Chemical Composition, Anti-nutritional Factors and Shelf-Life of Oyster Mushroom (Pleurotus Ostreatus)

Some saprophytic fungi produce spore-forming umbrella-shaped edible fructifications called mushrooms. Various types of mushrooms are eaten in many parts of the world while some others, more commonly referred to as toadstools are poisonous (or even deadly poisonous), indigestible and unpleasant in taste. The problems of indigestibility and unpleasant taste have been linked to high levels of anti-nutritional factors in those fungi. Edible mushrooms are highly palatable and nutritious, containing 21-49% protein (dry basis) and are richer in vitamins B1, B2, B12 and C and minerals than most cereals and vegetables. In terms of protein content, they therefore compare favourably with legumes, many of which contain 20-40% protein. Mushrooms also contain an array of anti-nutritional factors. These toxic components generally include tannins, oxalates, phytic acid, hydrocyanic acid and alkaloids.

The oyster mushroom (Pleurotus ostreatus), locally called linaba (Ibibio in Nigeria) is a popular mushroom that is widely consumed in the rainforest zone of West Africa. In Nigeria, oyster mushroom, together with field mushroom, Agaricus compestris called mkpifia (Ibibio in Nigeria) were a primary source of protein for the mal-nourished and hungry populations in some parts of the Biafran Enclave during the 30 - month (1967-1970) Nigerian Civil War. The mushroom is currently obtained principally from the wild, where women and children collect them since it is not cultivated. Supply is highly seasonal and a glut usually occurs in the peak period (April - June), resulting in enormous losses due to improper post-harvest handling. In Nigeria, large quantities of this mushroom are harvested and presented in open trays (unpackaged) for sale to motorists by rural dwellers along many public highways.

Scientific information on Nigerian mushrooms is scarce. Most of the reports of Nigerian wild mushrooms in the literature are descriptive but a few reports on their nutritive values and toxicity have emerged. None of the latter, however, cover the oyster mushroom, P. ostreatus. This study was therefore designed to evaluate the chemical composition, toxicity, and storage life of this popular tropical mushroom.

MATERIAL AND METHODS

Sample collection, handling and analysis : Oyster mushroom samples were harvested from dead mango tree stumps in a garden at the day-old (button) and full-grown stages. In the laboratory, the mushrooms were cleaned, and each of the batches was divided into two sub-batches. One of each sub-batch was dried at 60°C to a constant weight. The dried (whole) samples were blended using a Kenwood blender and stored at ambient temperature in clean plastic containers until analysed. They were evaluated (within 3 days) for moisture content, crude protein, ether extract, crude fibre and ash according to AOAC (1980). Nitrogen-free extract (NFE) was determined from the formula :

% NFE = 100 - (% crude protein + % crude fibre + % ether extract + % ash + % moisture content)

The Atwater factors were used in calculating energy content. Anti-nutritional factors (phytic acid, tannins, oxalates and hydrocyanic acid) were determined using standard methods. The phyto-chemical substances were determined in both raw and boiled (100°C for 10 min) samples.

Storage: The remaining sub-batch of the full-grown stage mushrooms was further sub-divided into four subgroups. Each sub-group was weighed using a Mettler balance. The sub-groups (270 g each) were then randomly allotted to storage according to the following experimental plan :

(i) Storage without packaging at room temperature. (ii) Storage in perforated (12 perforations of 4 mm in diameter each) low-density polyethylene (20-mm thick) bags at room temperature. (iii) Cool storage without packaging. (iv) Cool storage in perforated low density polyethylene bags in the evapourator coolant structure (ECS).

Cool storage was carried out using a locally constructed low-external input, simple and cheap cooling system, the ECS developed by the Nigerian Institute of Stored Products Research, Ibadan, Nigeria. The cooling structure consists of two burnt clay pots, placed one inside the other. The space between the pots was filled with river bed sand and always kept wet which provides the cooling medium while the space inside the inner (smaller) pot provides the storage chamber. The top is covered with a slab made of the same material (clay) as the pots. Cooling takes place because of heat transfer from the produce (mushroom), in the storage chamber to the wet river bed sand (the cooling medium), from where the heat is further transferred to the outer surface, and eventually dissipated with the evapourating water. The system does not require electric power.

During storage, room temperature was 28±2°C while the evaporator coolant storage chamber temperature was 15±3°C. Weight changes were monitored daily. Samples were taken at the same interval for sensory (quality) evaluation and overall acceptance by a 10-member taste panel, using the 9-point Hedonic scale, ranging from 1 = dislike extremely to 9 = like extremely. Samples were prepared for evaluation by heating the mushrooms in boiling water for 15 min.

Statistical analysis : Data generated were subjected to analysis of variance. Means were separated using the LSD.

RESULTS AND DISCUSSION

Data given in Table 1 show the proximate composition of P. ostreatusn at the button and full grown stages. Table 1 also indicates the content of some major minerals in the mushroom. The full grown mushroom contained a significantly higher (P [ 0.05) level of protein than in the button stage. This observation agrees with Motskus. This author had previously reported that the chemical composition of mushrooms is markedly affected by the stage of growth, and that the mature mushroom is normally richer in protein. The results indicate that from the protein supply viewpoint, and to a large extent, the mineral supplysituation also (Table 1), it is more beneficial to harvest P. ostreatus at the mature flat stage than at the button stage. The results of the present study, however, largely contradict those of Chang who found the young fruit body of Volvariella volvacea to be the most nutritive stage of this mushroom. Kurkela had reported that mushrooms vary in their chemical compositions, and this may account for the observed differences between the present study and the earlier report of Chang. Maw has reported that the part of the

Table 1

Proximate and Mineral Composition of Oyster Mushroom at Two Growth Stages (% Mean Values ± S.E.)

| Component |

Button |

Full grown |

| Crude protein |

28.00±2.0a |

40.25±3.7b |

| Ether extract |

1.90±1.0 |

1.50±2.0 |

| Crude fibre |

7.00±4.0 |

7.40+1.4 |

| Ash |

6.20±4.0 |

6.80±4.0 |

| Moisture |

90.80±6.0 |

90.00±2.2 |

| Nitrogen-free extract |

36.33±1.7a |

46.55±2.0b |

| Energy (kcal/100g) |

412.44 |

686.52 |

| Calcium |

0.015 |

0.018 |

| Magnesium |

0.033a |

0.996b |

| Copper |

0.055a |

0.113b |

| Iron |

0.155a |

0.121b |

| Zinc |

0.278a |

0.221b |

| Phosphorus |

0.251a |

0.222b |

Values are the means of triplicate determinations. Means within the same row carrying different superscripts are significantly different (P [ 0.05)

Table 2

Levels of Anti-Nutritional Factors in Raw and Boiled Pleurotus Ostreatus (MG/100G)

| Factor |

Raw |

Boiled |

| Hydrocyanic acid |

1.16a |

0.16b |

| Total oxalate |

5.04a |

2.40b |

| Phytic acid |

42.24a |

14.08b |

| Tannins |

10.20a |

4.80b |

Values are the means of three determinations. Row means are significant (P [ 0.05).

Mushroom sampled also affects their chemical composition.

Results in Table 2 show the levels of some important phyto-chemicals (anti-nutritional factors) in P. ostreatus. The effects of heat treatment on these substances are also indicated. Heat treatment (boiling) generally brought about significant reductions (P [ 0.05) in the levels of anti-nutritional substances.

Changes in sensory evaluation of P. ostreatus during storage are shown in Table 3. The results indicate significant effects (P [ 0.05) of mode and duration of storage on the flavour, tenderness, colour and overall acceptance of the mushrooms. Overall acceptance showed strong positive correlations with the sensory parameters evaluated with R values of 0.988, 0.976 and 0.949 for colour, tenderness, and flavour, respectively. Ekanem had reported similar observations in stored (dried) clam meat. Low temperature had a marked effect on the shelf-life of the mushrooms. Samples stored in the ECS (15±3°C) lost acceptability (mean) acceptance score [ 5.0) on day 6 of storage, whereas mushrooms stored at room temperature (28±2°C) lost acceptability on day 2 and day 3, respectively for samples stored without packaging and those packed in polyethylene films.

Table 3

Changes in Mean Panel Scores (9-Point Hedonic Scale) for Flavour, Tenderness, Colour and Over all Acceptance of P. Ostreatus During Storage

| Storage method |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

| NRM |

8.7a |

6.1b |

5.5c |

4.9d |

- |

- |

- |

| NECS |

8.7a |

7.6c |

7.5e |

6.1b |

5.7bc |

5.1c |

4.3d |

| PRM |

8.7a |

6.6f |

4.5h |

- |

- |

- |

- |

| PECS |

8.7a |

7.5g |

7.5g |

6.8bg |

5.7c |

4.6d |

| |

|

|

|

Tenderness |

|

|

|

| NRM |

8.2a |

5.9b |

4.9c |

- |

- |

- |

- |

| NECS |

8.2a |

7.3cd |

6.9dj |

6.3j |

- |

4.1e |

- |

| PRM |

8.2a |

6.6e |

ND |

5.0h |

4.28 |

- |

- |

| PECS |

8.2a |

7.4cc |

7.0def |

6.5f |

- |

5.5g |

3.7h |

| |

|

|

|

Colour |

|

|

|

| NRM |

7.9a |

5.8b |

5.6b |

4.9c |

- |

- |

- |

| NECS |

7.9a |

7.9a |

6.1b |

5.7b |

- |

4.1d |

- |

| PRM |

7.9a |

6.5b |

5.9b |

4.9c |

- |

- |

- |

| PECS |

7.9a |

7.7a |

6.3b |

6.1b |

- |

5.2c |

4.0d |

| |

|

|

|

Overall acceptance |

|

|

|

| NRM |

7.8a |

5.5b |

4.3c |

- |

- |

- |

- |

| NECS |

7.8a |

7.8a |

6.9b |

6.3b |

- |

5.4c |

4.5d |

| PRM |

7.8a |

7.1a |

5.3d |

4.8d |

- |

- |

- |

| PECS |

7.8a |

7.8a |

6.9b |

6.2b |

- |

5.8bc |

4.7d |

NRM - Storage at room temperature without any cover

NECS - Storage in the Evapourator Coolant Structure without any cover

PRM - Polyethylene storage at room temperature.

PECS - Polyethylene storage in the Evapourator Coolant Structure

Column and row means carrying different superscripts are significantly different 0.05).

Mushrooms are reported to have a high protease activity which may cause deterioration of mushrooms, accompanied by undesirable changes in colour and flavour. Also, Meyer had reported that tannins (in which P. ostreatus is high) (Table 2) produce dark coloured complexes with metal ions, particularly iron, in stored plant foods. It has also been reported that tannins can cause astringency in foods. All of these factors (rapid breakdown of protein, production of dark compounds, off-flavour development and astringency) may jointly and severally account for the sharp fall in consumer acceptance of the mushrooms during storage.

There were significant effects (P [ 0.05) of mode and duration of storage on losses of weight in the mushrooms. Weight loss was maximum in samples stored at room temperature without packaging (Table 4). Mushroom samples given this treatment lost over 18% their weight within the first day of storage and over 70% by the third day when they also lost consumer acceptance. Comparatively low ([ 4.50%) but significant (P [ 0.05) weight losses were observed in samples stored in the ECS, whether or not they were packaged. This can be explained by the fact that the low temperature of the ECS slowed down physiological and respiratory processes. The relatively lower (P [ 0.05) weight loss in the packaged samples was due to reduced loss of water and availability of oxygen for metabolic losses during respiration due to the protective effect of the polyethylene bags. These are very well known effects in the storage life of plant materials.

CONCLUSION

This study has shown that oyster mushroom (P. ostreatus) is a fairly good source of protein and minerals. The mushroom contains some anti-nutritional factors, which are fortunately destroyed by heat. Proper cooking of the mushrooms should therefore be emphasised. The ECS, a traditional Nigerian cooling system, is demonstrated to be effective in extending the shelf-life of the mushroom. Recommendation and widespread adoption of this traditional device in the handling of mushrooms can markedly reduce the agony, frustration and losses suffered by rural dwellers, (mushroom harvesters, handlers and distributors) during gluts.

Table 4

Weight Losses (%) in P. Ostreatus During Storage

| Storage method |

1 |

2 |

3 |

4 |

5 |

6 |

| NRM |

18.50a |

40.70b |

70.30c |

- |

- |

- |

| NECS |

4.44b |

16.66a |

27.70c |

- |

35.10f |

44.40h |

| PRM |

5.55c |

25.90c |

- |

- |

- |

- |

| PECS |

3.70b |

9.25d |

20.30f |

- |

29.60e |

38.80a |

NRM - Storage at room temperature without any cover

NECS -Storage in the Evapourator Coolant Structure without any cover

PRM -Polytheylene storage at room temperature

PECS -Polytheylene storage in the Evapourator Coolant Structure

Column and row means carrying different superscripts are significantly different 0.5).

Mushroom Cultivation

The cultivation of edible Mushrooms is generally assumed to have begun in France around 1650. Gradually the cultivation spread first in Europe and in 1823, it was introduced in Netherlands.

Mushroom is a group of macroscopic fungi and lack of chlorophyll depends upon prepared nutrients. The terms Mushroom is often used loosely, however the common view is, the umbrella-shaped fungi belonging to Basidiomycotina, which are edible are called mushroom. In nature, mushroom grows wild in every country from snowy mountains to sandy desert, waste land, forest etc, and appear in all season but mainly in rainy season because organic matter decompose very easily.

Mushroom has to derive its nutrients from the organic matter on which it grows in common with many other. Mushroom is capable of using such indigestible substances as cellulose and lignin. Besides carbohydrates mushroom needs nitrogen but they can utilise nitrogen only in the form of protein and lignin. There are 1000 species of edible mushroom but use those that are cultivated by own hands or species you are familiar with and avoid all others. Earlier Mushroom was not particularly easy to cultivate, it was because their growing conditions were not properly known and it was practically impossible to influence those condition. It was only after the second World War that mushroom cultivation really began to develop in Netherlands as an Agro Industry. Around 1950, the first mushroom house equipped with ventilation and heating system was built.

ADVANTAGES OF MUSHROOM CULTIVATION

The artificial cultivation ensures that mushroom sold is truly edible. They are now regarded as useful food in modern diets, complementing the staple diet. Dieticians, to counter obesity and other syndromes associated with present-day eating habits, often prescribe them.

Plant residues such as straw, leaves, and also wastes from agriculture, forest and industry mostly remain unused. These are disposed off by burning or by some other wasteful and sometimes harmful methods.

However, by suitable treatment, these residues can be converted into substrates for the cultivation of mushrooms and the spent substrate can be utilized as manure.

Another advantage in mushroom growing is that they are grown in rooms, for which the wasteland may be utilized. Being grown in vertical stacks, for mushroom come into production very rapidly; makes mushroom growing a profitable venture.

There are various types of edible cultivated mushrooms prominent among them are:-

| Species |

General Name |

| Agaricus bisporus |

Button Mushroom |

| Entinus edobes |

Shiitake |

| Volvariella volvacea |

Paddy Straw mushroom |

| Pleurotus Sajor-Caju |

Oyster Mushroom |

| Auricular Species |

Wood Ear Mushroom |

| Flamblina Velu |

Winter Mushroom |

| Tremelia Fuctormis |

Silver Ear Mushroom |

| Pholiota Namelx |

Hameko/Vascid Mushroom |

The most commonly favoured variations in India are button, oyster and paddy straw mushroom.

Mushrooms contain higher amount of nucleic acid as compared to conventional foods. The comparison is presented as follows:-

| Food Item |

% Nucleic Acids (On dry weight basis) |

| Mushrooms |

2.1% |

| Cereals |

1.1% |

| Meat and Fish |

2.2% to 5.7% |

Mushroom protein is comparable to the high quality animal protein. It is superior to vegetables and cereals proteins. Hence it can substitute the non-veg diet and can provide a valuable source of high quality proteins to vegetarians. Mushrooms are regarded as one of the world's greatest untapped resources of nutritious and palatable food for future.

COMPARISON OF NUTRITIVE VALUE OF MUSHROOMS WITH OTHER FOODS

| Food acid (FAO) |

Essential amino acid Index (FAO) |

Amino Score |

| Mushroom |

98.6 |

90.0 |

| Beef |

100 |

98.0 |

| Chicken |

100 |

98.0 |

| Milk |

99.0 |

91.0 |

| Cabbage |

72.0 |

63.0 |

| Turnip |

69.0 |

68.0 |

| Tomatoes |

44.0 |

- |

Research data shows that mushrooms are highly nutritive food. Among all varieties of mushrooms, oyster mushrooms are virtually calorie free with high protein content. An analysis of some common edible mushrooms showed that on fresh weight basis the moisture content was 89-91 %; ash 0.97-1.26%; protein 2.78-3.94%; fat 0.25-0.65%; crude fibre 0.09-1.67%; carbohydrates 5.3-6.28% and energy value 24.4-34.41 K cal.

Agaricus bisporus contain 0.95% of manifold; 0.28% of glucose; 0.04% of pentoses; 0.59% of glycogen; and 0.90% of crude cellulose. Carbohydrates of mushrooms do not contain starch and cane sugar (sucrose). Glucose is present in very small quantity and like any other vegetable, mushrooms contain fat in small amounts. Therefore, mushrooms can be recommended as a 'Slimming diet'.

Many vegetables and cereals are deficient in some of the essential amino acids. Mushroom protein contain adequate quantities of most of the essential amino acids compared to those of egg protein, which is supposed to be a standard complete protein. A few essential amino acids, which are lacking in cereals are present in high concentrations in mushrooms. Therefore, mushrooms when supplemented with cereals in the diet will help in overcoming amino acid deficiency, particularly lysine. The mushroom protein is easily digestible and its overall quality is intermediate between vegetable and meat protein.

Most mushrooms are very poor in vitamin A and have high riboflavin and nicotinic acid, particularly thiamine, biotin and pentothenic acid. Folic acid, a B-vitamin known as a blood-building vitamin, is also available in mushroom. Thus, mushroom can go a long way to ward-off malnutrition. Mushrooms also have high mineral content, particularly phosphorus and potassium. Iron and calcium are in low concentrations, slightly less than a third of the total iron in mushroom is in the available form and can be readily utilized by the human body.

Mushrooms are a good source of several vitamins such as:-

- Thiamine,

- Riboflavin,

- Niancin,

- Ascorbic acid

Protein is the most critical component of food. Protein deficiency in the world is the most serious human nutritional problem. The quality of dietary protein is determined largely by essential amino acid present in these proteins.

Cereal and vegetarian diets which provide the bulk of proteins to the maximum population of the India are deficient in some of the amino acid particularly Lysine and Triptohen. Dietary proteins are split during digestion into their constituent units amino acids.

There are at least 20 amino acids, commonly found in food. Eight of them are classified as essential and they must be present in the diet. These eight essential amino acids can be listed as follows:-

1. Isoleucene

2. Leucine

3. Lycine

4. Methionine

5. Phenylalanine

6. Thronine

7. Tryptophen

8. Valine

In addition to them, Cystine and Tyrosine are usually included in essential amino acids as they have a sparing action on Methonine and Phenylalanine respectively.

SALIENT FEATURES OF MUSHROOM CULTIVATION

1. 100% risk free project: Heavy plant and machinery is not required, hence the capital investment is low. Similarly, running cost is also very low due to absence of any recurring maintenance expenses.

2. Low working capital: The raw material used for cultivation of mushroom is mainly agro waste like paddy and/or wheat straw. Hence, the requirement of working capital is very low.

3. Latest technical know how: The latest cultivation techniques, know how etc. for quality mushroom would be supplied by various agricultural universities, IARI constituents, CSIR labs etc.

4. Very high returns: Agro waste like paddy straw, wheat straw, sugar cane waste etc. are converted into compost, which is used as bed for cultivation of mushroom. Thus agro-waste is converted into on income generation activity.

5. Low execution period: The project can be executed from concept to commissioning within four months.

6. Easy financing: Mushroom cultivation is considered to be an agro project, which is thrust area for development. Hence finance is available from Banks on top priority.

7. Long term business: International as well as domestic market is growing at a faster speed. Presently there is huge gap in demand and supply. By a conservative estimate the domestic demand for mushrooms would be about 3,000,000 tonnes per annum by the year 1998. Presently only 5000 tonne is being supplied in domestic market.

8. Pollution free environment friendly project: The mushroom cultivation project is free from any type of pollution, rather it is helping the nature by maintaining the bio-cycle.

IMPORTANCE OF MUSHROOM CULTIVATION FOR INDIA

(a) Mushroom cultivation is a highly labour intensive activity. India has abundance of rural labour, which is suited for such a project.

(b) Mushroom harvesting cannot be effectively automated: Manual operations are best suited for Indian industry as it ensures creation of more employment.

(c) Mushroom helps in maintaining the cycle of nature by decomposing agro residues. This agro waste is available in abundance in our country.

(d) Mushroom is a good source of high quality proteins and rich in vitamins and minerals. It is an ideal food for vegetarian population in India.

(e) Mushroom cultivation provides excellent opportunity to educated rural youth to become entrepreneurs and provide jobs to others.

(f) Mushroom cultivation provides opportunity to use wastelands except water logged land, which is abundantly available in India.

(g) Mushroom cultivation provides excellent opportunity in rural areas near by the metropolitan cities to become economically sound by selling mushrooms in urban areas because of great demands of mushrooms in metropolitan cities.

(h) The rural women whether they are educated or uneducated can easily handle such type of projects very easily along with their house jobs and become economically sound.

TYPES SUITABLE FOR CULTIVATION

At present three mushrooms are being cultivated in India. These are: white button mushroom (Agaricus bisporus), paddy-straw mushroom (Volvariella volvacea) and oyster mushroom (Pleurotus sajor- caju). Of these, A. bisporus is the most popular and economically sound to grow and is extensively cultivated throughout the world.

However, due to its low temperature requirement, its cultivation is restricted to the cool climatic areas and during the winter in the plains of Northern India. In summer, the tropical paddy-straw mushroom is suitable for growing in most suitable parts of India.

Oyster mushroom can grow at moderate temperature ranging from 22° to 28°C. Therefore, it is suitable for most of the places in India.

In North India, the climatic conditions prevailing during different seasons can be exploited for growing mushrooms throughout the year. To this a year-wise production schedule is suggested:

| Mid-November |

Agaricus Bisporus |

| February to Mid-April |

Pleurotus Sajor-caju |

| Mid-June to mid-September |

Volvariella volvacea |

| September to November |

Pleurotus sajor-caju |

Cultivation of White Button Mushroom (Agaricus Bisporus)

Agaricus bisporus can be grown anywhere if the essential conditions are obtained or controlled. These conditions are: temperature, moisture, ventilation, and good spawn.

TEMPERATURE

The temperature requirement for the spread of the mycelium or vegetative growth is 22-25°C. For the reproductive stage or fructification; the temperature requirement is 14-18°C. Within the limits prescribed, the temperature should be uniform throughout the growth of the crop. If it is too cold the development of the spawn will be retarded or arrested. A high temperature will favour the development of moulds and bacteria, which will soon destroy the spawn or crop.

MOISTURE

Moisture is an important factor in the cultivation of the mushroom and needs careful application. The mushroom requires an atmosphere nearly saturated with moisture, yet the direct application of water on the beds is more or less injurious to the growing crop. They should be protected from a dry atmosphere or spring drought. When watering becomes necessary it should be applied in a fine spray around the beds with a view to restore the moisture in the atmosphere.

VENTILATION

Good aeration is essential for a healthy crop, as ventilation is one of the important factors governing mushroom production. Ventilation is responsible for the maintenance of congenial environmental conditions and also for the removal of toxic gas by the introduction of adequate fresh air. The information available indicates that the CO2 level of 0.10 to 0.15 per cent volume is necessary during crop production and this can be achieved by giving 4 to 6 air changes/hour or introducing 10 cubic ft fresh air/sq ft bed area/hour. Van Soest (1977) gave a rule of thumb formula, i.e., at a bed temperature of 16°C, one cubic metre of fresh air per hour per square metre of bed area for every kilogram of mushroom produced. Every degree centigrade increase in bed temperature above 16°C increases the production of CO2 by about 25 per cent. This implies that the number of air changes must be increased by 20 per cent. However, drought must be avoided as it will cause rapid desiccation and the beds will also be affected.

GOOD SPAWN

Spawn is merely mycelium from a selected mushroom grown on some convenient medium and it is the strain of mushroom selected which decides the type of mushroom the spawn will produce. The essential qualities of good spawn are:

(a) It should be of a strain originating from a single specimen of a perfect crop.

(b) It should have the following aspects: The substratum must be covered with the white mycelium, it must be uniform and at the moment of removal from the container, should be absolutely free not only from mould but also from all other microorganisms. Although some of these characters may be visible at a glance, a good spawn cannot in principle be distinguished from bad spawn merely by looking at it. Sometimes odour may help to remove the suspicion. Fresh spawn has a strong mushroom odour, dried spawn is odourless. But only a thorough examination and test can establish whether the spawn is good or bad.

SUITABLE GROWING SPACE

Mushrooms may be grown successfully in a variety of places. Commercial and amateur mushroom growing is done indoors.

The following space requirements are necessary for successful production:

1. The location should be easily accessible so that the manure and casing soil can be brought in and removed with ease.

2. The room should be well ventilated.

3. No direct sunlight should fall on the bed. Diffuse light however, will not harm mushroom growing.

4. The room temperature should not exceed 20°C during the growing period.

5. Heating facilities should be provided so that the room may be heated when the temperature drops low.

6. The location should have sufficient protection and insulation so that it is not subjected to sudden fluctuations in temperature, since mushrooms cannot withstand sudden changes in temperature.

7. Location for growing mushrooms should not be too moist. The idea has gained ground that mushroom should be grown in humid, badly ventilated rooms. This is an entirely wrong notion. Mushroom does not develop well in too high humidity and will not develop at all with insufficient ventilation.

8. The best way would be if each unit is filled at one time and is arranged so that it can be closed up tightly and completely isolated from its surroundings, in order to facilitate the fumigation and disinfection of the beds.

9. Near the location of mushroom growing, there should be good fresh water supply, availability of the fertilisers for making compost and a good market for the disposal of the mushroom.

Mushrooms have been grown successfully in cellars, garages and in any abandoned room. For the cultivation of white button mushroom (Agaricus bisporus) the following steps should be adopted.

- Compost and methods of composting

- Spawn and methods of spawning

- Casing

- Harvesting

COMPOST AND METHODS OF COMPOSTING

Compost is the substrate on which mushroom grows. The biochemical activities of a number of microorganisms make the substrate selective for the growth of mushroom, A. bisporus. The process of compost making is known as Composting.

Composting is defined as indefinite microbial degradation of organic wastes. These wastes include vegetable and animal matter, forest litter, remains of stubbles and roots in the soil, green manure, straw, household garbage, sewage sludge, animal manure, etc. The process of composting involves microbial proteins and conditioning of the fibrous material to absorb and retain moisture. In addition, the microorganisms change the physical properties of compost and make the growth of the competitive microorganisms more difficult.

The quality of the mushroom compost depends on:

- nature and quality of basic materials,

- organic and inorganic supplements and

- management of the compost during composting.

NATURE AND QUALITY OF THE BASIC MATERIAL

Compost making with horse manure and its straw bedding is the most conventional method adopted by commercial growers. Horse manure, bedding (straw) and urine form the most balanced medium for rapid decomposition and do not need any supplementation for making good compost. Some horse manure compost also needs supplementation to make good compost when it is collected from a cleaned stable; where it does not receive a major part of the urine, an addition of small amount of inorganic nitrogen will give better result. In case of the manure with less bedding, addition of straw provides good physical condition to the compost and makes a better substrate for the growth of Agaricus bisporus.Keeping these elementary principles in mind, one can proceed to make good compost for A bisporus.

According to Atkins, horse manure is the best substrate although the manure of mules is as good as that of horses. He could not find that cow manure had any advantage over horse manure. One-third manure of well-fed cattle with two-third horse manure worked very well. Peat moss mixed with loam used as bedding of horses was an acceptable supplement to the horse manure.

In cattle manure the problem is of high variability of the raw material used as cattle feed. The important factors are the proportion of straw in the manure, its moisture content, age, method of collection and storage. Old, heavy weight manures are valueless for composting as they are considerably decomposed and have lost the ability to heat up. Relatively fresh cattle manure in which the straw still retained its original colour to a large extent proved to be very satisfactory for composting. The very strawy manure does not compost properly and remains tough and spongy, whereas the strawless manure makes a very compact heap, having large anaerobic zones, intermediate manure can be used. In cattle manure nothing except gypsum should be added.

Since horse manure is becoming scarce, attempts have been made to find suitable substitutes. In order to produce an economical and competitive artificial manure or "synthetic" compost, industrial wastes and agricultural byproducts can be used. There are few factors which should be kept in mind for selecting a substitute for horse manure:

(i) The composting period of the substitute should be the same or lower than the horse manure

(ii) It should be easily available to the growers and at competitive rates as the horse manure

(iii) Its production capacity should be equal or better than horse manure.

Several workers have studied the possibility of wheat straw, barley straw, rice straw, rye or oat straw, maize stem, corn cobs, etc. mixed with organic and inorganic supplements as a replacement for making the synthetic compost.

In preparing the compost from straw as the only plant residue many difficulties are faced. Mainly it is the slowness with which the straw gets wetted followed by delayed action of microorganisms. On wetting the straw, a sequence of microbial events is initiated. First a mixed flora (bacterial, actinomycetes and fungi) of mesophylic nature which grow and multiply below 40°C (104°F) increases in number. As the temperature of the pile increases, a thermophilic and thermotolerant flora which can grow and multiply at temperature above 40°C take over. This flora survives until peak heat is terminated by cooling, then there is again an increase in number of mesophilic organisms especially in long method of composting. Microorganisms make use of nitrogen and carbon for their metabolic activities. The energy required for this process is derived by aerobic and anaerobic decomposition. Wheat straw is mostly used for making the synthetic compost. In rice growing area rice straw is also used but the quantity of rice straw should be more as compared to wheat straw.

Barley straw can also be used for making the composts. This straw softens in shorter period during composting. The yield of mushroom is the same, both in the case of wheat and barley straw, but the compost produced from the barley straw is much less.

Stoller reported that fibrous material like spent licorice roots (from which the licorice has been extracted) and spent tannery nuts, bark and leaves (byproducts after tanning extraction for industrial use) are even more satisfactory than straw. These materials already contain sufficient moisture, they are suitably decomposed and require only a short or no microbial decomposition.

After much experimentation on composting it has been found that a certain balance between cereal straw and a plant material in a green state can form an ideal mixture for the preparation of a mushroom compost. The green material, whether freshly harvested or dried, will hold the water and absorb the added water readily and will begin to undergo immediate decomposition. Temperature also rises rapidly and within a few days, the compost is ready. The green material supplies the microorganism with some of the nitrogen and the minerals which are required for the decomposition of the straw although sometimes additional inorganic salts are required, depending upon the nature of the material used and their relative concentration. Compost with maize stem has been tried. In this case a year old well-preserved maize stem is cut into small pieces and mixed with wheat straw in the ratio of 2.5:1 on the basis of dry matter. The straw improves the structure of the material. About 1.2:1.5 parts of broiler manure is also added to enrich the nitrogen content of the compost. Compost with crushed corn cobs can also be prepared. Crushed corn cobs and wheat or rye straw in the ratio of 2 to 1.5 is the most ideal ratio. On the basis of dry matter, broiler manure can be used as a nitrogen supplement to corn cobs.

As an alternate to cereal straw, the primary ingredients for mushroom substrate can be vegetable material such as sugarcane bagasse, pulverised tree bark and wood waste.

Sawdust can also be used for making compost. Sawdust is advantageous over compost compost material, as it does not require grinding and is uniform in composition, it is easy to mix and handle. Hard wood such as oak, birch, beech and maple is suitable for the purpose. The unsuitability of soft wood is due to the presence of resins and lignin.

Sewage sludge is a very desirable supplement for sawdust. It is dried and mixed thoroughly with the saw dust before composting. If the sludge is not dry but watery or diluted, only a small quantity can be added without making the sawdust too wet. If the sawdust is partially dried and pasty it is very difficult to mix. Sludge is a good source of microorganism and the microbial growth substances, which may be very helpful in composting. Sawdust compost if correctly made is a useful substitute for horse manure compost. The temperature in the sawdust does not go very high during composting but if sludge is added to the sawdust, then the temperature goes a little higher than where sludge is not mixed. The required temperature during composting can be attained with nitrogen supplement.

ORGANIC AND INORGANIC SUPPLEMENTS

In the preparation of synthetic compost the presence of nitrogen, phosphate and potassium in different ratio is essential. Deficiency of any one of these will cause reduction in yield. The number of sources hardly matter as long as they provide the desired ratio. The C : N ratio plays the most important part and for good compost this ratio is about 17:1. The supplementation of organic matter for an optimum result varies as per the basic material.

Nitrogen supplementation is also a very important factor. Deficiency of nitrogen often limits the yield, but by increasing the nitrogen, the yield increases. Increase of nitrogen should be up to 3 per cent level of the finished compost at the time of spawning. During the early stages of composting, much of the nitrogen is ammonified and in later stages, the ammonia re-combines with microbial protein which is a good nutrient for mushroom. Ammonia as such is very toxic to the mushroom.

The amount of nitrogen supplement is calculated in such a way as to give 2 to 2.5 per cent total nitrogen content in the starting mixture. Organic nitrogenous sources are better than inorganic ones because they supply carbon, potassium, phosphorus and also have a better heating capacity. Organic nitrogenous material may be unsatisfactory sometimes due to the presence of toxic substances. The selection of the nitrogen source depends upon the cost of the material comparable to the yield of mushroom obtained. The supplementation of organic matter for good results varies as per the basic matter. In the case of inorganic nitrogenous substances like ammonium salt, and cyanamide, special precautions should be taken while nitrates may be used freely.

The poultry manure can be used to replace part of the organic nitrogen supplement and to give good yield. It also adds a significant amount of fine dry matter to the compost which helps to counteract the strawiness of the horse manure and improve the texture of the compost. For supplementation of the nitrogen source any other nitrogen-rich organic material can be used. The amount of organic matter and nitrogen have to be the same as in chicken manure. If less chicken manure is used, it is possible to apply urea or ammonium nitrate as nitrogen source but if the amount of chicken manure becomes too small, the yield is negatively affected because of the shortage of the available carbon source. The structure of the compost is very important and there should be definite dry matter, water, air ratio during composting in order to have an optimum heating of the compost. If the straw is very fine for synthetic compost, less chicken manure can be used.

In the case of fresh horse manure, increasing the amount of ammonium sulphate and calcium carbonate generally increases the yield, but the reverse is the case with old horse manure. Increasing the amount of ammonium sulphate delays the decomposition in the pile, while a very high amount completely stops the fermentation. Increasing the amount of calcium carbonate slackens down the decomposition but does not reduce the yield. The addition of a limited amount of ammonium sulphate shows faster decomposition. It is necessary to study the combination of ammonium sulphate and calcium carbonate thoroughly. One should be careful to add the right type of supplement, as chicken manure does not increase the yield with the combination of ammonium sulphate and calcium carbonate along with cotton seed meal, it is more effective. Similarly, ammonium sulphate with or without limestone does not give an increases in the nitrogen content of the compost but it increases the ammonia content which reduces the yield. Ammonia content above 0.3 per cent reduces the yield. There is a highly significant correlation between nitrogen and yield for synthetic compost but not for natural compost; therefore, a nitrogen supplementation which increases nitrogen without any increase in ammonia contents is desirable.

Supplementation would be much cheaper if the ammonia from a cheap nitrogen source such as sulphate of ammonia could be converted into microbial protein by the microbes. This can be possible with the addition of available carbohydrate to the compost. Most often organic nitrogen is used as an activator, ammonium nitrate is the basic inorganic nitrogen supplement. Urea is often used as a source of free NH3 during composting.

The composting process must, therefore, be regulated to produce a high amount of protein and a minimum amount of ammonia. Cotton seed meal, wheat flour, dried skim milk, fish meal, gluten meal, linseed meal, soybean meal, malt sprouts, meat scraps, ground rye grain, cotton steep liquor, Brewer's grain, molasses, corn syrup, etc., were used by Schisler. Out of all these sources, cotton seed meal gives the best results. It means that the plant concentrates having a high protein content gives a greater increase in yield than the animal concentrates. Molasses encourage the growth of bacterial and other moulds and hence reduce the yield. The combination of cotton seed meal, molasses, flour, etc., with skim milk gives an increase in yield whereas no significant increase was observed when they were added separately or in combination with each other.

The increase in yield is not achieved by merely adding more nutrient but it is increased by adding that particular/nutrient in which the compost is deficient. An addition of nutrient in an already balanced compost would not help to increase the yield. After a certain limit of supplementation there is no further increases in yield, it is perhaps due to the poor growth of either the composting microorganism or the mushroom mycelium itself. When a higher amount of supplement is added, sometimes heating occurs which affects the yield.

MANAGEMENT OF THE COMPOST DURING COMPOSTING

There are two main methods of composting- long method and short method. The long method takes about three to four weeks whereas composting by short method takes 12 days.

Long Method

The compost should be prepared on a well-cleaned, pucca and preferably cemented floor. It may be done either in the open or under a shed whose sides are open. If composting is done outside, then the heap should be protected from rains by coveringthen the room should be well ventilated.

There are two types of compost: (i) natural compost and (ii) synthetic compost.

Natural Compost: Natural compost is prepared from horse dung obtained from stables in which abundant wheat or barley straw has been used for bedding. It is desirable to add one-third the weight of wheat straw to the horse dung. It should never contain an admixture of dung from other animals but 100 to 110 kg chicken manure and 3 kg urea per tonne may be added. The dung must be fresh and must not have been exposed to rain. The manure as obtained from the stable in a damp condition is made into a heap 1 metre high. After 3 or 4 days, when the heap begins to steam due to fermentation and gives off an odour of ammonia, it is opened up. This is repeated 4 to 5 times at an interval of 3 to 4 days. Twenty-five kg gypsum per tonne of horse dung is added in two instalments at the second and third turning. At the final turning, nematicide is mixed in the manure.

Synthetic Compost: The following ingredients are required.

| Wheat straw (chopped 8 to 20 cm long) |

250kg |

| Wheat bran |

25kg |

| Ammonium sulphate or calcium ammonium nitrate |

4kg |

| Urea |

3kg |

| Gypsum |

20kg |

This will make compost to fill up about 15 to 16 trays.

Wheat straw is spread over a pucca floor and wetted thoroughly by sprinkling water. Wheat bran and other ingredients except gypsum are mixed thoroughly in wet straw, which is finally stacked into a pile about 1 metre high and 1 metre wide. The heap is compressed by applying light pressure.

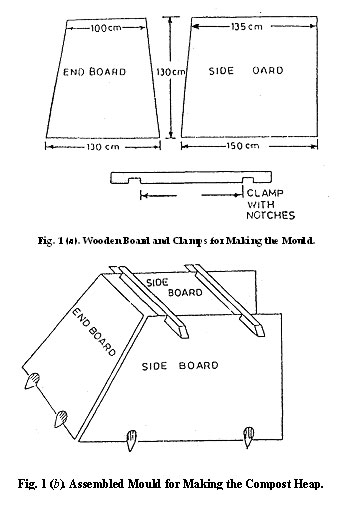

The heap with mixed ingredients can also be made with the help of the wooden mould. It has three wooden boards-one end board and two-side boards. The side boards can be attached with the end board by clamps as shown in. The whole board is kept on the ground. The mixed compost ingredients are put in the mould and compressed slightly. The side boards are detached from the end board and are moved lengthwise, again the mixed ingredients are put in the mould, this way a long pile of the compost can be made. The pile should not be pressed tightly otherwise anaerobic condition will set in. If a long heap is made then perforated pipes can be placed vertically in the heap for aeration. It is essential to open the entire pile and re-do it a number of times according to the following schedule.

| Stack the heap |

0 day |

| 1st turning |

5th day |

| 2nd turning |

10th Day |

| 3rd turning |

14th day, add 10kg gypsum |

| 4th turning |

18th day, add 10kg gypsum |

|

| 5th turning |

22nd day, spray with 40ml nemagon |

| Final turning |

26th day, spray 10ml melathion in 5 litre water |

At each turning water should be sprinkled to make up the loss of water due to evapouration. The compost, when ready for spawning, is dark brown in colour and without any smell of ammonia and has sufficient moisture when pressed between the palm.

Many formulae have been given by different workers.

Formulae given by Indian Institute of Horticultural Research, Banglore:

Formula 1

| Wheat straw (6 inch pieces) or |

300kg |

| Paddy straw |

400kg |

| Ammonium sulphate or calcium ammonium nitrate |

9kg |

| Superphosphate |

9kg |

| Urea |

4kg |

| Wheat bran |

30kg |

| Gypsum |

12Kg |

| Calcium carbonate |

10kg |

Straw must be kept wet for two days. When paddy straw is used, add 6 kg cotton seed meal on the 4th turning. All fertilisers are broadcasted on moist straw before making the heap.

Formula 2

| Paddy straw |

150kg |

| Maize stalk |

150kg |

| Ammonium sulphate |

9kg |

| Superphosphate |

9kg |

| Urea |

4kg |

| Rice bran |

50kg |

| Gypsum |

12kg |

| Calcium carbonate |

10kg |

| Cotton seed meal |

5kg |

These two formulae are used for long methods of composting and schedule of turning is days 0, 6, 10, 13, 16, 19, 22, 25, 26 (filling).

Formula 3

| Horse manure |

430kg |

| Wheat straw |

250kg |

| Chicken manure |

100kg |

| Brewer's grain |

30kg |

| Urea |

7kg |

| Gypsum |

20kg |

Formula 4

| Wheat straw |

300kg |

| Chicken manure |

120kg |

| Rice bran |

20.6kg |

| Brewer's grain |

22kg |

| Urea |

6kg |

| Cotton seed meal |

5kg |

| Gypsum |

10kg |

Formula 5

| Wheat straw |

1000kg |

| Chicken manure |

400kg |

| Brewer's grain |

72kg |

| Urea |

14.5kg |

| Gypsum |

30kg |

Formula 6

| Paddy straw |

3 ton |

| Chicken manure |

1½ ton |

| Wheat bran |

125kg |

| Gypsum |

90kg |

Formula given by Seth (1975)

| Long method of composting |

|

| Wheat straw |

1 ton |

| Calcium ammonium nitrate (CAN) |

30kg |

| Superphosphate |

25kg |

| Urea |

12kg |

| Sulphate of polash |

10kg |

| Wheat bran |

100kg |

| Molasses |

16.6 litre |

| Gypsum |

100 kg |

| Nemagon |

266 ml |

Turning schedule

| 0 day |

Stack |

| 1st turn |

5th day (50 per cent nitrogen fertiliser) |

| 2nd turn |

7th day (molasses) |

| 3rd turn |

10th day (gypsum + nemagon and fill in the container) |

It was allowed to remain in the container for 8 to 10 days. The temperatures in and outside compost as well as in the container ranged between 72 and 76°C.

Formulae given by Garcha (1981)

Formula 1

| Wheat straw (Turi) |

300kg |

| Calcium ammonium nitrate (CAN) |

9kg |

| Urea |

3kg |

| Superphosphate |

3kg |

| Muriate of potash |

3kg |

| Wheat bran |

15kg |

| Molasses |

5kg |

| Gypsum |

30kg |

| Lindane dust or BHC (5 per cent) |

250kg |

| or |

|

| Linotox |

60ml |

| Nemagon |

30ml |

Formula 2

| Wheat straw |

300kg |

| Poultry litter |

60kg |

| Calcium ammonium nitrate (CAN) |

6kg |

| Urea |

2kg |

| Superphosphate |

3kg |

| Muriate of potash |

3kg |

| Wheat bran |

15kg |

| Gypsum |

30kg |

| Lindane dust or BHC (5 per cent) |

250kg |

| or |

|

| Linotox |

60 ml |

| Nemagon |

30ml |

Paddy straw can also be used instead of wheat straw. However, the equivalent of 300 kg of wheat straw should be 400 kg paddy straw. The other ingredients remain the same.

Formula given by the Srinagar laboratory

| Wheat straw |

300kg |

| Molasses |

12kg |

| Urea |

4.5kg |

| Wheat bran |

50kg |

| Gypsum |

12kg |

| Muriate of potash |

2kg |

| Cotton seed meal |

5kg |

Short Method

| Described by Sinden, this composting has two phases. |

|

| Ingredients |

|

| Chopped wheat straw |

1000kg |

| Chicken manure |

400kg |

| Brewer's grain |

72kg |

| Urea |

14.5kg |

| Gypsum |

30kg |

Phase I. Outdoor composting. Prestacking-four days

Brewer's grain and chicken manure are added to wheat straw. Sufficient water is added but there should be no leaching. The stack should be 3.3 Ã- 2.5 Ã- 1.0 metre. Give turning and make the stack of slightly smaller size (3 m Ã- 2 m Ã- 1 m). Straw is trampled with feet and watered if necessary.

| 0 day |

Prepare heap in the usual way as in long composting. Add full quantity of urea and spray water if necessary. |

| Day 2 |

Give first turning. |

| Day 4 |

Give second turning and add full quantity of gypsum. |

| Day 6 |

Give third turning. |

| Day 8 |

Fill in trays for steam pasteurisation. |

The pH of compost should be 8.5. In case it has less nitrogen supplementation should be done but the nitrogen should not exceed 2 per cent of the dry weight.

Phase II. It has two main purposes.

- Conversion of ammonia into microbial protein.

- Pasteurisation-Killing of microorganisms which are competitors and to make the substrate suitable only for Agaricus bisporus.

Phase II can be completed either by steam heat or fumigation with methyl bromide.

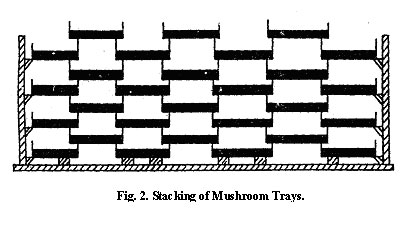

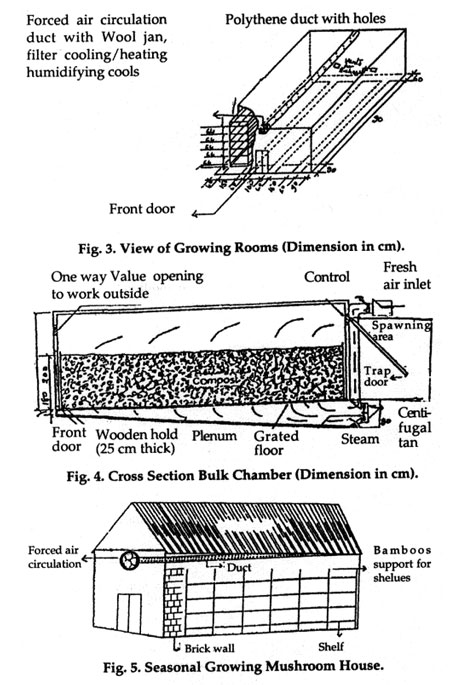

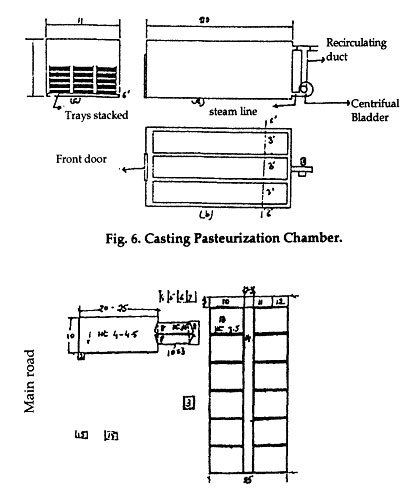

Steam pasteurisation: Initially live steam or dry heat is introduced to raise both air and compost temperature and then fresh air is introduced to establish anaerobic fermentation. For this phase the temperature should be between 52 and 60°C in the compost. There should be free circulation of moist air around the beds and oxygen supply should be between 15 and 20 per cent. For these conditions a well-insulated room is required. Trays evenly filled with compost are stacked in a pre-warmed room as quickly as possible to avoid heat losses. Sufficient space is kept between the trays to allow the free movement of the air. All ventilators and doors are closed. Live steam is introduced to raise the temperature of compost up to 52 to 54°C. This temperature is maintained for 2 to 4 days. After that, the temperature of the compost is further raised to 58 to 60°C for 4 hours. The steam supply is shut off and fresh air is introduced slowly and gradually by controlling the ventilation system to lower the temperature of the tray beds (2 to 3°C per 24 hours). The temperature of the bed is lowered to 52 to 54°C and the same temperature is maintained for 4 days. By this time ammonia completely disappears from the compost and the temperature is further lowered to 24°C. Now it is ready for spawning. Fresh air circulation is essential throughout phase II to equalise the temperature and to supply oxygen to every part of the compost. Lack of oxygen in phase II reduces the thermogenesis within the compost. If with sufficient oxygensupply there is a weak thermogenesis it shows that the phase I condition was extended too long or the condition of phase I was not proper.

In phase II, if the ammonia smell persists for more than 60 to 72 hours it denotes that the composting process was not correct or excess of nitrogen was added in the beginning. Sometimes the air temperature is raised to 55 to 60°C to kill the insects and spores of competitors. This process is done at the end of phase II when active thermogenesis is completed otherwise there will be overheating of the compost. Phase II ends abruptly with a rapid decline of temperature to 25°C. Spawning is done immediately.

A COMPOST FERMENTATION METHOD BY MEANS OF FORCED AIR CIRCULATION

This method was devised by Neng. This is actually a process of outdoor composting with indoor pasteurisation.

Fermentation Chamber for Compost

A hollow double-sheet plastic cloth sealed all the edges by heat. The plastic cloth has to exclude ultraviolet light. Redmud plastic is used in this experiment. Once the air is sent to the compost centre and flown out into chamber, space increasing its pressure within, and the hollow air pack is filled up with air, it becomes immediately a fermentation chamber of compost.

Formulation of Compost

By the conventional method in Taiwan, the compost has been made from rice straw and some chemicals with a ratio by weight as follows:

| Rice straw |

100 |

| Urea |

1 |

| Ammonium sulphate |

2 |

| Calcium superphosphate |

2 |

| Calcium carbonate |

2 |

| Lime |

2 |

| Water |

200 |

Process of Composting and Fermentation

Rice straw was cut to 10-12 cm before adding the lime solution for preparing the stack. Two days later all chemicals described above are added, and the proper amount of water is given, for the stacking. When the first turning is done on fourth day after stacking, the turned compost is put on the plastic film prepared on the ground. An air duct is laid across under the centre of compost and connected to a blower. Then everything is covered with the specific double-sheet plastic cloth. When the blower starts, the air is sent through the air duct to the compost centre and it flows out into the chamber space increasing gradually its air pressure within. Eventually, the plastic cloth becomes an arch-shaped fermentation chamber. The air inside is returned to the blower's inlet by forced circulation continuously. On one hand, a small amount of fresh air is provided, on the other hand, the exhausted air is led into the air pack between the double plastic layers before being discharged into the open air. This is to maintain the temperature in the fermentation chamber. During the endless air circulation, the compost temperature rises gradually until it reaches the designated temperature. There is no need of extra heating. The whole process takes about 10-12 days.

MECHANICAL COMPOSTING

Barrel composting is a type of mechanical composting. A method of barrel composting is devised by Baker, is as follows: The octagon-shaped barrel is 16m long and 3.8m across, with five circular steel bands spaced along its length on the outside. The support frame is made of steel, with the eight flat surfaces of marine ply. Barrel capacity of 40 tonnes is sufficient to produce compost for 55m2 of cropping areas.

Power is supplied by 5.6 kW motors driving two hydraulic pumps, in turn to two hydraulic motors, each with gear boxes on inverted heavy duty Thornicraft differentials. The barrel is mounted on ex-aircraft tyres. Speed is variable from one revolution per hour to one revolution per minute. Normal operating speed is one revolution every eight minutes.

Air system: A unique air system features ducting built within the structure of the barrel, consisting of vented plywood plates across each corner of the octagon. The pressurised air distribution system runs the length of the barrel and is designed so that as the barrel revolves, air enters only from ducts along the base and is forced up through the compost.

Water: The water system consists of four main rails running the length of the barrel, with 12 misting nozzles along each rail. As the barrel revolves, only the top two rails at any time are in operation, discharging water at 280 kPa pressure. Water is stored in a 5000 L reservoir, which in winter is heated to 44°C.

Compost is based on wheat straw, requiring approximately 350 bales per fill. Activator ingredients consist of:

- cattle manure

- poultry manure

- cotton seed meal

- cotton seed hulls

- gypsum

- lime

with the aim of having a nitrogen content of 1.5 per cent entering peak heat. Materials are kept clean and dry and the manure screened to remove any objects that may damage equipment. Individual ingredients are measured and mixed in a concrete agitator for transport and dispensing at the point of filling the barrel.

Loading the Barrel

Straw is pre-wetted in batches of five bales (each of 20 to 25 kg) for four minutes in a dip tank. Bales are allowed to drain, leaving them with approximately 50 per cent of total water requirements. They are then carried by an air operated lifting station on to a conveyor where the bale ties are cut and counted. As the straw moves along the conveyor it is mechanically loosened, then fed into a Gehl forage harvester which cuts it to 4 to 5 cm.

The cut straw enters a hopper where it is mixed with the activator at the rate of 55 L per bale, so that the activator adheres to the moist straw as it enters a blower, which lifts the mixture up and into the barrel.

Composting Cycle

| Day 0 |

after filling the barrel is closed and rotated for 45 to 60 minutes so that the compost is levelled and mixed; at the same time 5000 L of water is added. |

| Day 1 |

1600 L of water is added and the compost is rolled and steamed for eight hours. Steam is introduced through the water system. |

| Day 2 |

all water jets are removed, their spray patterns checked and cleaned if necessary. 50 kg of ammonium nitrate (34 per cent nitrogen) dissolved in 2000 L of water is then added to the compost. |

| Day 3 to 6 |

each morning 1600 L of water is added to the compost as it is rolled and aired. The compost is further rolled and aired each afternoon. |

| Day 7 |

the moisture content of the compost is tested and adjusted to 70 to 72 per cent. |

| Day 8 |

barrel emptied. |

Four central hatches are opened and the barrel is rotated intermittently so that the compost falls from the hatches on to a drag elevator, to a transfer belt, then on to a filling belt.

Trays are fed along a conveyor underneath the barrel, filled, stacked and transferred to the peak heat room.

The barrel is not completely self-emptying, but only the last 500 to 600 kg of a total of 40 tonnes has to be emptied manually.

For composting by any method the size of the heap is a very important factor. If it is large, then the compactness will be less and aerobic conditions will be there. Penetration of the air is affected by the difference of the external and internal temperature and by the compactness of the pile material, i.e., in summer less ventilation is needed and the pile must be kept smaller with loose, long straw. The side must be trampled down to prevent free penetration of air, which would carry away the ammonia and lower the temperature.

In Barrel system air was forced through the compost for making an aerobic and uniform compost. The entire Phase I cycle from straw wetting to Phase II was eight days. This system was later abandoned because of cost and compost quality.

In the mid 1980's in Austria and in Switzerland traditional Phase I composting systems were developed. These farms were very similar and both were built enclosed for the purpose of highly controlling odour emissions. All aspects of composting were carried out indoors. All process, air streams were treated using a biofilters before discharge. Materials were moved around computer controlled robot cranes during pre-wetting, with Phase I being carried out in pressed block of compost with ventilation. Capital and operating costs for these farms were high resulted into closing of the farms.

Generally, in the low temperature composting there was a short pasteurization phase at about 60°C for a few hours, and then about a week of composting at around 47°C. The lower temperature composting not only controls odour but also saves raw ingredients substantially and the fostering of the thermophilic fungi populations which make compost selective and promote mushroom growth.

In general, low temperature methods did not produce compost equivalent to traditional methods, as these materials had poorer bulk densities and produced lower yields per bed surface area. In commercial practice, Vestizens found low temperature Phase I composts gave poorer yields and were less selective than enclosed composting methods having a high temperature (around 80°C) phase, Miller found selectivity to be excellent in their low temperature composts reported for tunnels using pull nets, where the nets could interfere with uniform air flow. In commercial practice Gulliver found enclosed high and low temperature Phase I compost to be the same in terms of yields, and that both enclosed methods were inferior to traditional methods.

In the past few years, commercial enclosed composting tends to follow the Italian practice of high temperature Phase I followed by a fairly standard Phase II in tunnels. Laborde worked on enclosed composting which is in recent practice. Utility of bunkebeen demonstrated by Overstijns. Modifications in enclosed composting done by different workers made commercial growing successful.

Very high composting temperature of around 80°C tend to kill most microbes within compost, including all of the fungi and actinomycetes and most of the bacteria. Phase I tunnels can allow temperatures throughout the composting mass to become uniformly hot enough to eliminate populations required to complete Phase II. Currently three strategies are being used to deal with this problem. Materials from Phase I tunnels can be re-inoculated at the beginning of Phase II, Ventilation can be used in the tunnel cooler than 60°C thereby maintain desired population 5 to 10% of the material. Phase I can also be carried out in a bunker where the top and side layers of the compost will loose sufficient heat to prevent the entire composting mass to reach very high temperatures, and this cooler compost is then remixed with the hotter compost as an inoculant on removal of the compost from the bunker.

It is better to have the basic ideas of ideal composting to enable to have the better results in enclosed methods of composting. According to Miller the goals to be achieved in compost, ready for spawn run and cropping includes are:

- Suitable bulk density i.e., wet weight bulk density of an approximately 550 to 600 kgm3, related to straw softening and other structural charges.

- Modification of plant materials so that nutrients are made available to the mushroom crop.

- Biological removal of readily available initial nutrients to avoid overheating and competitor growth either Phase II or spawn run.

- Building up of an appropriate bio-mass and a variety of microbial products, some of these can serve as a nutrient source for the mushroom.

- Establishment of selectivity, i.e., the composting promotes the growth of Agaricus over competitor organisms. Selectivity is based on nutrition, structure, and other factors.

- Modification of compost structure, so that it holds more water within the straw.

- Building up of compost moisture content to serve as a water reservior for the mushroom crop.

- Conversion for nitrogen into stable organic forms, making nitrogen available to Agaricus but not prone to further ammonification by competitors.

Selection of Enclosed Composting: Method of enclosed composting is determined according to the site. In Western Europe, where composting yards are very large, odour and ammonia emission should be controlled. Phase I is carried out in completely enclosed tunnels and process air is treated by air washers and bio-filters before discharge. The places where the rules on atmospheric emissions are not very strict, bunker systems are appropriate, while open bunker systems will permit some emissions to the atmosphere odour will be less compared to the conventional open air composting. Places, where adverse weather conditions exist and make traditional composting difficult, enclosed Phase I system should be followed.

Enclosure should be decided in local community depending on economies and local community standards. Enclosed Phase I methods can save money in the areas of lower raw material losses, smaller land requirements, shorter process duration, lower labour cost and consistency of mushroom production.

Bunker systems rely on keeping outer zones of the compost cool enough (less than 60°C) so that thermophilic fungi and actinomycetes which are important to Phase II are not killed. For this, retaining walls should not be heavily insulated as some level of ambient airflow across the top of composting mass is required. Bunker system will cost less than a tunnel system.

Tunnel systems which achieve uniformly high temperatures require the compost to be re-inoculated with beneficial micro-organisms, so that Phass II can be carried out. In commercial practice, inoculation of the Finished Phase I material is made with a finished Phase II compost. At this time, inoculants for high temperature Phase I materials are in the development stage.

Commercially, in bunker system about 25% of the Phase I composting mass should be maintained below 60°C, so that remixing the entire mass at the start of Phase II will provide sufficient self-inoculation to the remainder of the compost. This mixing of re-inoculation gives the variable result as compared to using a specific inoculant. Better process monitoring and control of the bunker Phase I might allow better and more consistent development of populations suitable for self-inoculation during the Phase I process.

The practice of enclosed composting is becoming popular, improvement will further make the mushroom growing more successful. While low temperature single phase methods of preparing compost can be used to grow mushrooms. High temperature Phase I appears to be more advantageous in producing high yielding commercial composts.

Futher research towards enclosed composting with environmental control may cost less than the traditional method of composting in future.

It is necessary to chop the straw in order to facilitate the retention of heat and moisture both during the composting period and during the sweating out process. Chopped straw is also easier to handle. Long straw binds and is laborious to mix. Chopped straw compost is better than straw which is partially chopped or not chopped at all. The length of the composting period is influenced: (i) by the nature and subdivision of the fibrous material, and (ii) by the aeration of the compost pile. The size of the pile also affects the composting and accordingly the yield. The smaller piles have a relatively large surface exposure to the atmosphere, so that almost all parts of the piles receive good aeration, reverse was the condition in the case of a large pile. Good aeration is also obtained by placing a ventilatory in the centre of the large pile. When preparing the compost with straw it is necessary to compress the straw in order to prevent too much aeration from drying out and cooling in the straw compost, whereas with closely packed material it is necessary to make special provision for aeration. When good aeration is provided manure can be composted in seven days. The CO2 concentration at a point in the pile is more dependent on the width of the pile than the height.

During composting, moisture is also very important. If the chemical composition of a compost is good, the course of the composting process depends upon the dry matter, water, and air ratio in the compost. This ratio is highly dependent upon the moisture content and the force with which the compost is compressed.

If moisture is low during composting, bacterial decomposition is arrested and nitrogen escapes as ammonia and other volatile forms of nitrogen. At a very high moisture level, unaerobic conditions set in and bring down the speed of the decomposition. Depending upon the nature of the composting material the moisture level can be adjusted. If the compost is wet (more than 70 per cent) there is a low supply of oxygen. Due to the slow activity of microorganisms the temperature rises slowly and with the short supply of oxygen the anaerobic condition will set in and carbon dioxide will be more. If such condition is obtained in the larger part of the pile the quality of the dry matter will be affected. The oxygen concentration in the heap has a great influence on the liberation and fixation of ammonia. The optimum moisture content at which the mycelium grows best is 68-70 per cent. If the compost is very dry (less than 60 per cent) at spawning the mycelium growth is very thin.

The interval between the turns is also important and is governed by the nature of the material. The object is to turn as soon as there is a risk of an anaerobic area development. The length of the composting period is very important although the determination of the length is an art. The experienced grower considers the composting is complete when the manure has a dark colour and when the tensile strength of the straw in the manure is low (indicating that the straw can absorb and retain water).

For a lay person the compost is ready when it has the following qualities:

(a) The heap should have a light brown appearance.

(b) The straw should be neither too long nor too short.

(c) The heap should have lost the smell of ammonia and have a rich mushroom aroma.

(d) When squeezed tightly in the hand the moisture should be released in the form of only a little dampness and the compost fragments should only just bind together.

The quality of a mushroom compost depends on:

(a) The nature and quality of the basic material.

(b) Organic and inorganic supplements.

(c) The management of the compost during the composting period.

SPAWN AND METHODS OF SPAWNING

Spawn is the mushroom seed, comparable to the vegetative seed in crop plants. It is merely the vegetative mycelium from a selected mushroom grown in a convenient medium and the particular strain of mushroom selected, decides the type of mushroom the spawn would produce. The success of mushroom cultivation and its yield depend to a large extent on the purity and qualityof the spawn used. In the seventeenth century when mushroom growing started, mushroom growers used to plant horse manure beds with horse droppings containing living mycelium which they called "spawn". Given here are some of the many improvements that have been done in spawn making from time to time.

Virgin Spawn: When the spores of the mushroom fungus fall on suitable substrate and the environment is also suitable, they germinate and form a mat of mycelium. This is dug out and used as spawn, and is known as "Virgin spawn". This type of spawn was used in France and exported to other countries.

Flake Spawn: When the beds are fully covered with mycelium before a crop of mushroom appears, the compost is collected, broken, dried and used fresh to inoculate other new beds. This type of spawn is called flake spawn.

Brick Spawn: A mass consisting of horse and cow dung manure and loam is mixed with water, tapped out in a layer two inches thick and cut into pieces when half dry. These pieces are then inoculated with the old spawn by making a hole in each, and after the spawn grows through the entire piece, it is dried and sold as brick spawn. Mycelium from tissue cultures is inoculated into the bricks and thus a vastly improved laboratory type of brick spawn is prepared.

The inoculum for the aforementioned spawns were prepared by inoculating specially prepared bottles of sterilised horse manure, tobacco stem or other medium with the germinated spores of the mushroom. However, these spawns are not in use at present.

Grain Spawn: Another type of spawn that has been developed is, spawn using grain (wheat or rye) as a base. The grain spawn is now almost universally used. The larger grains carry a greater reserve of food material per grain for mushroom mycelium so the spawn prepared with larger grains can withstand adverse conditions such as poor composting, etc. The small grains provide more points of inoculum per gram of spawn, so the spawn prepared with smaller grains will cover the compost sooner.

Different workers reported different grains for making grain spawn. Stoller preferred rye grain to sorghum for avoiding sectoring and advised the use of 6 g of gypsum and 1.5 g chalk per pound of grain to avoid the clumping of grains. Stoller got a faster growth of mycelium on hulled grain and cotton seed meal while buck wheat and wheat bran showed poor growth. San Antonio advised that cereal grain can be the only common substrate for commercial spawn production. Munjal recommended the use of jowar grain for the preparation of Agaricus bisporus spawn. Kumar reported that jowar gave better growth of mycelium after mixing 2 per cent gypsum and 6 per cent CaCO3 with the boiled grain by weight. Hu, used shell powder, starch, compost powder and grain hull powder for making granular spawn in Taiwan.

ADVANTAGES OF GRAIN SPAWN

(a) It is easier to plant than manure spawn, especially in the tray system where for spawning it can be scattered over the surface without unstacking and restacking the tray. Thus, labour is saved. With the standard shelves system, it is usually planted in the compost because of the quicker drying out of the compost surface layer as compared with the tray system of growing.

(b) Grain spawn run is faster and growers can save a few days for starting production.

DISADVANTAGES OF GRAIN SPAWN

(a) Due to its susceptibility to green moulds, the beds cannot be spawned at, as high a temperature as with manure spawn.

(b) It does not ship well and cannot be kept by the growers once it has been removed from the culture container.

(c) Grain spawn cannot be kept for any length of time in cold storage.

(d) Rats and mice dig up the beds to get the grain.

(e) It is not as resistant to adverse conditions as are the other types.

METHODS OF PREPARATION OF GRAIN SPAWN

Agaricus bisporus