DISPOSABLE PLASTIC SYRINGES, NEEDLES & NEEDLE TUBE PLANT

INTRODUCTION

This project purposes to install entire equipments needed for an integrated Disposable syringe plant. This means that the project aims at mfg. all the components of a syringe within the plant and assemble them into a complete syringe for sale under its own reliable brand name. To make its product economical, the project does not intend to import seamless extrunded tubes of miniature diameters which happen to be quite expensive.

Disposable needle is widely used by doctors for injection purpose with the help of syringes. With the increase in population in our country, requirement of medicine and injections has increased. For more strength of people more number of needles are required with syringes. Tablets or capsules also pay a great role in the life of human beings but injections are also to some extent. For quick relief, needles are used by surgeons, dental surgeons, Veterinary Surgeons, and by the breeders in the poultry farm, where the farm birds are periodically injected against epidemics. To avoid wastage and to reduce cost by quantity of syrup, needles find a wide scope with the veterinary surgeons/doctors.

With the development of pharmaceutical industries the use of syringes and disposable needles will also develop.

Disposable needles are becoming more popular in the medical world due to its lower cost and higher accuracy. Plastic can be used in place of metal without any problem. The procedure is also relatively easy and cheaper.

B.I.S SPECIFICATION

IS : 3317 - 1983

IS : 6525 - 1972

Above Specifications may be obtained from Bureau of Indian Standards,

9, B. S. Zafar Marg,

New Delhi - 110 002.

NOTE: - The use of the ISI Certification Mark is governed by the provisions of the Indian Standards Institution (Certification Marks) Act and the Rules and Regulations made thereunder. The ISI Mark on products covered by an Indian Standard conveys the assurance that they have been produced to comply with the requirements of that standard under a well-defined system of inspection, testing and quality control which is devised and supervised by ISI and operated by the producer. ISI marked products are also continuously checked by ISI for conformity to that standard as a further safeguard. Details of conditions under which a licence for the use of the ISI Certification Mark may be granted to manufacturers or processors, may be obtained from the Indian Standards Institution.

MARKET SURVEY

Syringe barrel & piston alongwith needle-base and needle cover etc., are the injection moulded items that go into the assembly of a complete syringes injection moulding of plastic components is effected in a properly designed & constructed mould.

All basic designs of injection moulds have the cold-runner two-plate concept, for parts that require large gates. This results in the sprue, runners & gates solidification with the plastic melt material lying in the cavity. The 'shot size'& clamp tonnage of the injection moulding m/c are decreased by the size of the sprue and runners. Us of one type of mould depends on the various factors that influence product qualities

.

It is the flow property of the plastics in question that determines whether or not it can be injection moulded. Even under optimum moulding conditions, very long flow paths large surface areas of excessively thin sections may result in short shots. But, parts like syringe barrels, pistons and needle cover etc., are the most suitable sizes for injection moulding without difficulties.

The wall thickness is governed mainly by functional requirements, the size of the moulded part & length of flow path.

PRODUCTION OF SYRINGES AND NEEDLES

| Years | Production (Lakh Nos.) |

| 1986-87 |

1185 |

| 1987-88 |

1210 |

| 1988-89 |

1290 |

| 1989-90 |

1380 |

| 1990-92 |

1570 |

| 1991-92 |

1770 |

| 1992-93 |

1900 |

| 1993-94 |

2220 |

| 1994-95 |

2455 |

| 1995-96 |

2710 |

PRESENT MANUFACTURERS OF DISPOSABLE NEEDLES

1. M/s. Hindustan Syringes

& Medical Dewces Ltd.

GL-3, Ashoka Estate,

24, Barakhamba Road,

New Delhi - 110 001

Tel.: 011-3314785, 3313945

Fax: 91-11-3313569

2. M/s. Apollo Surgical Co.

Shop No. 8, Raheja Complex,

834, Mound Road,

Chennai - 600 002

Tel.: 044-835886

PROPERTIES

The various components of Hypodermic needle shall be made from the following materials shown against each.

- The Hub shall be made from free cutting brass wire.

- Stillete - Stillete shall be hard drawn brass wire or stainless steel wire and supplied one for each needle.

Shape and Dimensions of Needle

The needles may have other diameter length combination as agreed to between the purchaser and the supplier.

The nominal diameter of the needle shall be designated by a number closely corresponding to the outside diameter of the acannula.

MANUFACTURING PROCESS

The needle tube is seamless. These tubes are manufactured by extrusion process. The size of the tubes used for the manufacturing of needles have a range of 14 swg to 26 swg.

Seamless stainless steel tubes are purchased from the market and then it is cut into the required length. After cutting the edges are smoothened by grinding operations. After the smooth grinding one end of the needle tube is ground and into a slanting shape and the slanting tip is also subjected to smooth grinding. All these operations are done with the help of automatic needle making m/c with abrasive cut off system. After all these operations, the needle tube is ready for fixing the hub. The manufacturing process of hub is very simple. For this purpose injection moulding is used. The process can be automatic or semiautomatic. The plastic material i.e. HDPE Compound with all additives (like plasticizers, stabilizer, fillers) are fed into the injection moulding machine. The moulds which are used in the injection-moulding machine have the shape of the hub. The plastic compound is heated and the required shape is obtained in the molten stage, followed by cooling at a proper rate.

Then the finished needle tube is fixed to the hub, which is in the hot stage. The hub is properly fixed due to the shrinkage occurred in the hub when it is cooled. After fixing, the needle is sterilized in the sterilizing unit. The sterilized needle is put into the plastic cap and then is packed in the plastic covers. Then the needle is ready for supply.

Sterilization

For needle sterilization gaseous sterilants are used, because plastic hub cannot withstand the temperatures and moisture of steam. Sterilization is exposure to radiation. The main practical requirement is that the gas selected should allow safe handling and that its residues should volatilize relatively quickly if absorbed by components of the arbode sterilized. Ethylene oxide satisfies most of these requirements and as the most frequent choice. The ethylene oxide used for sterilization is in diluted form.

The disposable needles being hollow are made from stainless steel drawn capillary tube (cannula). The manufacture of drawn capillary tube is a medium sized unit while the disposable needle making out of this tube is a small unit and is reserved exclusively for small scale.

The needle tube is made from seamless stainless steel drawn tubing. The needle tubes are imported from U.K., West Germany, U.S.A., Switzerland and Japan. The supplies are usually in length of 0.5 m to 3 meter.

Care of Disposable Plastic Syringes

- A fresh Disposable plastic Syringes must be used for each and individual injection.

- It is essential to keep plastic syringes for injection from those used for aspiration.

- Do not talk, cough, or squeeze over a sterile plastic syringes.

- Sterile plastic syringes must be placed in sterile conditions.

MANUFACTURING PROCESS FOR PLASTIC PARTS

The manufacturing process involves die design, material selection, blending of plastic resins with other additives, mould/die construction, heat treatment and inspection, before use on the automatic injection moulding m/c. These details have already been described earlier.

However, compounded to correct formulation plastic is used as a raw material in an injection moulding machine to form barrel, piston/plunger and needle cover of a disposable plastic syringe conforming to the specifications developed by Bureau of Indian Standards or other international standards.

The injection mould barrel & piston is finished mechanically & calibrated to indicate quantity of injecting drug drown in the barrel.

Finally, the plastic parts are tested as per given guidelines of international standards before safe packaging for despatch.

PRESENT MANUFACTURERS OF DISPOSABLE SYRINGES

1. M/s. Core Healthcare Ltd.

Core House, Near Parimal Garden,

Ellisbridge,

Ahmedabad - 380 006

Tel.: 079-446771, 445726

Fax: 91-79-6420239

Telex: 0121-6081

2. M/s. Goldmine Polymers Ltd.

B-22, 23, Sector-VI,

Noida - 201 301

Tel.: 0118-526355, 526356

Fax: 91-118-526355

Telex: 0598-242 NEAN IN

PRESENT MANUFACTURERS OF STERILIZED DISPOSABLE SYRINGES

1. M/s. Hindustan Syringes & Medical Devices Ltd.

GL-3, Ashoka Estate,

24, Barakhamba Road,

New Delhi - 110 001

Tel.: 011-3314785, 3313945

Fax: 91-11-3313569

2. M/s. Amit Electro-Plast

431, Sarvodaya Com. Center,

Salapose Road,

Ahmedabad - 1.

Telephones No.: 23553, 23255.

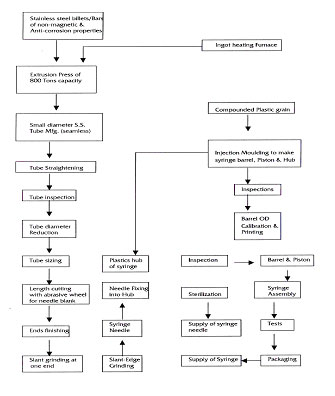

PROCESS FLOW DIAGRAM

Mfg. Hypodermic Needles & Disposable Syringes

SUPPLIERS OF PLANT & MACHINERIES

Injection Molding Machine

1. M/s. Cincinnati Milacron Pvt. Ltd.

Plot No. 14/16, Phase - I,

GIDC Vatva,

Ahmedabad - 382 445

Tel. : 073-5830112, 5830125

Fax : 91-79-5830578

2. M/s. Boolani Engineering Corporation,

Prabhadevi Industrial Estate,

402, Veer Sawarkar Marg,

Mumbai - 400025.

Tel.: 022-4302826

Fax: 91-22-4229875

Suppliers of Moulds

1. M/s. Plasto Tools

E-14 A-Ansa Industrial Estate,

Saki-Vihar Road,

Mumbai - 400 072

Tel.: 5783143

Fax: 91-22-8360351

Telex: 011-78412 PMCO IN

2. M/s. Everfine Industries

I-1, D.S.I.D.C. Industrial Complex,

Rohtak Road, Nangloi,

Delhi - 110 041

Tel.: 011-5472508

Fax: 91-11-7141267

SUPPLIERS OF IMPORTED RAW MATERIAL

Stainless Steel Tube

1. M/s. Schodllar Works KG,

5374, Hellaen Thal

(Eifel) West Germany.

2. M/s. San Sho Trading Co.,

36, Somozaki Shinchi,

3, Chome kita ku,

Osaka, Japan.

SUPPLIERS OF PLASTICS (HDPE, PP, POLYSTYRENE ACRYLICS ETC.)

1. M/s. Revex Plasticisers Pvt. Ltd.

A-72, Industrial Area, Phase-I,

Naraina, New Delhi - 110 028

Tel.: 011-536039, 535256

Fax: 91-11-5416514

2. M/s. Polypropylene (India)

64/1, K.K. Roy Choudhury Road,

Sakhar Bazar, Barisha,

Calcutta - 700 008

Tel.: 033-777345, 777350

Fax: 91-33-4781878

NEEDLE SURFACE TREATMENT CHEMICALS SUPPLIERS

Sodium Hydroxide

1. M/s. D.C.M. Shriram Consolidated Ltd.

Kanchanjunga Building,

5th Floor, 18, Barakhamba Road,

New Delhi - 110 001

Tel.: 011-3316801

Fax: 91-11-3318072

Other Sodium Compounds

M/s. Chemtex Corporation

33, 7th Floor, Brabourne Road,

Calcutta - 700 001

Tel.: 033-2426840, 2424546

Fax: 91-33-2423329

PLANT ECONOMICS

| Rated Plant capacity |

= |

20000.00 Nos./day |

| |

|

PLASTIC SYRINGES NEEDLES |

Basis

| No. of working days |

= |

25 days/month |

| No. of shifts |

= |

1 per day |

| One shift |

= |

8 hours |

LAND & BUILDING

| 1. |

Total Land area 4000 sq.mts. |

|

| |

@ Rs. 200/ - per sq.mts. |

Rs.8,00,000.00 |

| 2. |

Buildings |

Rs.22,00,000.00 |

| |

TOTAL |

Rs.30,00,000.00 |

PLANT & MACHINERY

| 1. |

Stainless steel tube Extrusion Press 1000 tonnes capacity, with 1200 HP drive covrsd.type cold SS B |

Rs.1,10,00,000.00 |

| 2. |

Die-casting M/C 60 CT complete with melting furnace, electronic control panel, finishing-line eqpts.-hub. |

Rs.10,00,000.00 |

| 3. |

Automatic abrasive wheel-cutter for tube and grinding, slant grindcutter slant edge rounding systems etc. |

Rs.30,00,000.00 |

| 4. |

Injection moulding M/C for making plastic syringe barrels & pistons & hub. Cap: 60 gms/shot automatic. |

Rs.15,00,000.00 |

| 5. |

Automatic Assembly line & Sterilizing plant |

Rs.10,00,000.00 |

| 6. |

Testing Equipments & Instruments |

Rs. |

5,00,000.00 |

| 7. |

Dies/Moulds, Tools, Fixtures, DG. Set, Material handling Equipments & Pack- aging equipments and tool room |

Rs.20,00,000.00 |

| |

TOTAL |

Rs.2,00,00,000.00 |

OTHER FIXED ASSETS

| 1. |

Office equipment, furniture plus other equipment & accessories |

Rs.1,00,000.00 |

| 2. |

Installation costs for water, electricity, fuel etc. |

Rs.20,00,000.00 |

| 3. |

Pre-operative & preliminary expenses |

Rs.20,00,000.00 |

| 4. |

Technical know how, designning and consultancy etc. |

Rs.9,00,000.00 |

| 5. |

Transportation, Taxes etc. |

Rs.10,00,000.00 |

| 6. |

Contingences |

Rs.10,00,000.00 |

| |

TOTAL |

Rs.70,00,000.00 |

FIXED CAPITAL

| 1. |

LAND & BUILDING |

Rs.30,00,000.00 |

| 2. |

PLANT & MACHINERY |

Rs.2,00,00,000.00 |

| 3. |

OTHER FIXED ASSETS |

Rs.70,00,000.00 |

| |

TOTAL |

Rs.3,00,00,000.00 |

WORKING CAPITAL REQUIREMENT/MONTH

RAW MATERIALS

Rs.4,000.00

| 1. |

Stainless Steel Ingots/Billets 51 MT. @ Rs. 70,000/- per MT |

35,70,000.00 |

| 2. |

H.D.P.E. Granules for hub and cover 300 Kg. @ Rs. 60/- per Kg. |

Rs.18,000.00 |

| 3. |

Pretreatment che. (sodium metasilicate sodium pyroph. sodium hydroxide earlier 50 lit. @ Rs. 200/- per lit. |

Rs.10,000.00 |

| 4. |

Acetone for hub surface preparation (cleaning) 40 litres @ Rs. 100/- per lit. |

| 5. |

Chemicals for Sterilizing |

Rs.48,000.00 |

| 6. |

Packaging Materials. |

Rs.50,000.00 |

| 7. |

Miscellaneous Stores |

Rs.1,50,000.00 |

| |

TOTAL |

Rs.38,50,000.00 |

SALARY & WAGES / MONTH

| 1. |

Manager Works |

1 No. |

Rs. |

15,000.00 |

| 2. |

Plastic Technologist |

1 No. |

Rs. |

5,000.00 |

| 3. |

Mechnical Engrs. |

3 No. |

Rs. |

30,000.00 |

| 4. |

Skilled Workers |

30 No. |

Rs. |

45,000.00 |

| 5. |

Unskilled Workers |

20 No. |

Rs. |

20,000.00 |

| 6. |

Clerk/Typist |

2 No. |

Rs. |

3,000.00 |

| 7. |

Peon/Chowkidar |

4 No. |

Rs. |

5,000.00 |

| 8. |

Supervisors |

6 No. |

Rs. |

12,000.00 |

| 9. |

Accountant/Receptionist |

2 No. |

Rs. |

6,000.00 |

| 10. |

Sales/Pur./Stores Staff |

Rs. |

19,000.00 |

| |

|

TOTAL |

Rs. |

1,60,000.00 |

| |

Plus perks @ 20% p.a. |

|

Rs. |

32,000.00 |

| |

|

TOTAL |

Rs. |

1,92,000.00 |

UTILITIES AND OVERHEADS

| 1. |

Power Consumption of 400000 Kwatt hrs @ Rs. 3.00 per Kwatt hr. |

Rs. |

12,00,000.00 |

| 2. |

Water Consumption of 500 KLs @ Rs. 2.00 per KL |

Rs. |

1,000.00 |

| 3. |

Stationery, Postage, Telephone etc. |

Rs. |

9,000.00 |

| 4. |

Conveyance & Transportation etc. |

Rs. |

10,000.00 |

| 5. |

Publicity & Sales Promotion |

Rs. |

30,000.00 |

| 6. |

Miscellaneous |

Rs. |

1,50,000.00 |

| |

TOTAL |

Rs. |

14,00,000.00 |

Total load is 2200 Kwatts

TOTAL WORKING CAPITAL/MONTH

| 1. |

RAW MATERIAL |

Rs. |

38,50,000.00 |

| 2. |

SALARY & WAGES |

Rs. |

1,92,000.00 |

| 3. |

UTILITIES & OVERHEADS |

Rs. |

14,00,000.00 |

| |

TOTAL |

Rs. |

54,42,000.00 |

- WORKING CAPITAL FOR 3 MONTHS Rs. 1,63,26,000.00

- MARGIN MONEY FOR W/C LOAN Rs. 40,81,500.00

COST OF PROJECT

| TOTAL FIXED CAPITAL |

Rs. |

3,00,00,000.00 |

| MARGIN MONEY |

Rs. |

40,81,500.00 |

| TOTAL |

Rs. |

3,40,81,500.00 |

TOTAL CAPITAL INVESTMENT

]

| TOTAL FIXED CAPITAL |

Rs. |

3,00,00,000.00 |

| TOTAL WORKING CAPITAL FOR 3 MONTHS |

Rs. |

1,63,26,000.00 |

| TOTAL |

Rs. |

4,63,26,000.00 |

COST OF PRODUCTION/ANNUM

| 1. |

Working Capital for 1 year |

Rs. |

6,53,04,000.00 |

| 2. |

Interest @ 18.00% on T.C.I |

Rs. |

83,38,680.00 |

| 3. |

Depreciation @ 6.50% on buildings |

Rs. |

1,43,000.00 |

| 4. |

Depreciation @ 25.00% on Plant and Machinery |

Rs. |

50,00,000.00 |

| 5. |

Depreciation @ 20.00% on office equipment & furnitures |

Rs. |

20,000.00 |

| |

TOTAL |

Rs. |

7,88,05,680.00 |

TURN OVER/ANNUM

| 1. |

By sale of 540 MT Seamless Stainless Steel tube (hypodermic needle - grade) @ Rs. 135000/- per MT |

Rs. |

7,29,00,000.00 |

| 2. |

By sale of 6 million Hypodermic needles for Disposable Syringes. @ Rs. 2.5/- each. |

Rs. |

1,50,00,000.00 |

| 3. |

By sale of Scrape of Stainless Steel 12 MT @ Rs. 35,000/- per MT |

Rs. |

4,20,000.00 |

| |

TOTAL |

Rs. |

8,83,20,000.00 |

PROFIT = RECEIPTS - COST OF PRODUCTION

= 8,83,20,000.00 - 7,88,05,680.00

= 95,14,320.00

PROFIT SALES RATIO = Profit / Sales x 100

= 95,14,320.00/8,83,20,000.00 X 100

= 10.77 %

RATE OF RETURN = Operating profit / T.C.I x 100

= 95,14,320.00/4,63,26,000.00 X 100

= 20.54 %

BREAK EVEN POINT (B.E.P)

Fixed Costs of the plant are as under -

| 1. |

Interests |

Rs. |

83,38,680.00 |

| 2. |

Depreciation |

Rs. |

51,63,000.00 |

| 3. |

25.00% of salaries |

Rs. |

5,76,000.00 |

| 4. |

40.00% of overheads |

Rs. |

67,20,000.00 |

| |

TOTAL |

Rs. |

2,07,97,680.00 |

B.E.P. = FIXED COSTS/FIXED COSTS + PROFIT X 100

= 2,07,97,680.00/2,07,97,680.00 + 95,14,320.00 X 100

= 68.61 %

LAND MAN RATIO = Total land / Manpower

4000 : 69 :: 58 : 1

RESOURCES FOR FINANCE

2,40,00,000.00

| 1. |

Term loans from Financial institutions (80.00 % of fixed capital) at @22.00% p.a rate of interest |

Rs. |

| 2. |

Bank loans for 3 months (75.00 % of working capital)at @ 20.00% p.a rate of interest |

Rs. |

1,22,44,500.00 |

| 3. |

Self raised capital from even funds & loans from close ones to meet the margin money needs at a @ 24.00% p.a rate of interest |

Rs. |

1,00,81,500.00 |

| TOTAL |

Rs. |

4,63,26,000.00

|