Skin-Care Products

Introduction

The technology of skin care is broad and differs from many other cosmetic categories because of the functional nature of many of the products. There are products that primarily have cosmetic effects and products that have very significant pharmacological effects. All products, however, are designed to interact and treat the largest organ of the body-the skin. To understand the need for the category, one must understand the business. The skin-care business is very large worldwide, with total sales of over 10 billion dollars divided between mass and prestige distribution. Mass is roughly 60 and prestige roughly 405. The largest market are Japan, at 3.5 billion dollars, the US at 2.5 billion dollars, and we stern Europe at 3 billion dollars.

Further divisions within the business are products based in sub-categories within the skin-care market. As an example, the US market is 23% hand and body moisturizers, 34% facial moisturizers. 13 % suncare and 24% cleansers (excluding bar soaps). These ratios vary between mass and prestige, and from market to market, depending on national distribution patterns, usage habits and the number of products used by consumers on a regular basis. With the exception of hand lotions, sunscreens and lip protection products, and excluding bar soaps, the market usage and purchase is dominated by women, who account for over 80% of the usage and perhaps 90% of purchase.

Anatomy and Physiology of the Skin

The skin is the largest organ of the body. It is an organ that has diverse functions, including barrier function, protection from radiation, control of body temperature and transmission of stimuli from its abundant network of nerves.

An excellent reference text on the skin is provided by Montagna and Parakkal. This text concentrates on the science of skin, which must be understood as a foundation before products affecting the skin can be appreciated or formulated. Our knowledge of the skin and its function expands every year, therefore it is imperative that one continues to study current literature, in order to remain informed. An excellent examples of the progress of the science is the evolution of the knowledge that the outermost layer of skin, the stratum corneum is 'alive'. It had previously been accepted that the stratum corneum was a collection of dead cells, with no ongoing activity beyond barrier function. It is now known that many functions do take place and may originate in this layer.

In cosmetic chemistry and the business of skin care, we are primarily concerned with the outermost layers of skin (epidermis) and, in particularly those areas that are visible, such as face, hands and legs. To understand the overall anatomy and physiology of the skin, the cross-section shown in Figure 1 should be referred to throughout the following sections.

We are all familiar with our own skin. Closer examination reveals that it is varied in appearance, structure and function in different areas of the body. The skin is generally hairy, except for the palms and soles of the feet. Hair follicles vary in density and functions, for example large terminal hair follicle, on men's scalps and beards, to small vellus hair follicles on womens' faces and are all associated with sebaceous glands.

Epidermis

The epidermis consists of several layers and varies in surface topography and thickness. The epidermis on the soles of the feet and palms of the hands is thickened; on the scalp and face it is less thick, while on the trunk and the interior surface of the limbs it is thin.

Stratum corneum The outermost layer of the epidermis is the stratum corneum. This is the visible layer, and the one on which cosmetic chemists focus most attention. It consists of about 15 to 20 layers of flattened cells (eratinocyles). which become disassociated and ready for shedding or desquamation as they migrate to the surface. These cells are distinguished by not having nuclei or normal cell contents, and were thought to be dead, but they do have function and organization, and they can be controlled and managed.

Stratum granulosum The next layer within the epidermis is the stratum granulosum or granular layer. As cells progress to the surface, they form the characteristic granules of this layer.

Stratum spinosum Beneath the stratum granuosum is the stratum spinosum or spiny layer. This layer of cells is distinguished by a spiny appearance and the presence of desmosomes. This is the area where the intercellular lipid is formed. This lipid material is extruded between the cells of the stratum corneum as they migrate to the surface. The cells are looked upon as bricks, and the epidermal lipids as the mortar which helps hold the cells together. The lipids are similar to sebum, except for a lack of wax esters and squalene, and the presence of ceramides.

Stratum basale This is the innermost layer of the epidermis and is also known as the germinative layer. It is in contact with the dermis. It is in this layer that epidermal cells originate through the formal ion of keratinocytes, which differentiate as they migrate to the surface. This layer also produces langerhans cells, which play a role in the immune system and the body's defense mechanisms. The entire cycle of formation, differentiation, migration and exfoliation irorn stratumbasale to shedding by the stratum corneum takes from 40 to 75 days. The stratum corneum cycle is about one third that of the total epidermis.

Dermis

The epidermis is dependent on the dermis for its source of nutrition. The dermis is a connective tissue that provides a support system for the epidermis. All of the skin's blood, nerves, lymph and external structures, such as hair follicle with sebaceous glands, and eccrine and apocrine sweat glands, are based in the dermis.

Fibroblasts, collagen and elastin The dermis has a fibrous component of various identifiable materials. The primary fibrous material is collagen, with a lesser content of elastin and smaller proportions of other fibrous structures. These fiber bundles and structures form an interwoven network that lends support, flexibility and suppleness to the skin. The source of these fibrous materials, the fibroblast, is the most numerous type of cell in the dermis.

Mast cells Mast cells are the second most numerous cells in the dermis. They are granular in nature and are most numerous near the capillaries. Mast cells participate in the release of enzymes and materials to control function or respond to injury.

Blood supply The blood supply for the dermis is abundant and consists of a complex of arterioles and capillaries that are drained by the venous system. The blood supply does not extend into the dermis. The purpose of this complex network is not only for cellular nourishment, but also for temperature control, as demonstrated by flushing (dilation) and goose bumps (constriction) at opposite extremes of the body's temperature control.

Hair follicles and sebaceous glands The combination of hairs, and their follicles and attendant sebaceous glands is known as the pilosebaceous system. The hair follicle consists of epidermal tissue that extends into the dermis for its biological needs. There it obtains a source of nourishment from an abundant supply of blood, attaches to nerves and in the case of large terminal hairs, has an attachment to the arrectores pilorum muscle. This muscle can raise hairs in response to cold, or emotional signals.

In general, a sebaceous gland is associated with a hair follicle. For the purpose of this review, the activity of the sebaceous gland, and not the hair, will be focused on. The majority of sebaceous glands occur on the head and upper torso of the body, and are only absent from the palms and soles of the feet. Most sebaceous glands associated with hair follicles open inside the pilosebaeous canal. On the face, some large sebaceous glands either associated with fine velus hairs, or without hairs, can open directly on to the surface of the skin. The sebaceous glands form and secrete sebum, a unique blend of lipid materials not found anywhere else in the body. The size, maturity and amount of secretion is triggered by hormonal activity, which peaks in the teen age years. Sebum is synthesized within the sebaceous gland and consists of triglycerides. fatty acids, wax esters, squalene, and cholesterol esters. The sebaceous glands, when active, produce a continuous now of secretion without regard to the condition of the skin and hair, or the level of previously secreted sebum on the surface.

The sebaceous glands are a site for the development of acne. Even although the glands are controlled and enlarge and develop by hormonal activity within the body, acne is dependent on many other factors beyond the development activity of the glands. This will be discussed later.

Sweat glands Two types of sweat glands are present in the human (6). The most prevalent (more than two million] are the eccrine sweat glands, which have a primary function of controlling body temperature. The eccrine glands are also responsive to other triggers such as stress and sunlight. They extend from the epidermis into the dermis and. in the dermis, are surrounded by blood vessels. The sweat secreted by the eccrine system is relatively low in solids, consisting primarily of sodium chloride.

The apocrine glands are found primarily under the arms and associated with the sex organs. They are, like the sebaceous glands, primarily associated with hair folllicle, usually opening into the pilosebaceous canal. These glands are much larger than eccrine glands but. like eccrine glands, originate in the dermis. The sweat produced, much less in quantity than that produced by eccrine glands, is higher in solids and of a more complex nature. It is viscous and milky, and contains high levels of protein, along with cholesterol, steroids and other lipids. It does not have a pronounced odor on secretion, but develops a distinctive odor due to enzymatic activity on the skin. The purpose of aprocrine glands is unknown, but has been speculated to be sexrelated, or a means of identification of communication through odor. This is the function of similar glands in other mammals.

Skin Colour

The colour of the skin and hair is primarily due to the existence of pigment bodies known as melanin. Melanin is produced by the melanocyte cells present in the stratum basale. These melanocytes are present in this basal layer in great abundance and the number does not differ greatly in people with more or less melanin pigment or colour in their skin. Melanin may be produced in either a yellow/red or black/brown colour, and the colour of the skin is determined by the amount and type of melanin produced. Melanin production is increased by exposure to the sun and plays a role in protecting the skin from sunlight.

Test Methods

In addition to a basic understanding of the anatomy and function of the skin, a good foundation and understanding of various tests available for the function of the skin, as well as tests for product performance, is essential. The cosmetic chemist has been aided by many new test methods to help determine performance of skin-care products. These methods vary from in vivo observational or instrumental test methods to a wide variety of in vitro test methods.

Efficacy Testing

The majority of skin-care products are sold to improve the appearance and feel of the skin, and are broadly classified as moisturizers. The condition and appearance of the skin is a function of its softness and flexibility, which is adversely affected by loss of water. Tests for moisture content and moisture transmission, as well as the viscoelastic response, ultrasound techniques, and elecirical properties of skin have been the subject of much study, with the development of increasingly sophisticated instrumentation to show the condition of the skin and its water content. Most of these new methods have evolved to help evaluate the potential performance of products, and are very useful in screening formulations, levels of ingredients and other stepwise formula variables. However, experience has shown that none of the available test methods totally replace in vivo application, professional observation and sophisticated consumer research utilizing both professional, and self- or consumer- evaluation of performance.

In vivo observational tests for moisturizers One of the primary and most valuable in vivo tests used, especially to test hand and body lotions, is the regression test method developed by Kligman [9]. This test is run in a location where the ambient relative humidity is conducive to development of dry skin. Panelists are 'dried down' by washing with a non-fatted bar soap for one week, without use of a moisturizer on the test site, which is either hands or lower lateral legs. The hands or legs are then observed and graded. The test protocol calls for use of product by some panelists, with others acting as non-treatment controls. At various times, during a two-week period, the condition of the skin is evaluated for dryness. flaking and redness. Treatment is then withheld for one week, and the rate of return to a dry condition is observed. This testing yields a good evaluation of the treatment potential moisturizer products and their duration under severe conditions. The method has recently been improved as reported by Boisits et al.

The condition of the face and its response to moisturizer products have also been evaluated by a variety of methods. A widely used methods is the superficial facial line test, developed by Packmanand Cans. This test has been developed for use by trained judges and also by untrained panelists. The standard method utilizes scoring, by trained judges, of superficial facial lines for depth of line in each of four areas in a half-face study. The other half of the face as a non-treatment contrl. Four days long, with no treatment on the first day and treatment twice a day on days 2,3 and 4. The authors also discuss the use of self-evaluation by twelve untrained evaluators, who evaluate superficial facial lines in a similar test method.

Cell turnover testing. A very useful test to determine cell turnover rate utilizes the dansyl chloride test [13], in which dansyl chloride, which fluoresces under a long-wave UV or Woods lamp, is applied to the skin. This material penetrates the stratum corneum to a uniform depth. The cell turnover rate, or transit time, is determined by disappearance of the stain compared to a non-treatment site.

In vivo instrumental tests An in vivo instrumental test that is proving to be of great value is profilometry, which is especially useful in the assessment of the changes to the skin's surface caused by the anti-ageing effect of retinoid therapy on sun damaged skin. Two primary methods are used in profilometry. One method employs replicas and the other uses photographs. Fully hydrated skins such as altered surface characteristics, as measured by both lower peaks and greater distance between peaks. This is also the case with skin that has fewer lines and wrinkles clue to effects other than hydration. In evaluation with a replica, an instrument with a stylus produces a tracing of the topography of the skin, based on a replica produced by denial impression material. With two-dimensional photographs, computerised image analysis techniques are used to review the image.

The gas-bearing electrodynamometer (GBE), has been widely used to evaluate the viscoelastic properties of the stratum corneum. both in vivo and in vitro. More recently computer handling of data generated by this device has improved its utility. The Twistometer device measures resistance to torsion of the skin, as applied by a rotating disc inside an external ring, which acts as a staler. This device is used to evaluate the skin's softness and suppleness. There has been a long history of the measurement of not only the water content of skin, but also the flow of moisture from the skin, which is known as moisture vapour transmission rate (MVTR) or the moisture/water loss or transepidermal moisture loss (TEML). MVTR is a technique that has shown continual refinement. Early papers by Berbe and co-workers outlined theory and practice. Progress has continued to the more recent development of a well-accepted instrument, the Servo-Med® evaporimeter. Most of the work on the direct measurement of water content in skin has utilized an infrared (IR) spectrophotometer. An excellent review is given by Potts.

In vitro testing for moisturizers Many in vitro tests are cited in the literature. An excellent overall review covering both in vivo and in vitro techniques has been written by Salter. A technique for conducting the in vitro moisture vapour transmission rate was usefully outlined by Reiger and Deem. Measurement of occlusivity by these technique is useful and, in general, quite reproducible. The tests consist of the flow of moisture through a barrier, which is often a synthetic film with a transmission rate similar to that of skin. This technique (MVTR) combined with a water-holding technique to measure hydration, or the ability of (he formula or test material to maintain humectancy, is very useful in evaluating of predicting potential in vivo results.

Test methods other than MVTR and water holding capacity have been outlined by Quattrone and Laden [29]. They include scanning colorimetric techniques, scanning electron microscopy (SEM) and biomechanical properties of skin under in vitro conditions. In vitro test methods can be instructive when their correlation to in vivo performance has been established. In the author's experience, a battery of tests and an excellent history of correlation are necessary for the tests to be of predictive clinical value. The problem is that, when in vitro tests are used with excised skin or a synthetic membrane, un-like the human skin, there is a lack of the biological underpinnings of the epidermis, which is anything but an inert, static or dead layer.

In vivo test for sebum An in vivo device for measuring the oiliness of the skin has been developed. This device (Sebutape) is a film that visualizes and traps sebum. The tape can then be analyzed, and total relative sebum amount computed using image analysis. If quantification is not the only requirement, the sebum can be solvent-extracted, gravimetrically analyzed and broken down into component parts. This can be a very useful technique for assessing the instant removal of sebum by cleansers, or the effect on sebum production of various treatments.

In vivo test for cleanser mildness A wide variety of cleansers are available on the market and will be covered within this chapter. Tests for cleansers have focused primarily on testing soap or detergent for-mulations for mildness. In the past, mildness has been evaluated by the Soap Chamber Test. In this test, diute solutions of soaps or test solutions are maintained in a cup held against the skin of human volunteers. The skin is then evaluated for redness, scaling, and fissuring, often against high irrilancy (non-fatted soap bar) and low irritancy (fatted sodiumcocoisethionate bar) controls. A more recent modification of this method calls for a shorter test, and measures the increase in MVTR by a Servo-Med® evaporimetcr. This has shown a close correlation with the longer duration visual assessment technique. The: authors of the Soap Chamber Test cautioned as to the limitations of the test and recommended, in addition to this method, the use of ex-aggerated washing tests, commonly known as forearm wash tests. These methods differ from the Soap Chamber Test in that the Forearm Test adjusts frequency for humidity, while the Flex Test is reported to be unaffected by humidity. For evaluation of facial cleansers of all types for mildness and drying potential, the method outlined by Frosch utilizes half-face testing with realistic use conditions. In order to obtain suitable dryness scores, this lest is best run during periods of low relative humidity. Cleanser tests for efficacy, evaluating soil and make-up removal, as well as esthetic properties and after-cleansing skin-feel, must also be done to obtain a complete picture.

A combination of all these test methods, together with adequate clinical and consumer trial and observation, should enable one to have a great insight not only into the performance of products but, more importantly, as to how and any why products work, and how variations in formula affect performance. This is necessary for the enlightened formula lor.

Formulation

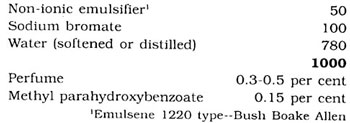

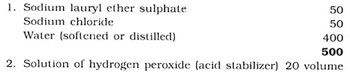

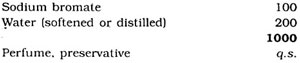

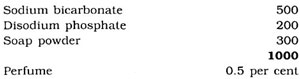

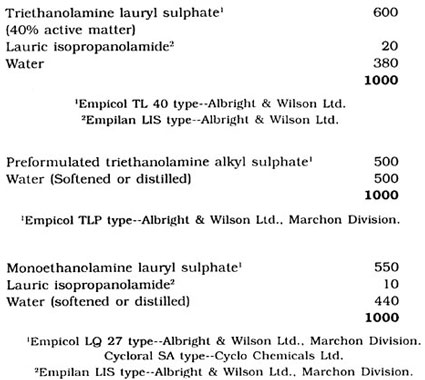

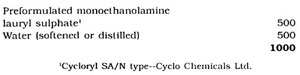

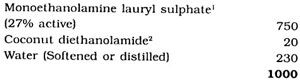

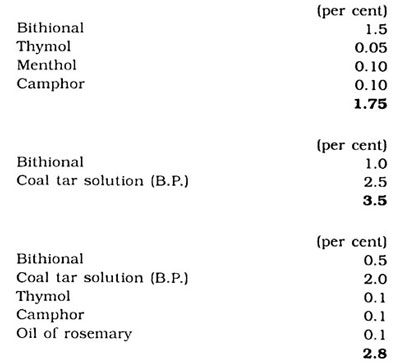

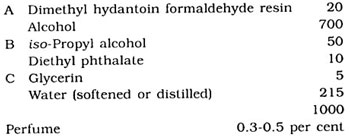

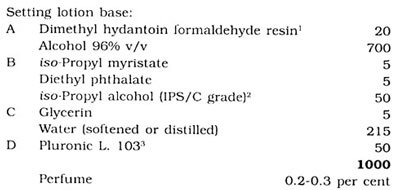

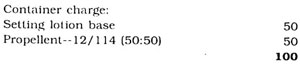

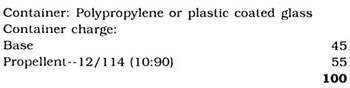

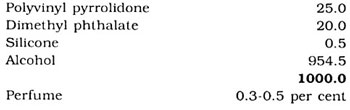

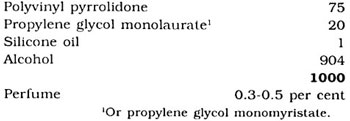

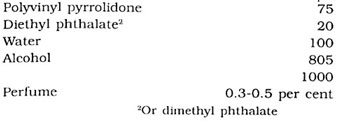

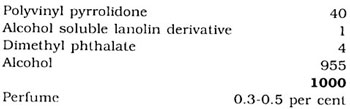

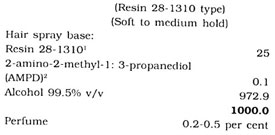

Throughout the remainder of this chapter, formulas will be pre-sented as examples of particular formulation categories. These will be prototypical examples, taken from experience or from suppliers. They are only intended to give the formulator a general idea of typical formulas and constituents by category, and are neither tested for per-formance or stability, nor ready for the market. This would require considerable experimental work and testing. In addition, many new raw materials with functional and emotive benefits are available from raw material suppliers and should be reviewed on an ongoing basis during development.

Formulation is an art and a science, and requires close attention to detail and trial and error before proficiency becomes routine. The formulator must, first of all, make a product that has characteristics required by the ultimate consumer of the product. These requirements will vary depending on the specific usage, demographics of the consumer, expectations, claims, class of trade and packaging. The formula must be fit for use by the consumer at any point during its expected shelf-life. During formulation, this requires adequate stability trials and examination for microbiological integrity. It must also be possible to make the product using reasonable manufacturing equipment on a scale that is appropriate for anticipated demand. Further areas that are becoming increasingly important are safety under all conditions of use and potential misuse, and regulatory and environmental acceptability. These aspects of formulation will be discussed in the following sections.

Formula Information

Much formula information, from a variety of sources, is available to the cosmetic chemist. Excellent background information and general formulation information may be obtained from the several reference books kept in most industrial libraries or large public libraries. The nature of these texts will generally give excellent historical data, but, the most up-to-date formulation data can be found from other sources. The first of these are the many periodicals that are published for the technologist in the cosmetic industry. These periodicals often have formulation articles and review articles covering a specific category, and also provide another valuable resource, i.e. identification of, and advertising from raw material suppliers. Raw material suppliers frequently publish information on starting formulas and give specific help with formulating. They are a rich source of ideas and guidance and some will even provide formulation assistance in their own laboratories. One must keep in mind, however, that the goal of the supplier is to sell the raw material.

An excellent starting point for the formulator is to review listed ingredients on the labels of finished formulas of market leaders' target products sold where ingredient disclosure is required, such as in the US where all cosmetic products must list all ingredients in descending order of content. It is helpful to review these ingredient lists, perhaps assay for a material or two. and speculate on the formula based on other sources of starting formulas. An assay for water, total lipid material and, if incorporated, humectant. will give much information about a formula that has already proven to be acceptable to consumers. The ingredient list in the US also uses accepted nomenclature from the US trade association, the Cosmetic Toiletry and Fragrance Association (CTFA) in its Cosmetic Ingredient Dictionary. This in excellent reference, as it lists not only the generic CTFA name, but provides technical information on the raw material, and lists suppliers of it. Another good source of information is to join and participate in local cosmetic chemists' organizations and attend their meetings. Seminars are held frequently and are attended by suppliers to the industry.

Consumer Testing

Consumer testing and input is a must for the formulator. This should take place before and after product development. Once a prototype formulation has been developed, determined safe for use by consumers, and adequately preserved, it should undergo initial testing for consumer acceptance. Most commercial organisations have standards for consumer testing, which are usually organized by the marketing department. It is, however, very helpful to the formulator to seek consumer input at all stages during development of a product, for instance to develop an enlightened view of consumer requirements by talking to target consumers about their needs before development is initiated. This can be done informally or formally, either one-to-one, or with groups of consumers. Another useful technique is to give representative consumer users and non-users of the leading product in a category, an unidentified sample of the market leader to use for a week. Following this, the way in which the consumers used the product, the results of product use, and the likes and dislikes can be discussed on an open ended basis. Attribute comments and areas of dis-satisfaction with the target product should be noted. The information can then be used as a base line for later examination of a developed prototype. Another useful technique, known as a sequential monadic. is, at the next stage of development, to have target consumers use both the prototype formula and the market leader of competitive bench-mark product. Half the panel first uses the prototype for a period of time, and then uses the competitive benchmark product or market leader: the rest of the panel uses the products in reverse order. With this technique, a good comparison of the prototypes performance versus the benchmark product on attribute by attribute basis is obtained. At this stage, testing should be on an unidentified basis, since the requirement is for performance and attribute data as a guide to formulation. In larger concerns, testing of finished products on an identified basis with advertising or concept, is usually handled by the marketing or market research department. It is possible, however, for the cosmetic chemist formulator to have this work done for them by independent market research firms, or by advertising agencies.

Stability testing

Stability testing is done to ensure that a developed product will be fit for use during its expected life. Stability testing should be done early in the development cycle to remedy any problems before final testing. A well-run stability trail can provide much information about a product in a relatively short period of time. Prototype products in packaging, representing the ultimate trade package material, can be placed at ambient, and elevated (e.g. 37°C and 45°C) temperatures, refrigerated and cycled through freeze/thaw cycles, and placed in high humidity chambers. During these trials, testing should focus on attributes most important to the product's performance, or on the integrity of any active ingredients. In addition, there should be physical testing, for example pH and viscosity, chemical content of active ingredients, water content, etc. The formulator must not overlook attributes relating to consumer perception, such as fragrance, colour, rub-in characteristics and appearance. Two or three months of successful elevated temperature testing and three or four freeze/thaw cycles will usually indicate that products will have an adequate shelf-life. It is important, however, to continue testing for longer periods at ambient temperature, to obtain an understanding of the product's ultimate shelf-life. Further testing whenever changes are made to the supply of raw materials or to the formulation is essential.

Microbiological Testing

During the development phase, close attention should be paid to the microbiological integrity of the formulation. Professional advice should be sought from a well-trained industrial microbiologist. If this is not immediately available, input and guidance on preservatives from the suppliers' staff and consultants should be sought. Suppliers will often have more than one preservative and can make recommendations about particular types of formulation. Another method of finding appropriate preservatives is to review ingredient labelling on similar types of products that are available from reputable manufacturers and which have similar constituents, pH and package types. This, coupled with a microbiologist's or a preservative vendor's input can often give several trial systems. Finished products are usually tested using a challenge technique. If this essential testing is not available in-house, a qualified contract lab can assist. The test involves adding large numbers of a variety of organisms to the product and checking the ability of the product to reduce them to an acceptable level. To ensure that the product retains its ability to remain preserved, adequacy of preservation should also be checked during stability testing.

Manufacturing Trials

A product cannot be a commercial success unless it can be made with large-scale equipment, therefore as soon as a prototype develops beyond its earliest stages, and at all subsequent stages of development, manufacturing should be considered. If an engineering group is available, it should be consulted, and should participate in a laboratory batch of the new product on a bench scale. This, if possible, should compare the compounding of the product, heating and cooling cycles, phase additions, etc., with a similar type of product that is already being manufactured. Any significant deviations from norm should be noted and investigated for possible change or for special attention during scale-up. Scale-up can represent large changes in batching times, time at temperature, etc. It is advisable to scale-up in increments, preferably not greater than 10 x at any stage. For instance, going from a 1 kg lab batch to a 10 kg lab batch, then to a 100 kg pilot batch and 1000 kg manufacturing batch would be a logical sequence. Any significant problem at each stage should be investigated and, at the very least, abbreviated stabilities should be run with product from each stage.

When final manufacturing is initiated, the development chemist or engineer should stay with the process until several batches have been made without problem. It is helpful, during the life of the product, to return to manufacturing and continuously improve the process. Time should be spent with veteran compounders, as they often have great insight into how a process can be improved. Product from first production trials should also be put through a complete stability test, comparing results to those obtained during development, and addressing any problems that may occur.

Safety Testing

The product must be safe under all conditions of use and potential misuse. Safe products arise from a combination of careful formulating, good background data and adequate testing. A review of materials used in products for similar purposes is an excellent place to start. Most successful commercial products have been adequately tested and have a history of safe usage. Safety data for each raw material should be available from its manufacturer and should be reviewed. In the US, the CTFA has a Cosmetic Ingredient Review, which evaluates materials and also lists safety data for materials that have been reviewed. After a thorough background check, finished produces should be tested through a competent third party. Many testing companies not only do safety testing, but also recommend appropriate testing that should be done for the class of product that has been developed. It is often useful to solicit testing protocols from two testing companies, asking them to explain and justify each test they recommend. It must be remembered, however, that they can only make enlightened recommendations based on input. Divulging as much information as possible at this stage, will give better, more appropriate testing input, and insight into possible untoward reaction.

After adequate clinical testing has been completed, and during all stages of consumer trial, it is important to check for unexpected reactions or patterns of misuse, while carefully extending exposure. Careful attention should be paid to reported reactions from usage or misusage situations. After launch, there should be mechanism to check on reported reactions to determine if, on a broad exposure, these levels are higher than one would expect for the category, category adverse response reporting data is available from the US Food and Drug Administration (FDA), and often from local trade associations.

Regulatory and Environmental Requirements

Regulatory requirements vary greatly from country and can be ascertained by direct contact with the local regulatory authority. Excellent advice can frequently be obtained from local trade a associations, who have insight into not only what is required by law or regulation, but also what is acceptable and expected. Membership of trade associations and participation in their activities is invaluable.

Environmental restrictions or concerns are often more elusive, or more difficult to determine. Trade associations, trade publications and local groups of cosmetic chemists can be of great help. Many companies also seek advice from consultants who are experts in this area, or, in some cases, have direct meetings and constructive dialogue with leading environmental groups. The person responsible for developing a product or formula should accept total responsibility for the product, and care and diligence should be exercised throughout every aspect of product development.

Skin Cleansers

Skin cleansers constitute an important segment of the skin-care market. Cosmetic chemists are usually involved in the facial cleansers in forms other than bars. This, however, overlooks a large portion not only of the overall market, but also of consumer's usage patterns. Most consumers use bar products, either based on soap or synthetic detergent (syndet), for skin cleansing. All other cleanser products represent other types of usage and vary greatly from market to market depending on patterns of make-up usage, cleansing habits, etc.

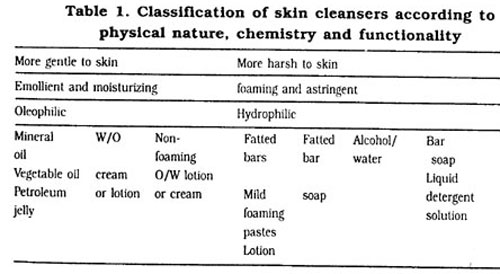

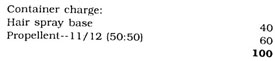

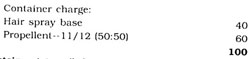

In order to properly classify cleansers, it may be helpful to put them on a grid, roughly related to their physical nature, chemistry and functionality, and ranging from products that are anhydrous oils, at one end of the spectrum, to soap and water at the other (Table 1). Various product types have different functions and, while they have advantages for a specific condition or soil, none is universal. Most consumers use more than one type of cleanser, so an understanding not only of chemistry and formulation, but also of consumer usage patterns for their needs in a specific market or market segment, is key.

When classifying cleansers, the various soils on the skin must be considered. Soils come from a variety of sources, but can be classified broadly as oil-soluble, water-soluble and insoluble. Sources for oil-soluble soils can be sebum, residue from moisturizers, or waterproof make-ups. Water-soluble materials may also be residue from make-up or moisturizers, soluble skin oils, soils, and soluble grime. Insoluble materials are represented by dead cellular matter, make-up pigments or, in hard-water areas, precipitated metallic soaps.

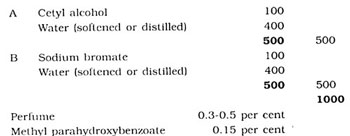

Anhydrous Oily Cleansers

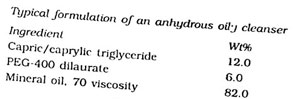

The first category of cleansers is the most oleophilic group. Mineral oil, petroleum jelly, vegetable oils and esters are useful as non-drying skin cleansers for removal of waterproof make-up and oils-soluble soils. The disadvantage of these cleansers is that they are not readily rinsible and often have poor cosmetic and esthetic characteristics. More modern versions incorporate moderate to high levels of esters or gentle oil-soluble surfactant materials to make the products Jess greasy, more pleasant and, in some cases, rinsible. In addition, some formulations are thickened to form gels, which are easier to spread on to the skin and can be tissued off.

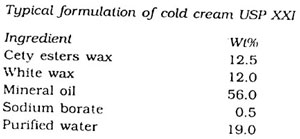

Water-in-Oil Emulsions: Cold Creams

The next category of products are water-in-oil (W/O) emulsion cream and lotion formulas, typified by cold cream. Cold creams are referred to as W/O emulsions but, during processing and usage, are more complex water-in-oil-water (W/O/W) emulsions, or mixed emulsions. The partial or mixed external oil phase of these mineral oil/ bees wax/borax systems dissolve oil-soluble materials and, because of the oily external phase and the beeswax/borax soap at the interface, they are able to solubilize, wet out and transport soil and waterproof make-up. Cold creams are generally not rinsible, are considered greasy and inelegant, and are tissued off the skin. They leave behind a film that has proven moisturizing characteristics. Classical cold cream formulas set the standard for mildness to skin and eyes. In recent years, some rinsible cold creams have emerged. These are cold cream and similar bases to which non-ionic emulsifiers have been added with an increased water phase. These rinsible systems then become oil-in-water (O/W) emulsions. They are not as satisfactory for a waterproof make-up removal, but are rinsible and more cosmetically elegant.

Procedure: Reduce the cetyl esters wax and the white wax to small pieces, melt them on a steam bath, add the mineral oil, and continue heating until the temperature of the mixture reaches 70°C. Dissolve the sodium borate in the purified water, warmed to 70°C, and gradually add the warm solution to the melted mixture, stirring rapidly and continuously until it has congealed. Pour into jars 50°C and cool.

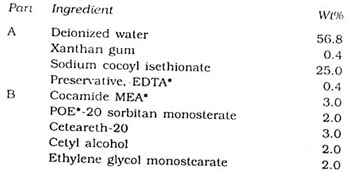

Oil-in-Water Emulsions: Cleansing Milks

Non-foaming O/W emulsions with greater than 50% water phase typify the next category of cleansers. These products are typically referred to as cosmetic milks. The primary cleanser and emulsifier is often a TEA*/fatty acid soap, or a detergent such as sodium cocoylisethionate supplemented by anionic or non-ionic emulsifiers. Cosmetic milks are skin-friendly and have many similarities with O/W moisturizing lotions. However, they differ from moisturizing lotions in that they generally have less water in the water phase, excess TEA fatty acid, and higher levels of a secondary emulsifier such as self-emulsifying glycerol monosterate. Significant levels of mineral oils or esters may also be incorporated to ensure adequate levels of solubilization of oily materials without reducing rinsibility.

TEA. triethanolamine; EDTA. ethylene diamine tetraacetate; MEA, mono ethanolamide; PEG, polyethylene glycol; POE, polyoxyethylene.

Procedure: Dissolve xantham gum in water; heat to 65°C. Add sodium cocoyl isethionate, preservative, and EDTA. Premix part B and heat to 65°C. Add B to A with good mixing: then cool to 45°C. Add fragrance

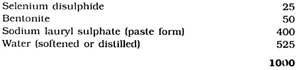

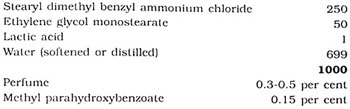

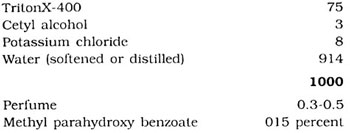

Fatted Mild Syndet Foaming Bars and Cleaners

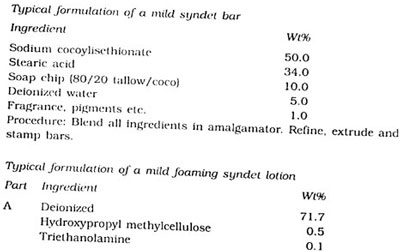

The next category is differentiated because of a foaming characteristic. This is the category of fatted syndet bars and gentle fatted foaming pastes and lotions. These products have good wetting properties but, when used in soap chamber or flex washing studies, are significantly more gentle than fatted soaps, detergent solutions or non-fatted soaps. They occur as bars (fatted sodium coco isethionate, as pastes based on fatted built mono alkyl-phosphates. and as pastes and lotions based on fatted and built sodium coco isethionate. Recent additions to this range of gentle foaming cleansers have been lotions based on sarcosanate surfactants, with high levels of glycerol. protein, and fatty materials to ensure a mild effect. Due to their gentle nature on the skin, mild bars, foaming pastes, and lotions are becoming more important on a world-wide basis.

Procedure: Disperse the hydroxypropyl methylcellulose in water. With mixing, add the triethanolamine to initiate hydration. Begin heating to 65°C. Add the part B ingredients. Premix part C; heal to 65°C. Add part C to the batch with good mixing. Cool to 45°C; arid fragrance.

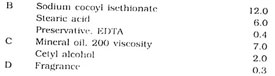

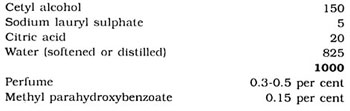

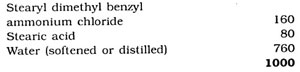

Super Fatted Bar Soaps

Fatted bar soaps have greater cleansing characteristics, with iess skin residue than fatted and build mild detergent pastes and lotions. The formulations contain varying amounts of falty acids or other fatty or moisturizing materials to decrease their aggressive behaviour on the skin. This results in a non-taut skin-feel upon rinsing, and less damage to the skin.

Procedure: Blend all ingredients in an amalgamator. Refine, extrude and stamp bars.

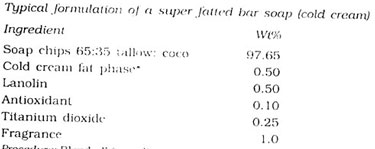

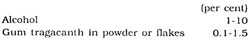

Astringents/Toners

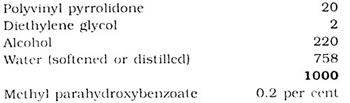

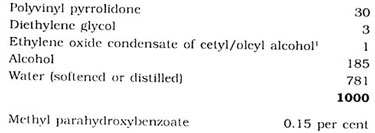

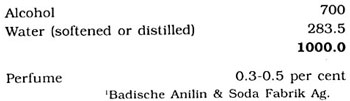

Astringents and toners are a class of skin cleansers that have a special use and very specific formulations. They are hydroalcoholic solutions with an alcohol content from 20-70%. The products with lower levels of alcohol are developed for sensitive skins, while those with higher amounts are for oily skins. Astringents and toners often contain small amounts of emollients or humectants to decrease their defatting of the skin. They are generally used by oily-skinned consumers or teenagers as a supplement for cleansing and acne treatment. They are often the last cleansing step in a ritual to make to make the skin very clean in a preparation for the use of a moisturizer.

Procedure: Dissolve menthol in alcohol. Add fragrance, water and other ingredients. Blend at room temperature.

Bar Soaps

The final category in Table 1 consists of the minimally fatted or non-fatted bar soaps. These coco/tallow soaps are excellent cleansers, but can, if used excessively, irritate the skin. They enjoy considerable usage among consumers as part of an everyday cleansing ritual and, on a worldwide basis, are the most commonly used cleanser product.

Procedure: Blend all ingredients in amalgamator. Refine, extrude and stamp bars.

Participate Scrubs

A speciality category not shown in Table 1 is the creams, which contain particulate materials. These products are often O/W emulsions (if non-foaming) or gentle pastes (if foaming). They contain particles of polyethylene or other inert materials such as ground seed-husks. The purpose of these paniculate materials is to remove loose flakes of stratum corneum and to polish the sin. Interesting research by Loden and Bengtsson indicated that the effect of scrubbing with a particular scrub can be helpful if there is a need to remove a layer of stratum corneum. However, excessive use should be cautioned as, due to their mechanical action, they can be irritating.

Procedure:Heat A to 70°C. Meat part B to 75°C. Add part B to part A with agitation and cool to 40°C. Add part C and mix thoroughly.

The selection of cleansers and their constituents requires extensive testing to ensure suitability for use. The Coal should be to remove soils and make-up with minimal damage to the skin. An interesting approach to the selection of surfactant materials and products is out-lined by Komp, utilizing the Duhring Chamber Test, as well as the antecubital washing test. As well as these exaggerated tests, it is very important to follow prototype formulation with controlled in-use testing for soil and make-up removal, and consumer evaluation use testing.

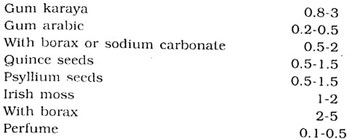

Moisturizers

Moisturizers are products that, are usually emulsions, either O/W or W/O. There are two principal forms of these products: (i) semi-solid emulsions, known as creams: and (ii) flowable emulsions, known as lotions. Moisturizing products are differentiated not only their emulsion type and/or physical form, but also by their functional use. For the purpose of this discussion, all-purpose creams, hand and body lotions and creams, facial moisturizing lotions, and facial 'night' creams. will be considered.

The purpose of moisturizing products is to restore and maintain the skin in a good-looking, fully moisturized condition. To maintain this condition, the stratum corneum must be in a fully hydrated condition that allows flexibility and elasticity. Early work by Middleton and Alien and a review by Idson, show the relationship between water content in the skin, as affected by the temperature and humidity. In most products, this moisturization is accomplished by a combination of hydrating by water followed by the actions of occlusives and humectants. Emulsion products of either O/W or W/O break down when rubbed out on the skin, and add water from their own composition to the surface layers of the stratum corneum. This hydrating effect by water accounts for the instant appearance benefits, including reduction of visible dryflakes and chapping. Less-immediate ef-fects occur through occlusivity and humectancy.

Occlusivity occurs when the transepidermal water loss is slowed through reduction of the moisture vapor transmission rate. Many fatty materials reduce the MVTR. Typical of these materials would be petroleum jelly, mineral oil. vegetable oil, silicone oils, waxes, fatty acids, alcohols, and esters of mineral, animal or plant origin, as well as many synthetic oily materials that are available to the cosmetic chemist.

Humectancy is a separate but related phenomenon, in which materials that have an affinity for water: (i) help bind water to the skin; (ii) resist evaporation from the skin: or (iii) under certain circumstances. attract water to the skin.

Typical of these materials are glycerin, sorbitol, sodium lactate and sodium pyrollidone carboxylate (the skin's naturally occurring humectant. Such humectants have been shown to be valuable not only in hydrating the stratum corneum, but also in improving the elastic modulus and stress relaxation modulus, thus altering the viscoelastic behaviour of the stratum corneum. Extensive experimentation with glycerine has shown that it moisturizes dry skin in a dose-related relationship dependent on the concentration of glycerin. It was postulated that the water glycerin mixtures on the skin also assist in plasticizing the stratum corneum in a less than transient manner. Middleton found that lactic acid was absorbed by the stratum corneum and that increased extensibility was retained by the stratum corneum.

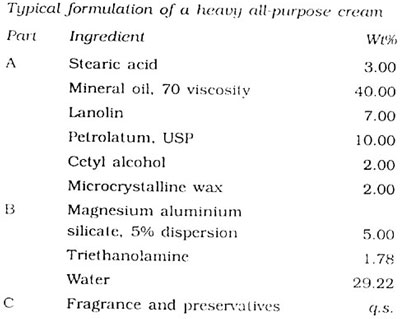

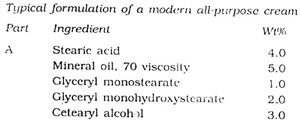

All-Purpose Creams

All purpose creams are typified by a VV/O emulsion or by high oil content O/W emulsions. These products are for general face and body usage and generally have a heavy consistency and significant drag on rub-out. In addition, a small amount of product is able to cover a large area. Many all-purpose creams contain from 30-70% oil phase, resist wash-off, and are excellent protective as well as treatment products. They represent a very significant percentage of the European mass moisturizer market, and are often sold in flat packs (tins) or tubes. Performance characteristics and testing should focus on tests to maximize a reduction in the MVTR, resistance to wash-off and a prolonged improvement to the skin, as demonstrated by regression analysis. Lighter weight, more modern products are, however becoming popular.

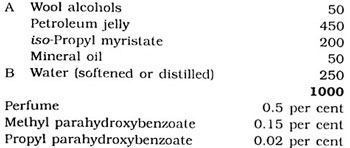

Procedure: Heat part A and B to 70°C. Add part B to part A. mixing continuously. Mix and cool to 35-40°c and add part C. Continue mixing until dispersion is complete. Adjust evaporation losses with water.

Procedure: Heat parts A and B separately to 70°C. Add part A to part B with good agitation. Mix to 35°C and add part C. Continue mixing until dispersion is complete.

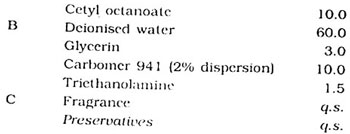

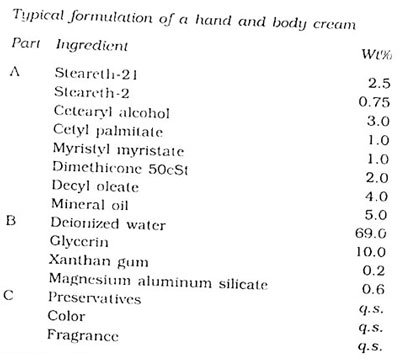

Hand and Body Lotions

Hand and body lotions are generally O/W emulsions, with typical lotion products containing 10--15% oil phase, 5-10% humectant, and 75-85% water phase. They are characterized by easy flow and pumpabilily. fast rub-in, and a lack of stickiness after rub-in. Most of these products are sold in bottles with or without pumps, or in tubes. Their primary performance characteristics are their ability to instantly hydrate skin and to relieve dry skin symptoms. In addition, they should have excellent profiles in MVTR reduction and prolonged improvement to the skin as shown by regression analysis.

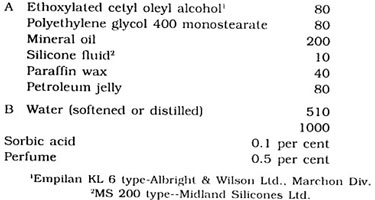

Procedure: Heat parts A and B separately to 70°C. Add part A to part B with good agitation. Mix to 35°C and add part C. Continue mixing until dispersion is complete.

Hand and Body Creams

Most modern hand and body creams are O/W emulsions with greater levels of oil phase and possibly higher humecant levels than lotion products. They generally contain 15-40% phase and from 5-15% humectant phase. These products are easy to apply have a reasonably fast rub-in, good esthetics, and often resist wash-of. They are typically sold in jars or tubes. Their performance characteristics are similar to hand and body lotions, often with the added benefit of more resistance to wash-off.

Procedure: Heat parts A and B separately to 70°C. Add part A to part B with good agitation. Mix to 35 C and add part C. Continue mixing until dispersion is complete.

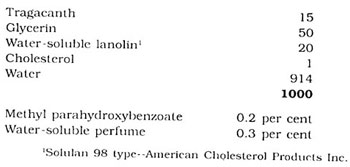

Facial Moisturizer Lotions

In terms of esthetics, facial moisturizer lotions are very different from hand and body lotions. They contain occlusive agents and humectants at the lower concentration levels of hand and body lotion formulations. Great attention is paid to quick-breaking, instant-ab-sorbing products with no greasy after-feel. These effects are obatined by the use of emulsions that break down quickly, dry to a matte finish, and prize light emollients such as esters and fatty alcohols and, where appropriate additives such as volatile silicones. Performance characteristics are good moisturizing capability, the ability to reduce MVYTR rates, and also an immediate and a short-duration effect on superficial facial lines. Visual peformance effects and esthetics are key factors in successful products.

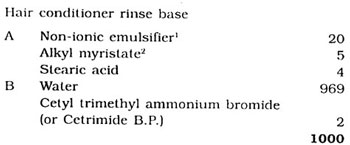

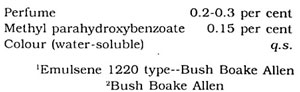

Procedure: Mix all of part A except the triethanoamine. After all of part A is dispersed add TEA. Heat parts A and B to 70°C. Add part B to part A with good agitation. Mix to 35°C and add part C. Continue mixing until dispersion is complete.

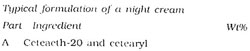

Facial Moisturizer Creams: Night Creams

Facial moisturizer creams are often sold as night creams or heavier duty moisturizer products than their lotion counterparts. They generally have higher levels of occlusive and humectant materials (nan facial moisturizer lotions, but are formulated (with esthetics as a principal factor) using lighter emollients, quick-breaking emulsions, and controlled levels of humectant materials. Additives such as volatile silicones are often added to improve rub-in, break and a non-greasy after feel which, together with a matte finish, are key esthetic features. Performance characteristics are excellent moisturizing capabilities and a good effect on superficial facial lines.

Procedure: Heat parts A and B separately to 70°C. Add part A to part B with good agitation. Mix to 35°C and add part C. Continue mixing until dispersion is complele.

Anti-Ageing Products

The emergence of new technology with proven performance to reserve damage from photoageing necessitates a separate section on anti-ageing products. Many such products are sold, but prior to discovery by Kligman of the effect of retinoic acid on photodamage. and patents issued to Van Scott and Yu on a-hydroxy acids, these products had primarily cosmetic benefits: that is. complete hydration of the skin, a return of suppleness, the reduction of superficial facial lines and. at times, a masking effect, givng lines a more youthful, albeit, transient. improved appearance.

Ageing is well understood and. although much can be done in the laboratory to affect cellular vitality. or to affect the overall longevity of laboratory animals, the human species has not materially advanced in its maximum age as proposed in the original theories of Hayflick and Moorehead. A more optimistic review by Puglese, both of ageing and of events within overall cellular mortality, is of interest and suggests that a proper understanding of the entire ageing process is the key to effecting changes in it. This review offers many areas of interest to the cosmetic chemist. Ageing results in subtle and not so subtle changes in the appearance of the skin. It is probable that many of the effects seen on the skin with ageing are an indirect result of the decrease in the blood supply to the dermis. The number of sebaceous ducts and the level of secretion from them also decreases, however, many of the remaining ducts increase in size. An excellent review of these changes in physiology and pathophysiology by Gilchrest is worth reading in order to understand the substrate in question.

Manifestations of ageing that are of primary concern to the cosmetic chemist are wrinkles. These lines, which become more pronounced with age, especially on the face, are caused by a shrinking of the superficial muscles which have their points of insertion in thedermis. The facial exprssion muscles are the first areas to change with age. They also develop the deepest wrinkles. As they lose superficial mass, thinning of the epidermis and a loss of collagen and elastin are apparent. These all contribute to the visible process called ageing. As yet, it has not been possible to affect this frank, deep cellular ageing. One reason is that there is nothing histological to differentiate the cellular structure of a wrinkle from that of a non-wrinkled epidermal area. An excellent review on this entire subject is provided by Wright and Shellow, who studied the histology of deep wrinkles and adjacent non-wrinkle areas.

Advances are continually being made to show improvements in ageing of photodamaged skin, due to retinoid and retinoid-like effect, more recently demonstrated by a-hydroxy acids and related compounds. Several natural physiological vitamin A or retinoid effects that are known to be ongoing in the dermis are dermal deveopment, collagen synthesis, hyaluronic acid synthesis, DNA content and epidermal protein expression. Since these factors are in part, controlled by vitamin A and its derivatives in healthy skin, it has proven worthwhile to seek profound effects such as those demonstrated by topical treatment of retinoic acid. Achieving a retinoid effect is not possible by simply adding vitamin A or another retinoid to a cosmetic formula. Followng topical application, the effective drug must be available to the dermis and epidermis, without untoward side effects. Recent work with the hairless mouse model has correlated a dose response to increasing levels of retinyl palmilate in a suitable cosmetic preparation. This response from topical treatment resulted in an increase in protein and collagen synthesis, and in DNA content, together with a thickening of the epidermis. Prior work with a topically applied retinoid has shown accelerated dermal repair to UV damaged dermis, due to increasing regeneration of connective tissue. Emerging work has shown quantifiable effects on human photodamaged skin, and significant biochemical changes in the hairless mouse model, due to topical application of a common cosmetic retinoid. This, coupled with the ability to increase cell turnover from use of a cosmetic product, the reduction of superficial facial lines through new and improved materials and mechanisms, and the 'plumping' of the epidermis by occlusive of or humectant agents can, in theory be combined to give excellent visual anti-ageing results.

Both Kligman and Van Scott discuss the effect of both retinoids and a-hydroxy acids on photodamage. That photodamage has a profound effect on the appearance of ageing of the skin, is now well understood. Damage that can manifest itself as ageing, stems from the effect on the elastic fibres that provide smoothness and suppleness. Evidence that these changes can be reversed was demonstrated by Kligman et al.

Recently, a-hydroxy acids, primarily lactic and glycolic, have entered the market place in many skin-care preparations. Smith has demonstrated various effects of these materials and has compared their efficacy. Derivatives of a-hydroxy acids have also been marketed.

A growing problem is whether or not retinoid-like materials are drugs. In the US, and increasingly throughout the world, courts and regulatory bodies are telling us that if a product contains a 'drug', it clearly is a 'drug'. Even if it docs not contain what has been previously classified as a drug, but alters the structure or function of the human body, ii may well still be regarded as a drug. In the US. products containing retinoic acid are classified as drugs and are only available on prescription allowed to be used under the supervision of a physician. At the present time, such products are cleared for use only in the treatment of acne, but are being mis-prescribed by many physicians for treatment of photoageing and its associated derma! damage. They are not without side effects, including significant levels of irritation in some patients.

The status of products claimed to possess anti-ageing, and other properties has recently come under scrutiny by the US PDA. The PDA has issued several regulatory letters to companies requesting them to stop making drug chains i.e. "...altering the structure or function of the body." Most of these regulatory letters have been resolved by the companies modifying their claims following negotiations with the PDA. One company has. however, initiated suit over this issue, which will no doubt be decided in the courts. A review of performance claims for skin-care cosmetics, and the basis of US regulations, was written by McNamara [66]. In this review, the legal basis for the distinction between drugs and cosmetics, based on both claims and ingredients, is discussed.

Anti-ageing products have been marketed by the cosmetic industry for many years. Successful new products were often launched by interesting claims such "penetrates 21 cell layers, "speeds up cell turnover" or "enhances overnight repair at a cellular level. However, although these products did have performance characteristics, proven by new biophysical tests that were optimized in the product, they did not truly change the ageing process. The proven ability of retinoic acid to reverse photodamage has now altered this situation, and true pharmacological effect from topically applied products is now a reality. The successful formulator and marketer will have to keep with this rapidly evolving and most exciting area of science.

Sunscreen Products

Sunscreen products form an important sub-class of skin-care products. In order to have a good understanding of these products, the chemist must first understand the physics and pharmacology of solar radiation, and its effect on the body.

Solar Radiation

Skin damage, and the development of products that help prevent it, require an understanding of the ultraviolet spectrum of light. The ultraviolet spectrum of concern is between 200 and 400 nanometers (nm) and, in practice between 280 and 400 nm. The ozone layer around the earth absorbs the shorter wavelengths, therefore the important wavelengths are UV-B (280-320 nm) and UV-A (320-400 nm). The penetration of the skin by ultraviolet radiation depends on wavelength. As the wavelength increases from 200 to 400 nm, the penetration also increases. Consequently. UV-B penetrates (depending on the thickness of the skin in the area of the body irradiated) into the upper layers of the dermis, whereas the longer wavelengths from UV-A penetrate deeply into the dermis. Due to the variable thickness of the skin on various areas of the body, some areas are more susceptible to sunburn and photodamage (ageing) than other areas.

The immediate symptom of excessive UV-B exposure is sunburn. This is caused by a reaction of UV-B radiation with an absorbing material within cells. This absorbing material has been shown to be DNA, which is then depressed prior to cellular propagation. The ability to penetrate varies greatly according to wavelength, with small percentages of UV-B penetrating to the capillary system in the dermis at lower UV-B wavelengths, compared to roughly 50% at its greatest wavelength (320 nm). UV-B wavelengths, compared to roughly 50% at its greatest wavelength (320 nm). UV-B, however, also stimulates the dermis to form melanin by a complex series of reaction that stimulate melanocytes to trigger tyrosine in a multi-step reaction to form melanin. For this reason to occur, the skin must be stimulated by a dose of UV-B, close to the dose that causes redness. On excessive exposure to UV-B close to the dose that causes redness. On excessive exposure to UV-B (beyond one minal erythemal dose) (MED), the skin becomes pink after a delay of two to four hours Redness occurs, which, depending on the severity of the burn, will begin to fade from overnight to within three to four days. In severe case, the redness may result in separation of the stratum corneum by edema and 'blistering'. The wavelength of maximum redness within the UV-B range is near the peak of UV-B or 305 nm.

UV-A is not directly associated with erythema, and has a redness producing potential compared to UV-B of about 1/1000. However, it has been shown to damage the skin by penetration to connective tissue, and is also capable of producing tumours. In addition to damage by the deeper penetration of UV-A, photosensitizing or allergic response due to a causative chemical and UV appears to be primarily caused by UV-A. UV-A is able to produce melanin, but the tan is more unstable than the melanin created by UV-B exposure. UV-A is used in tanning salons because of its lack of erythema, and its relatively quick tanning. It is doubtful, however, whether tans produced by exposure to UV-A will provide resistance to significant amounts of UV-B. UV-A exposure in tanning salons is not without hazards, especially to the deeper underlying structure of the dermis.

Due to the damaging potential of UV-B. both near term (sunburn) and long term (skin damage), and the deeper penetration and potentially greater damage from UV-A. proper protection from UV-A and UV-B must be exercised. Exposures to both UV-A and UV-B have been implicated in increased number of skin cancers.

The amount of solar radiation varies depending on the season, the latitude, the time of day. and the altitude. The closer to the equator, the greater the total radiation from ultraviolet. The same is true for any location during the summer, when the sun is at its closest point. From 9 a.m. to 3 p.m. represents the period of greatest exposure, while increasingly higher altitudes add to exposure levels. In addition, when directly in the sun. there is from 10 to 100 times more UV-A exposure than UV-B exposure. Consequently, both bands contribute significantly to harmful effects. An additional concern is that the vast majority of UV emitted by the sun is absorbed by stratospheric ozone. There is recent evidence that this ozone layer is decreasing, which will allow more UV-B to penetrate. A decrease in the ozone layer ol 10% is estimated to increase melanoma by 10-20%. basal cell carcinoma by 25-35%, squamous cell carcinoma by 50-6094), and cataracts by 6-10%.

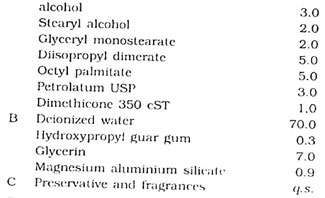

Sensitivity to UV irradiation depends on the amount of melanin, which absorbs UV, in the skin. Fitzpatrick and Pathak have developed a classification for skin types, depending on their response to UV irradiation (Table 2). This response is generally due to the level of melanin pigment in the skin. It is also typical of various racial or ethnic groups. Those groups who have a long history of sun exposure, e.g. black Africans, tend to be classification V or VI, while those with little history of sun exposure, e.g. people of Irish or Cellic heritage, tend to be category I or II. The normal reaction following exposure to meaningful amounts of UV is for the skin not only to produce more melanin, but also to thicken. The most serious effects are photodamage and cancer. Prolonged exposure can lead to profound changes in the fibrous component of (he dermis. with a decrease in collagen, alteration in keratinocytes and melanocytes and increased deep wrinkling and development of age spots. Continuous exposure leads to development on exposed areas of a wrinkled leather like appearance or 'red neck'. Skin cancers have been shown to be the direct result of overexposure to the sun. and the propensity of the individual to erythema and damage.

Australia, which has a high concentration of northern Europeans with Type I or Type II skin, and a location close to the equator giving maximized ultraviolet radiation exposure, has the highest reported incidence of skin cancer for a developed population. The most prominent form of skin cancer is basal cell carcinoma.

This cancer is typically preceded by a pre-cancerous lesion, a solar keratosis. This solar keratosis is easily removed by a dermatologist. The most serious form of skin cancer is a malignant melanoma, which usually arises from a mole and, it not treated early, is often fatal. Given the potential sun-damage to the skin, the need for sunscreen products is obvious. Some data suggest that 50% of a person's life time solar exposure occurs by the age of 18, therefore early usage is critical.

Sunscreen Chemicals

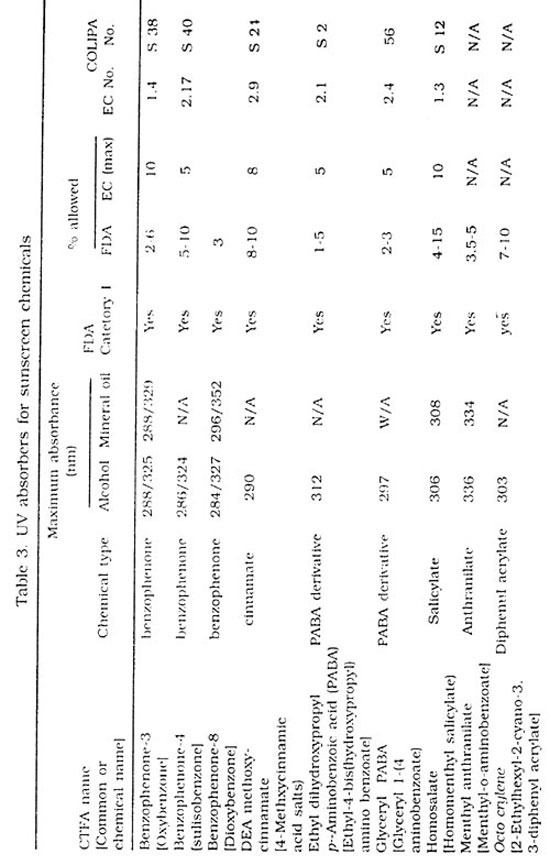

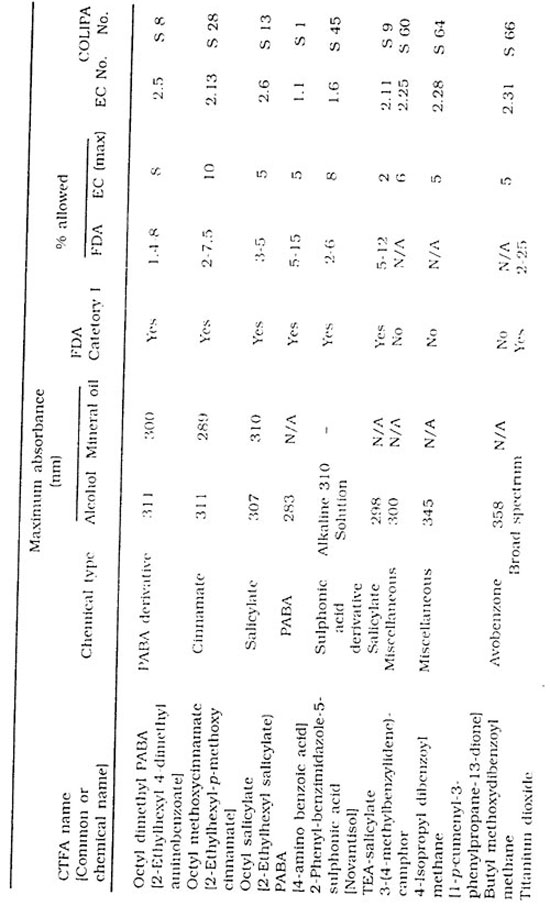

Sunscreen products are simply vehicles for materials (hat prevent meaningful amounts of UV radiation from reaching the skin. These materials are usually classified as chemical absorbers, or physical blockers and scatterers of UV radiation. In the US, they are recognized by the FDA 'over-the-counter drug regulations', which list various materials as Category I (safe and effective) sunscreens. In Europe, they form part of the EC and European Federation of the Perfume, Cosmetics and Toiletries Industry (COLIPA) positive list. An excellent review concerning the use of UV absorbers in sunscreen products has been written by Shaath. The materials can be grouped by name, chemical type, the wavelength at which they have maximum absorbance. al-lowed percentage usage in the US and EC, and by EC and COLIPA list numbers (Table 3). The vast majority of (he products listed in Table 3 are UV-B absorbers. The benzephones and butyl methoxy debenzoyl methane are UV-A absorbers. Titanium dioxide is a broad spectrum physical block.

Testing

Sunscreen products formulated with the sunscreen materials show in Table 3, at allowed or appropriate amounts, must be tested for performance. A number of in vitro performance tests have been developed and advocated, but the only currently accepted tests are in vivo tests. The standard tests vary from country to country, but are all similar. They are based on exposure to the sun or. more usually, to lamps that give carefully controlled amounts of radiation of very specific wave-lengths. A useful value has evolved to identify the efficacy of sunscreens. This is the sun protection factor or SPF, which is based; on production of redness on a test subject with a minima! erythemal dose (MED), representing the amount of exposure required to produce redness. The SPF is then the protection factor achieved with a specified layer of sun-screen applied to test subjects. For instance if individuals on average show a redness (MED) at 20 min. and. after the application of fixed amount of sunscreen product, show redness at 80 min. the product would have an SPF of 4. Much experimentation has been done to evolve alternative testing methods, and these are discussed in an excellent overall review of the subject of light protection by Groves.

The thickness of the applied film and lamps specified in sunscreen testing vary from country to country. The US and Europe differ significantly. Australia has separate standards and Japan is promulgating guidelines. Since these methods are under review and change, it is best to seek advice on acceptable testing from local trade associations, testing companies, sunscreen suppliers or regulatory bodies.

Another area of testing is that of waterproofness, which also varies from location to location. For instance, to support claims of waterproofness. the US PDA requires an in vivo test in which the subject is immersed in water for 80 min after application of product and then tested using the standard protocol. The claimed SPF must not be below the value achieved after immersion. Tests are now evolving and being advocated for testing protection versus UV-A exposure. At this point in time, no one test is yet accepted as standard.

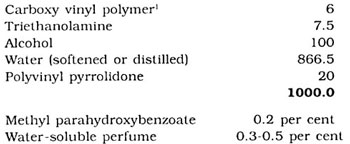

Sunscreen Formulations

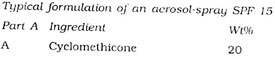

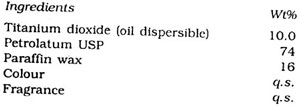

Products that contain active sunscreens must be carefully formulated in order to ensure that the sunscreen material is in its active form, is available when used, does not contain materials that adversely shift or diminish its absorbance, meets the SPF claimed, is waterproof if required, and is cosmetically elegant. There are many forms available, including the common lotions (generally O/W emulsions), oils (solutions of sunscreens in mineral oil, vegetable oil. volatile silicones or esters), gels of a water or water/alcohol character, sprays, and sticks for special application. Many modern sunscreens are formulated with combinations of raw materials that have absorbance in both the UV-A and UV- B range, as well as physical blocks to augment protection.

The esthetic properties of products are also important, as the product must go on easily, spread uniformly and. if necessary, depending upon usage and claims, establish a waterproof film. In general, there has been a steady increase in SPF value, the spectrum absorbed and blocked, and the requirement for formulas to be waterproof. The US FDA has established regulations and, for instance, does not allow products to be marketed as sunblocks unless they have a proven SPF of not less than 15. It is now common for products to have SPFs greater than 15, with some having SPFs approaching 50. Products with high SPFs require considerable formulation skills to maximize the effect of sunscreens used, and to make an elegant and often waterproof product with actives that may be used at levels greater than 20%. Increasing levels of sunscreen can also lead to problems of product irritation.

Due to the variation in sunscreen formulations, and the multitude of active ingredients and product forms, a careful study of available literature and the marketplace is essential before meaningful exploratory work with formulation can be initiated. Although there are relatively few manufacturers of sunscreen chemicals, their help can be invaluable.

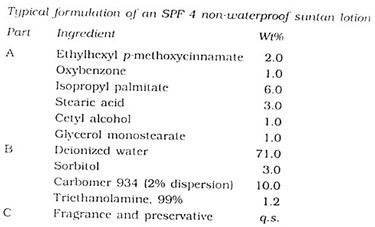

Suntan lotions These are generally O/W emulsions containing levels of UV absorber or physical blocks to give a desired SPF. Their formulation may differ from, that of conventional moisturizing lotions, in that significant amounts of oil phase are replaced by oil-based UV absorbers. In addition, if suntan lotions are required to be waterproof, they require addition of a water-repellent film former or some other means of ensuring adherence of the active to the skin. The following formula is that of a low SPF non-waterproof suntan lotion.

Procedure: Heat parts A and B separately to 70°C. Add part A to part B with good agitation. Mix to 35°C and add part C. Continue mixing until dispersion is complete.

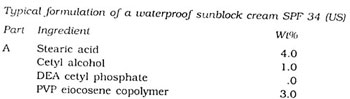

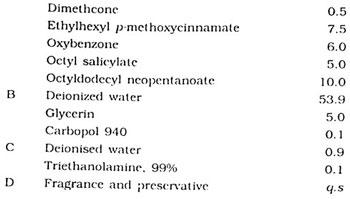

Waterproof sunblock creams These formulas incorporate significantly higher levels of sunscreens, and also contain waterproofing agents. The following formula is for an SPF 15 waterproof O/W lotion.

Procedure: Add part C to part B and mix until uniform. Add ingredients of part A and mix to dissolve evenly. Hold at 85°C. To form the emulsion, add part A to the mixed parts of B and C at 85°C. Mix and cool to 35°C. Add part D.

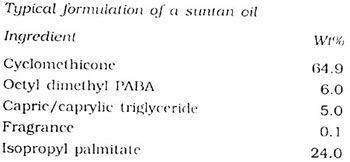

Simian oils Suntan oils are typically used by individuals who are seeking a tan. rather than by individuals who are seeking protection. They usually have a low SPF and are used not only to afford some protection for a longer exposure, but also to give a glistening appearance to pigmented skins. They are seldom waterproof and incorporate oil-soluble sunscreens into mineral oil. vegetable oils and derivatives, fatty esters, and combinations of the above, at times with above, a times with volatile silicone added to decrease oiliness.

Procedure: Blend in order at room temperature. Ensure thorough dispersion of rarbomer before adding triethanolamine.

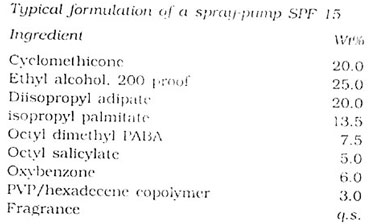

Sprays Most sprays are solutions of sunscreens in alcohol with or without, volatile silicone, or alcohol-soluble emollients. They can either be pump sprays or aerosol sprays, usually propelled by hydrocarbon propellanls. Such products are. by nature, light and easily spread on the skin. Since they are in volatile, bases, they tend to leave mainly sunscreen actives on the skin. Great care must be taken to ensure spreadability, and enough dispersion to ensure performance as well as maintenance of good estheties.

Procedure: Blend in order at room temperature. Ensure solution before addition of the next ingredient. Filter well before packaging.

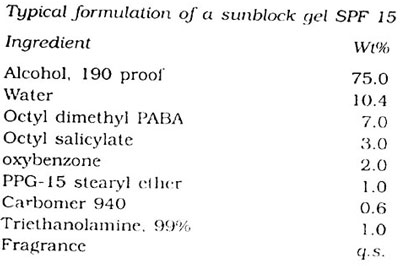

Sun gels These products are often alcoholic/water solutions of alcohol-soluble sunscreens, thickened with gums or polymers. They are cool to apply and represent a small but loyal sub-segment of the category.

Procedure: Blend in order at room temperature. Ensure solution before addition of the next ingredient. Filter well before packaging Part A is 100% formula for the concentrate. Fill into an aerosol container and charge with a suitable propellant.

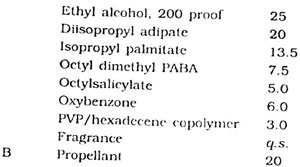

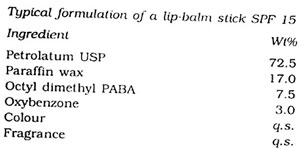

Sticks Sticks are usually for special application. They are of two general types: (i) for lips; and (ii) for areas that burn easily, such as the nose, ears and cheekbones. The formulas for lips are similar in nature to lip balm or lipstick formulas, and must be made of cosmetic raw materials that are edible. The products for areas that burn easily are often formulated with pigments that can act as total blocks. Zinc oxide, titanium dioxide, and talc are frequently used in a waxy matrix, not altogether different from the lipbalm products.

Procedure: Melt petrolatum and paraffin wax. Add other materials. Pour into molds or swivel sticks.

Procedure: Melt petrolatum and paraffin wax. Add other materials. Pour into molds or swivel sticks.

Everyday cosmetics with UV screens Many everyday cosmetic products, including colour cosmetics, are now being marketed with sunscreen actives in their formulation. Recently, protective UV variants of the most common hand and body moisturizer, as well as the most common facial moisturizer, were launched. These are products that contain sunscreens with an SPF of 4 and 15, respectively. It appears that many skin-care products for everyday usage will contain UV screens. It is critical for these products that the formulator takes extra care to ensure that esthetics do not suffer, that the active is stable, and that the products do not cause irritations with the mass of consumers who may be exposed to them on an everyday basis.

Acne

Acne vulgarises a disease that can range from occasional blemishes to a devastating, continuing episode leading to permanent scarring and much anguish. This section will discuss the various forms of acne and their treatment, except the treatment of cystic acne, which should only be treated professionally.

There are many misconceptions about aerie. It is not caused by diel. lack of cleansing, sleep or social habits, but by hormonal control. Both males and females secrete the male sex hormone testosterone. These secretions stimulate the sebaceous glands to secrete sebum. Acne is a disease that often develops due to genetic predisposition during puberty, and typically decreases during adulthood. The years of greatest severity are from 16 to 18 for women and from 8 to 19 for men. In white women, the incidence of clinical acne during the years of greatest severity is 40%, in men, the incidence is 35%. By the age of 40. 1% of men and 5% of women have lesions. The incidence among orientals and blacks is lower. The locations of acne lesions is generally on the face, neck, back and chest.

As discussed previously, the pilosebaceous system contains sebaceous glands and their associated hair follicles, both of which secrete sebum. Acne generally occurs in sebaceous glands that are either associated with fine or vellous hairs, or not associated with any hair. Humans are the only mammals that routinely develop acne; this is because they have lost their need for a hairy coating over the body, but still have many sebaceous glands without terminal hairs. In the presence of a coat, these glands would serve to wick sebum out on to the hair for the purpose of lubricating and waterproofing term

inal hairs, or for the purpose of providing an identifying odor.

Sebaceous Gland

As indicated previously, the sebaceous gland, with or without a hair, has its origin within the dermis. The follicle is, however, lined with statum corneum, creating the follicle wall. This stratum corneum sheds flattened dead cells into the follicle channel. This, combined with sebum, produces a mixture which, if it does not flow freely to the skin's surface, has the opportunity to plug, get infected and. through the enzymatic action of bacteria, break down certain components of sebum There are between 400 and 800 sebaceous glands per square centimeter, and it takes only one to become inflamed to cause an acne lesion. All of these are factors in the disease called acne, but none alone; is the direct, single cause. All individuals have sebaceous glands, containing sebum and bacteria. Some individuals have severe acne while others have little or no acne, sometimes only during adolescence. Individuals who develop severe acne are differentiated by the speed at which the epidermis lining the sebaceous gland produces and sheds cells. This is called retention hyperkeratosis. The increase of cells into an area rich with bacteria and lipid materials, including fatty acids, can cause an acne lesion. The acne lesion can be classified, and the acne graded by severity.

Acne Nomenclature