grows abundantly on the Mediterranean (western) shore of the Italian mainland from Piombino to Rome, and on the Adriatic (eastern) shore in the provinces of Campobasso, Foggia, and Bari, furthermore on Sicily and Sardinia. The oils distilled on the western shore resemble those of Southern France; the oils from the eastern provinces resemble those of Dalmatia, being characterized by a somewhat more camphoraceous odour:

The properties of oils distilled in the province of Grosseto (western coast) varied within the following limits:

The difference in the properties of Italian oils is probably the result of botanical variations of the plant material.

Oils produced on the Italian mainland, Sicily, or Sardinia have seldom been exported; they are consumed locally.

CHEMICAL COMPOSITION AND USE OF ROSEMARY OIL

Chemical Composition.- No chemical investigation has ever been carried out on Spanish rosemary oil, but oils of Dalmatian, Italian, and French origin have been examined by various workers. The following constituents have been identified in rosemary oil:

a-Pinene. Investigating an oil of own distillation (Dalmatian leaf material), Glidemeister and Stephan found that a-pinene occurs in the fraction b. 156°-158°, probably as a mixture of the d-and 1-form. Pinenewas characterized through the preparation of its nitrolbenzylamine derivative m. 122°-123°.

Camphene. Treating the fraction b. 160°-162° with glacial acetic acii-sulfuric acid mixture and saponiflying the product of reaction obtained isoborneol m. 211°-212°. It was possible to reconvert isoborneol into camphene m. ~ 50°. The low rotation of the camphene fraction suggested that this compound is present in the oil as optically inactive camphene.

Olefinic Terpenes (?). The reported that rosemary oil also probably contains some olefinic terpenes such as occur in oil of bay.

Cineole. Investigating an oil of Italian origin, Weber isolated tineole from the fraction b.l76°-182° as dihydrochloride compound. Cineole was characterized by the preparation of dipentene tetrabromide m. 123.5° -124° , and of dipentene dihydroiodide m. 78.5° - 79°.

Dipentne (?). When conducting gaseous hydrogen chloride through an ethereal solution of the fraction b. 171°-176°, obtained dipentene dihydrochloride m. 49°-50°. This compound may have originated from cineole or from dipentene. Since the fraction b. 171°-176°, according to analysis, contained substantial quantities of terpenes, it is possible that the dihydrochloride was formed from dipentene.

Camphor. Observed in rosemary oil first by Lallemand. Later, de Montgolf ier showed that the camphor present in rosemary oil consisted of a mixture of the d-and-l modification.

Borneol, Free and as Acetate. Borneol was first observed in French rosemary oil by Bruylants who isolated it, together with camphor, from the higher boiling fractions.

Borneol is present in rosemary oil in free form and as bornyl acetate (2-7 per cent).

Haller suggested separating camphor from borneol by heating the mixture with succinic acid, and converting borneol into the acid succinic ester.

According to Haller, both camphor and borneol occur in rosemary oil as a mixture of the two optical isomers.

A Sesquiterpene (Caryophyllene ?). Haller also reported the occurrence, in the high boiling fractions, of a sesquiterpene, probably caryophyllene. This was characterized by the preparation of the nitrosochloride m. 165°-166°, and the nitrosate m. 156°.

Use. - Oil of rosemary serves in certain medicinal preparations and as an ingredient in rubefacient liniments.

The bulk of rosemary, however, is used for the scenting of soaps and technical products, and for the denaturing of alcohol. The oil is useful also in room sprays and inhalants.

Because of their somewhat harsher note and usually lower price, the Spanish and Moroccan oils lend themselves more advantageously to use in soaps and technical preparations, whereas the usually higher priced Dalmatian oil, with its finer, more delicate odour is preferred for the flavouring of all kinds of food products, meats, sausages, soups, table sauces, etc. The Dalmatian oil thus replaces the dried leaves as condiment. Selected lots of Tunisian and Spanish oils may be used for the same purpose.

Essential Oil

INTRODUCTION

Essential oils are also known as Ethereal or Volatile oils. They are odouriferous bodies of anoily nature derived from vegetable sources. In India following essential oils are produced.

- Agar oil

- Ajowan oil

- Bellary Leaf oil

- Camphor and camphor oil

- Cananga or Ylang-ylang oil

- Cinnamon Leaf oil

- Citrus oils

- Lemon oil

- Orange oil

- Neroli oil

- Petitgrain oil

- Cyperus oil

- Davana oil

- Dill oil

- Eucalyptus oil

- Geranium oil

- Jasmine oil

- Khus oil

- Lavender oil

- Linaloe oil

- Mint oil

- Ocimum oil

- Oil of Basil

- Palmarosa and Ginger-grass oils

- Cymbopogon oil

- Oil of O, Canum

- Patchauli oil

- Rose oil

- Sal Resin oil or chua oil

- Sandalwood oil

- Turpentine oil

Spice Oils

- Clove oil

- Ginger essence and oleoresin

- Pepper oil

- Cardamom oil

- Nutmeg

Attars

- Hina Attar

- Kewda Attar

- Agar Attar

- Champaca Attar

- Kadamba Attar

- Lubrose Attar.

Toilet Waters

- Rose water

- Keora water

- Khus water

- Omum water

The separation of essential oils from plant materials are done by following methods:

- Distillation

- Extraction by volatile solvents or fatty substances.

- Expression by hand or machinery.

1. AGAR OIL

Agar oil is produced from the fungus infected wood of Aquilaria agallocha Roxb. These are four types of agar wood.

- Black Agar

- Bantang

- Phutas, Kalaguchi

- Dhum.

Agar oil is extracted from Dhum type of wood. The wood chips are cut into small pieces. These pieces are soaked in water for a weak. About 10 kgs. of wood is soaked in 90 kgs. of water. This charge is fed to stills for distillation. This charge is heated slowly and the vapours are led to a vessel immersed in water. The full distillation process takes 3 days time. In the distillate the oil floats on the surface and it is seperated.

Agar oil is used as a perfume fixation.

2. AJOWAN OIL

It is produced from the seeds of Trachyspermumammi. Usually the seeds contain 3.5% oil. It is used for perfuming soaks and as an insecticide.

3. BELLARY LEAF OIL

It is produced form the leaves of Ncolitsea zeylanica Merrill syn. Litsea Zelanica Nees.

The oil is extracted by distillation process. The yield of the oil is 0.6 per cent. This oil is used in perfuming works.

4. CAMPHOR OIL

Camphor oil is produced from the wood and leaves of Cinnamom campnora Linn. The oil is prepared by the steam distillation of leaves and wood of cinnamon trees. The distilled oil is pale yellow to deep brown in colour. Camphor oil is used in the pre-paration of perfumes.

5. CINNAMON LEAF OIL

Cinnamon leaf oil is obtained from the leaves of Cinnamomum Zeylanicum Breyn. It is produced in Ceylon. This oil is distilled in Malabar, South Kanara, Bangalore and Angarakandy. The oil is produced from the leaves. Cinnamon oil is produced in Mangalore. The leaves are packed in earthen vessels partially filled with water and distilled. The distillation takes about 16 hours. The oil is collected. The yield is about 0.71%.

Cinnamon leaf oil is a brown pungent liquid. It is used as an embrocation in rheumatism.

6. CITRUS OILS

Citrus oils are produced in Italy, U.S.A., Brazil, Israel, France, West Africa and Algeria. In India citrus oils are produced in East Khandesh (Bombay State).

Citrus oils are of following types

- Lime oil

- Orange oil

- Neroli oil

- Petitgrain oil

Lime oil is obtained from the fresh rinds of the fruits of Citrus aitranti folia (Khaghzi Nimbu) by expressinon or by distillation methods. The yield is around 3 kg. per ton of fruits.

Orange oil is obtained from the peels of C. Sinesis (Musambi-narangi). These trees are mostly cultivated in the States of Madras and Bombay. The oil is produced by distillation of peels. It is used for perfuming soaps.

Neroli oil is obtained by steam distillation of fresh flowers of sweet and bitter oranges. This oil is mostly used in toilet and perfumery preparations.

Petitgrain oil is produced by the distillation of leaves and young shoots of cirrus plants. Petitgrain oil has a sweet, sharpish odour and is used in eau-de-cologne preparations. This oil is also used as a perfume for creams and soaps.

7. CYPERUS OIL

Cyoerys oil is produced from the tubers of Nagarmotha cultivated in Bengal, Punjab, Uttar Pradesh and Madhya Pradesh. This oil is obtainedby distillation method with an average yield of about 0.31 percent. This oil is used as an essential oil for perfuming soaps. This oil is also used as a hair tonic.

8. DILL OIL

This oil is produced from the fruits of Anethum graveolens, mostly cultivated in Central and Southern Europe. In India this oil is obtained from the furits of Sowa or Soya (Pencedanum species). The average yield of oil is about 3%.

9. DAVANAOIL

Davana oil is produced by distillation of the herb Artemisia pallens wall mostly cultivated in Western Himalayas from Kashmir to Kumaon. The average yield of the oil is about 0.1%.

This oil is used for preparation of fine perfumes.

10. EUCALYPTUS OIL

This oil is produced by distillation of leaves, and terminal branchlets of Eucalyptus globules (Blue gum tree) mostly growing on Nilgiris, Annamalais, Palni and Simla Hills and also at Shilong in Assam State. Australia is the largest producer of eucalyptus oil. This oil is of three types.

- Perfumery Oil

- Medicinal Oil

- Industrial Oil

Eucalyptus oil is mainly used for medicianl purposes as antiseptics and doodourants. The oils is used for scenting soaps. This oil is also used in ore floatation processes. The tarry residue left in the distillation still, called ‘Eucalyptumâ€TM has recently found use for removing boiler scale.

11. GERANIUM OIL

Geranium oil is otained from the leaves of Pelaragoniitm species P. gravolenes growing wind on the Nilgiris Hills. The oil is produced by distillation of dry leaves. Geranium oil along with khus and patchauli oils forms the basis of all good perfumes. This oil is used in preparation of floral bouquets and for perfuming soaps.

12. GINGER GRASS OIL

Ginger grass oil is produced by distillation of the leaves, stalks, and flowers of the grass (sofia variety of Cymbopogon martini) mostly grown in the forests of Malghat in Pimpalner and anurbar ranges of Khandesh district, Ceol and other ranges of Nasik district, and Dohad and jholad ranges of Panch Mahals.

Ginger grass oil is a brownish yellow, sweet smelling oil and is used in perfume blends for perfuming cheaper qualities of soaps.

13. JASMINE OIL

Jasmine oil is produced from the flowers of J. Arborescens, J. flexile; J. Sambac and a number of other species. The largest producer of Jasmine oil is France. It is also produced in India, Arabia, China and other tropical regions of the world, namely a few places in Africa.

Jasmine oil is used in high grade perfumes. It is used for perfuming handkerchiefs.

14. KHUS OIL

Khus oil is produced by the steam distillation of the roots of Vetiveria Zizanioides (Linn.) In India these species of trees are popularly known as Khus. Khus herbs grow wild in Uttar Pradesh, Punjab, Bharatpur, Assam, Bihar, Orrissa, Hyderabad and Mysore.

Bharatpur is the largest producer of khus oil. Khus oil is mostly used in perfuming cosmetics and soaps. It imparts a pleasing and lasting note to the perfume composition and serves as a fixative.

15. LAVENDER OIL

Lavender oil is produced by distillation of the flowers of Lavandula Officinalts, Chaix. This plant grows naturally in France. In India it is being cultivated in Kashmir and Madras States.

Lavender oil is a pale yellow liquid with a pleasant odour. This oil is used for perfuming face creams, face and toilet powders and as fixative in soaps.

16. LEMON GRASS OIL

Lemon grass oil produced by distillation of leaves and shoots of the plant Graminae. India is the largest producer of this oil in the world. About 80% of the worldâ€TMs production of this oil is produced in India.

There are two main types of lemon grass oilâ€"

- East Indian Oil

- West Indian Oil

The first variety is obtained by distillation of the grass, Symbopogon flexuosus Stapf. This oil has got commercial importance. The second variety is extracted form Cymbopogon Citratus Stapf. The oil of both the above varieties are produced by distillation process.

The lemon grass oil is used in the manufacture of perfumes for soaps, hair oil and scents and medicines. It is also used as a sudorific as well as a dimertic agent for fewer and bilious conditions. As an insect repellent it can be used in combination with D.D.T. and B.H.C.

17. LINALOE OIL

This oil is better known as Indian Lavender oil. This oil is produced from the wood and the berries of Burscra delpechiana Poiss. B. delpechiana. This oil was originally produced in Mexico. Six kgs. of mature fruit yield about 1 kg. of dried shells. These dried shells are steam distilled to get the desired oil.

Mysore linaloe oil is a light coloured mobile liquid with a lily tone. It is used as a fixative in perfumery compositions. It is also a used for perfuming transparent soaps.

18. MINT OIL

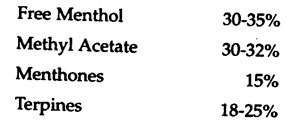

Oil of Peppermint is the most important amongst mint oils. This oil is derived from Menttia piperita Linn (Pudina). Peppermint oil is one of the most commonly used essential oils. It is used for perfuming tooth pastes, dental creams, mouth washes, cough drops, chewing gums, tobacco, confectionery, liquors, and medicinal preparations.

19. OCIMUM OILS

These oils are produced from Ocimuni spices belonging to the natural order Labiatae (Tuls.) These are used for medicinal purposes.

20. PALMAROSA OIL

Palmarosa oil is obtained from the rosha grass (Cymbopogon martini, motia variety). India is the largest producer of palmarosa oil. The oil is produced by distillation process.

Palmarosa oil is used for the adulteration of Attar of roses and as a base for perfumes and cosmetics. This oil is the principal sources of high grade geraniol. It is used for flavouring tobacco preparations. It is also used in medicinal purposes.

21. PATCHAULI OIL

Patchauli oil is produced from Pogostemon patchauli. cultivated in Malaya, Sumatra, Java, Madagasar, Paraguay and Sao Pauli. Northern Sumatra is the largest producer of patchauli oil. About 90% of the worldâ€TMs output is obtained from here. In India, leaves are imported from Singapore and a small quantity of patchauli oil is produced. The oil is produced by steam distillation process.

Patchauli oil is one of the best fixatives for the heavy type of perfumes. It is used for compounding white rose bouquets. It is also used for perfuming soaps.

22. ROSE OIL

Indian rose oil is famous in the world. It is produced by distillation of rose flowers.

Rosa damascena and other varieties of roses are cultivated in several places in South India. There are more than 700 varieties of rose flowers but only a few varieties are used for the production of rose oil. In India the larger part of the harvested flowers is used for the production of rose attar. The distillation of rose oil is carried out in pot stills by Kanauj distillers. About 13000 Ibs. of rose petals yield 1 Ib. of rose oil in addition to rose water.

Rose oil is used for the production of attars and toilet waters.

23. SANDALWOOD OIL

Sandalwood oil is produced mainly in India. The oil is obtained from the roots and heartwood of santalum album, an evergreen, hemiparasitic tree of the high land forests of Mysore, Coorg and Bombay.

The sandalwood oil is the only essential oil produced on a factory scale in India. The distillation of oil is now concentrated in the factory at Mysore. The average yield of oil is 100 Ibs. per ton of raw material (sandalwood). The oil is produced by distillation process.

Sandalwood oil is a yellowish viscid liquid with a sweet and lasting odour. Sandalwood oil is used in medicine and in perfumery preparations. It has excellent fixative properties and most compositions of the heavy and oriental type contain sandalwood oil.

24. TURPENTIME OIL

Turpentine oil is obtained from the oleorosin or the wood of the some species of pines. America is the largest producer of Turpentine oil. France and Russia also produce considerable amounts of turpentine oil. The principal source of Indian turpentine oil is Pinus longifolia Roxb syn Pinus roxburghii Sangent (chir pine) grown on the Himalayas hills. The raw material for the production of turpentine oil is the oleorosin which is obtained as an exudate from the pine trees by wounding. The oil is produced by distillation process.

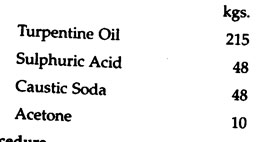

Refined turpentine oil is a colourless, limpid liquid, with a strong characteristic odour and a pungent, bitter taste. Turpentine oil is used for cosmetic preparations and for insecticidal compositions. It is used in metal polishes as a solvent for rubber, fats and oils and as starting material for the production of thymol, menthol, carvacrol, thymoquinone, terephthalic acid and some azo dyes.

PROCESSES FOR EXTRACTION OF ESSENTIAL OILS

Essential oils are produced in various internal and external glands of certain flowers, leaves, barks, wood and roots. Chemically these oils are mixtures, usually very complex, of terpenses, sesquiterpenes, their oxygenated derivatives, and other aromatic compounds. Many contain 2 to 30.constituents covering the entire range of organic materials.

“Aromatic†does not have the usual chemical meaning in the essential oil business. An aromatic chemical in this case, is any compound that has specific, useful odour. As old as the industry itself is the question of whether the plant gets any specific benefit from its essential oils. In some cases, the aroma of the oils undoubtedly attracts certain insect thus aiding pollination, and repel others that might causse damage. But even this obvious function is difficult to prove scientifically.

A number of essential oils appear to have also postulated that they are a reserve food, a means of scaling wounds, or a varnish to prevent too much evaporation of water. Essential oils may be involved in plant syntheses, and perhaps are intermediates that are excreted after they have performed their assigned task in the plant. But despite all the investigations put forward none of them is completely satisfactory.

Market Survey for Essential Oil

Considering the items of agricultural products viz. essential oils and medicinal plants, the role of the Southern Region has been significant. Amongst the essential oils, sandalwood oil contributes to more than Rs. 7 crores out of the total exports of Rs. 92 crores during 1974-75 which incidentally is the highest so far in this group. Another essential oil of importance from the Southern Region is Lemongrass oil, exports of which during 1974-75 were Rs. 0.9 crores. During 1978-79 estimated export of essential oils has been to the tune of Rs. 5.44 crores out of which the Southern Regionâ€TMs contribution of sandalwood oil and Lemongrass oil has been to the tune of Rs. 3.5 crores. It is hoped that the South would continue to play a dominant role in the exports of Essential oils from India, in future.

As regards exports of medicinal plants, the South, especially Tuticorin has played a signigicant role. Barring the exports of Isbagol which takes a large share of the export of medicinal plants, Senna leaves and ponds rank next in importance. During 1978-79 out of the total exports of medicinal plants which amounted to Rs. 15 crores export of Isbagol had amounted to nearly Rs. 8.02 crores and that of Senna Leaves and Ponds Rs. 1.74 crores. During 1978-79 out of the total estimated exports of medicinal plants Rs. 15.00 crores exports from Tuticorin Port alone amounted to more than Rs. 2.00 crores, the major item of export being Senna Leaves and Ponds Rs. 1.74 crores followed by Vinca Rosea.

Thus every sector of industry covered by CHEMEXCIL Council has done considerable efforts to develop its exports and the important role played by CHEMEXCIL does need mention of its services to the member exporters.

The amazing exports developed by this industry set an example for rest of the country, for its will to establish their products in world markets.

A tiny sector amongst S.S.I. mainly concentrated in Bangalore and Mysore, these manufacturer-exporters have demonstrated their genius by establishing exports practically to all the important countries of the world.

At the last Indian National Trade Fair at Moscow in August 1978, they freely distributed sample packs (1.5 Lakhs) and have won the hearts of Russians.

The two major exporting countries are Japan and India, and itâ€TMs creditable for this industry to take about 40% of share where other Indian industries have hardly a share of less than 1% of the world market.

The largest buyers of Indian Agarbattis are U.S.A., Nigeria, Singapore, Saudi Arabia, Kuwait, France, U.A.E., and Yemen Arab Republic.

Cosmetics and toiletries play an important rose in the day to day lilfe of men and women. The day starts and ends with the use of some cosmetics and toiletry or the other beginning from soaps to dental cleaners, shampoos, hair oils, creams, baby powders, facial make-ups and so on. Use of cosmetics and toiletries is centuries old and after bread and butter self grooming is the next most important activity people follow. Hence it is really not correct to say that is a luxury industry and only selected class of society make use of it. In fact, the poorest segment of society make use of it. Even the poorest segment of society also use cosmetics and toiletries in some part of their activities. These products go a long way in grooming our personality and keep us fresh and good looking all the day.

Cosmetics and toiletries in spite of having tremendous potential for growth in local and export is viewed by the government as a luxury and non-priority industry with the result every year rate of excise duty and other taxation is heavily laid. The excise duty is uniformly 60% on cosmetics and toiletries preparations and sales taxes vary between 12% and 15% over and above the Central Sales Tax amounting to 4% for inter State transaction. The incidence of Octroi duty is also high and varies between 2% and 4%. This heavy incidence of these indirect taxes has led to a reduction in production of these items. It must also be noted that the industrial raw materialsm, containers and packaging materials also attract very high rate of excise duty and sales taxes.

The production of cosmetics and toiletries is relatively simple not requiring large scale capital equipment. It requires good understanding of fundamental process on chemistry particularly the emulsion systems and trying out various formulations in the labouratory and carrying out the stability and microbiology tests before the product is marketed. The companies with pharmaceuticals formulation base can easily be geared to undertake manufacture of various cosmetics and toiletries. This is of particular interest to small scale manufacturers whose capital base is limited.

While consumer items need attractive packaging and publicity, even the bulk exports of essesntial oil, aromatic oil and perfumery compounds suffer often from the image of a reliable source of supply.

The total exports of cosmetics and toiletries have increased from Rs. 1.27 crores in 1963-64 to Rs. 11.43 crores in 1976-77 and Rs. 16.00 crores in 1977-78. The estimated exports during 1978-79 are Rs. 13.02 crores. The main items of export from this group of items have been Henna Leaves and Powder, Hair dye, spiritious toilets preparations, Perfumes, spiritious and medicated soaps. It is interesting to notethat the exports of hydrogenated castor oil have recorded an appreciable increase during the year 1978-79 i.e. exports have risen from Rs. 90 lakhs in the year 1977-78 to Rs. 136 lakhs in the year 1978-79.

PROCESSES FOR EXTRACTION OF ESSENTIAL OIL

Almost all essential oils from various sources are extracted by distillation method. There are three types of distillation methods namely:-

- Water distillation.

- Water & steam distillation.

- Direct steam distillation.

With the method called water distillation, plant material is in direct contact with boiling water. Heat is put into the still by conventional means such as an enclose steam coil, steam jacket, or direct firing. The second technique employs a grid to hold the plant material off the bottom of the still. The water level is kept below the grid so that the plant material is in contact with saturated steam only. Direct steam distillation also uses a supporting grid. Live steam, saturated or superheated, is fed into the still below the charge. Distillation has some drawbacks. Some components of esssential oils are sensitive to heat, and the prolonged action of steam in the still can degrade the product. Some constituents dissolve in water, and cannot be easily recovered. Others boil at too high a temperature to be carried over with the steam. Oil from dedicated flowers, such as jasmine, are particularly sensitive to the rigors of distillation ; such flower oils as well as other oils are often isolated by extraction.

Extraction with cold fat, called enfleurage, is the oldest extraction method. It is not widely used now except in the Grass region of Southern France and some parts of Italy. Enfleurage is used with those flowers that continue to give off perfume after picking. The petals are laid at room temperature, over a fat base made up primarily of lard. When the fat becomes saturated with oil, the oil is extracted with alcohol. A variation of enfleurage, also largely out of date now, is maceration or extraction with fat that has been heated to its melting point. It is useful with flowers like the rose which do not give off perfume after harvesting. The oil saturated fat from maceration, called pomade, may be sold as such or treated with alcohol to obtain a more concentrated material is called a floral absolute.

Most modern essential oil extraction plants use solvent system based material such as petroleum, ether or benzene. The key advantage of extraction over distillation is that temperature can be held under 50°C during most of the process. Extracted products, therefore, have a true-to-nature odour that is not matched by distilled counterparts. While this feature is of considerable importance to the perfumer, extraction probably will not replace distillation as the principal means of isolating fragrance, from plant material. A solvent extraction system requires a relatively large capital investment and a crew of trained workers to run it. In contrast, distillation equipment can be simple, portable, and operated without much special knowledge. Moreover, operation costs of extraction are high compared to distillation because of unavoidable solvent losses.

While accurate figures on the overall cost of extraction relative to distillation are not available, the capital investment for an extraction plant is in the order of three times that required for distillation. This is because extraction calls for three separate units â€" the extractor itself, a solvent, recovery still, and a finishing still. For economic reasons extraction is generally limited to higher priced materials such as jasmine and tuberose concretea concrete is perfume material that contains essential oil plus waxes and other retractable plant materials.

Use of solar Energy for Distillation

Keeping in view the steep escalation in the cost of firewood used for distillation of oil from essential oil yielding plants the production of essential oil has somewhat become a costly affair. Small farmers therefore utilise other sources of fuel substitutes such as spent grasses, bagasse and other wastes, which results in lower efficinecy of distillation and oil recovery and moreover the quality of production is also below the average. A pilot plant of a solar distillation unit designed by a research labouratory at the Taimil Nadu Agricultural University Coimbatore has given encouraging results in the distillation of oil from palmarosa grass.

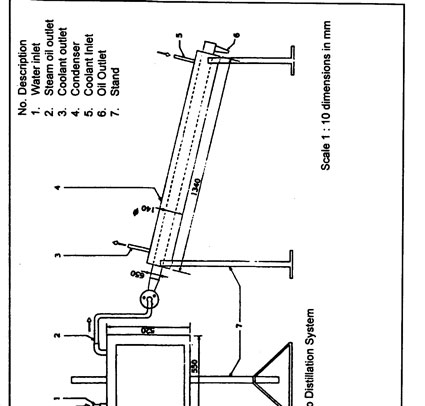

The unit consists of the following sections:

- Solar energy reception unit

- Energy conservation unit

- Distillation unit

- Condensing unit.

The first part consists of a unit in which the solar energy is focussed by using six individual portable reffectors made of plane grass mirrors.

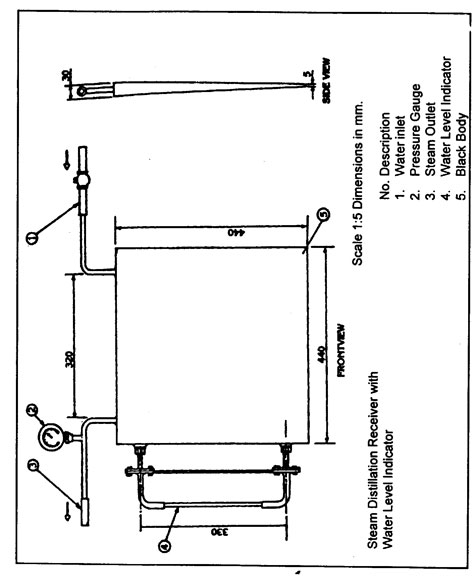

The second portion consists of an energy conversion system with a vertical receiver in which water in the case of steam distillation and water and grass in the case of hydro-distillation are heated. The receiver is placed in an outer G.I. box with a 5 cm gap which is filled with glass wool for insulation. The receiver is fixed to stand which can be lowered or raised to the required level. A absorber coated with black colour absorbs the solar radiation from the concentrator and the water gets heated to 100°C to produce steam.

The third portion of the unit is the distillation unit. For extraction using hydrodistillation the vertical receiver is used to heat the water in which plant herbs are kept. In steam distillation the water in the receiver is heated and the steam produced is allowed to pass in a container in which the chopped herbage is placed.

The fourth portion is the counter flow water cooled condenser of about 130 cm. length where the steam with the volatile components are condensed.

The process of steam distillation using solar energy in the morning usually takes only two hours while the hydrodistillation in the morning hours or day time takes two and a half hours. The time taken by the conventional process is also usually two hours. The results though encouraging provide an ample scope for improving the design of the solar unit so as to suit large scale commerical distillation as well as reduce the cost of production, operation by manipulating the process variables, such as pressure and temperature inside the receiver.

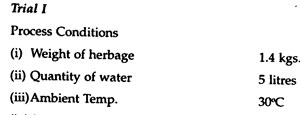

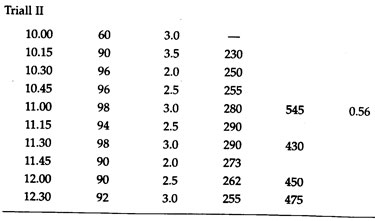

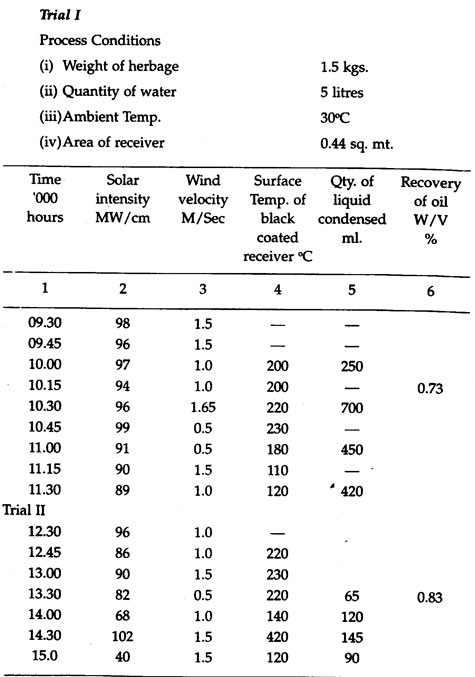

Table 1: Hydrodistillation of essential oil from palmarosa grass with solar energy

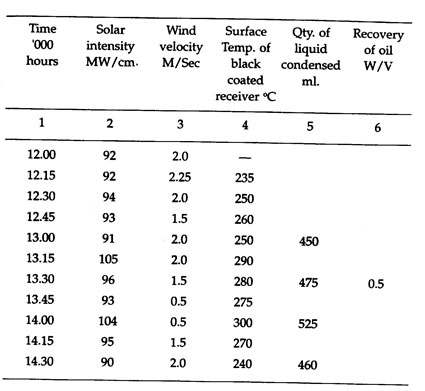

Table 2. Steam distillation of essential oil from palmarosa grass with solar energy.

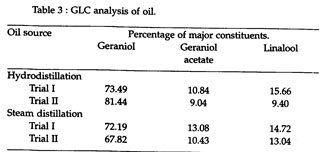

Table 3. GLC analysis of oil.

Other Processes for Extraction of Essential Oils

The other methods of extracting the essential oils are â€"

- Expression Method.

- Extraction by Solvents.

- Extraction of Essential oils in liquid & dene carbondioxide.

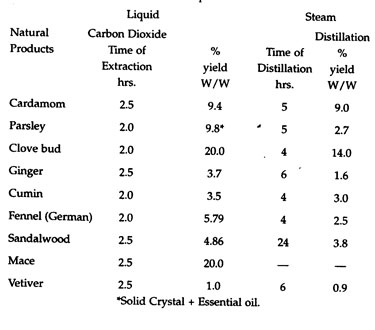

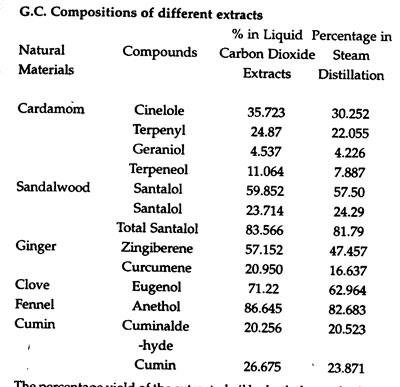

1. Expression Method