MUSHROOMS (EOU) (CULTIVATION AND PROCESSING UNIT)

INTRODUCTION

Mushroom is an exotic source of vegetarian food. It is button shape when young, but assumes the shape of an umbrella, when fully matured. Most of its varieties are edible and form a tasty and nutrious diet.

Mushrooms are usually grown as a fall, winter and spring crop in special structures where the required temperatures can be maintained and where other necessary conditions can be provided. They are a difficult crop to produce.

USES AND APPLICATION

Mushrooms are widely used as a vegetable all over the world. This vegetable is better for health because it contains carbohydrates such as sugar, starch, cellulose, or lignin and vitamins. Mushrooms are usually grown as fall, winter and spring crop in special - structure where the required temperatures can be maintained and where other necessary conditions can be provided. Their are difficult crop is produce.

Apart from their usefulness as food, Cultivated Mushrooms have their applications-especially as condiments, as drugs, as a source of enzymes as a component of nutrient agars and potentially as animal feed.

The most important use of mushroom is as an article of food and its value as such is beyond the reach of the chemist or physiologist. In addition, mushrooms possess great value as condiments of food accessories. Mushrooms are among the most appetising of table delicacies and add great flavour to food when cooked with them.

MARKET SURVEY

In India, commercial mushroom growing was first initiated in New Delhi and Salem and later it spreads to J & K, the Nilgiris, Punjab, Haryana, Chandigarh, U.P., Maharashtra, M.P., and Gujarat.

The efforts made so far for the development of mushroom cultivation in the country are riddled with misperceptions and wrong representations. A detailed study of the developments till 1990 appeared as an article in that year's The Hindu Survey of Indian Agriculture, titled "Far from a mushrooming growth".

Mushrooms are one of the foremost items of international trade in fresh dried and processed food mainly because the rate of growth in their consumption and production is the highest among agricultural commodities internationally. India can use them as one of the prime tools for agricultural development as well as for fighting malnutrition in the country.

CANNED MUSHROOMS MANUFACTURERS/SUPPLIERS

1. M/s. IMT Farms,

30, Saraswati Soni Marg,

Laxman Chowk,

Dehradun - 248001. (U.P).

2. M/s. Excelsior Food and Chemical Industries,

A - 1, Lawrence Road,

Industrial Area,

Delhi - 110035.

3. M/s. United SA Corporation,

44, Eira Street,

2nd Floor,

Calcutta - 700001.

4. M/s. Mahadeo Fruit Processing Industry,

21 S & T Gorachand Road,

Calcutta - 700014.

5. M/s. Elmac,

20/1, BAK Mohd,

Siddique Lane,

Calcutta - 700016.

B.I.S. SPECIFICATION

Till date there is no any Indian Standard specification has developed for plant processing for Mushroom, so this report does not concern any Indian Standard Specification.

For further details please contact :

Bureau of Indian Standards,

9, B.S. Zafar Marg,

New Delhi - 110 002.

MANUFACTURING PROCESS

Mushrooms can be grown in any structure where it is possible to control ventialation, maintain a pasteurizing temperature of 130o - 145oF. For several days during sweating out, provide a humadity of 70-85% kept the temperature at 50-65oF, preferably crop is grown in specially constructed house. A good bed for mushrooms is one built in tiers, 2 feet being left between boards of each bed, and the bottom bed 6 inches off the floor. A house 1,200 sq.meter with 2 tiers 15 Ton Mushroom Production house size 40 x 30 height 12 ft. A ton of manure will produce 125 Kg mushroom.

The "short compositing method consists of two distinct phases, the first tasting six to nine days, takes place outdoors under reduced oxygen pressure and with a high ammonia concentration. The ends is built up after the addition of water. The outer part of the pile, 10 to 15 cm in diameter is compacted strongly so as to counteract the loss of ammonia by evaporation and a decrease temperature. The internal portion, losser intexture must rapidly seed,75oC and pH of over 8.5 Two turnings are made at two to three days intervals, all being finished by seventh day of composing. The second phase takes place in a pasteurization chamber of the pressure of oxygen (20 percent and good air circulation with a humidity approaching 100 percent and over temperature of OoC to 60oC. Under these circumstances, phase two taste only twelve to twenty from homs for the moment when all trees of Ammonia in the compost has gone, as fan it can be detercted by small. The pasteurization chamber, in practical growing, will be in place indentical with the are where sweating out case, phase two is accomplished by the use of the tray system.

In our further discussion we shall therefore mention only three most desirable types of beds molten order.

- Tray beds

- Sheet beds

- French beds.

Preparation of Compost :-

The best raw material for mushroom compact is manure from grained hores and a moderate amount of what-strew bedding. Manure should be fresh from the stable, and it must be composed. The mushroom lives on the products of this decomposition.

Temperature :-

A slow crop (52-55oF) will last 5-6 months whereas a fast crop (56-60oF) will last only 3 months. The cooler temperature result in somewhat larger, firmer and heavier mushrooms than the higher ones, but the total yield from either is about the same.

Harvesting :-

Mushrooms may appear 35 days after spawing. But 6-8 weeks normally elapse after casing before enough appear for picking to start. Unduly slow growth may be due to poor spawn, improperly composted manure, too many shavings in the manure low temperature, or unsuitable moisture.

MUSHROOM PRESERVATION, PICKLING, DEHYDRATION, CANNING & MARKETING

Process of preserving mushroom has for its leading object the preserventation mushroom so as to prevent the loss of thier natural flavour. This object is a accomplished in the preferred practice by subjecting the mushrooms to an evaporating operation at a temperature of from 100 to 150 degree F untill thier weight has been reduced to approximately one half through loss of water, then washing cold water to elecause and fresher the product, then dropping for a period of from 1 to 3 minutes in a both of sealding water containing citric acid and 5 pounds of salt, then coating with hot cottonseed or olive oil, and then heating for a period of farm 10 to 30 min (depending upon the bulk treated) at a temperature ranging from 212 to 250oF, actually by placing the mushroom at a temperature of about 150oF in a container which is closed and heated to effect the desired sterilizing or processing. While the forgoing treatment has been found to effect the preservation of mushroom without loss of flavour, so that the preserved product may not be distingushed from the fresh it will be varied by omitting certain operations, as washing in cold water and dropping in sealing water containing citric acid and salt and by modifying the degree of the treatment as by changing the time and temperature of the operations, or the mushroom may be sterilized in water or brine directely after being subjected to the waporating operation. It is important however that the treatment shall not drive off or causes the loss of natural Juices of the mushroom, as by the use of high or prolonged heat in effecting the evaporation of the water which is preferably driven off at a temperature between 100 to 150oF.

PICKLING & PRESERVATION

The preservation food in common salt or vinegars is called pickling. Salt, vinegars and lactic acid are the three important ingredients used in pickling. These substances when used in sufficient qualities act as preservatives either singly or collective. Spices & oil are also used. Pickling is done in two stages namely (a) curving or fermentation in drive, or salting without fermentation and (b) finishing and packing. The conditions for proper maintanance has alrady been explained earlier.

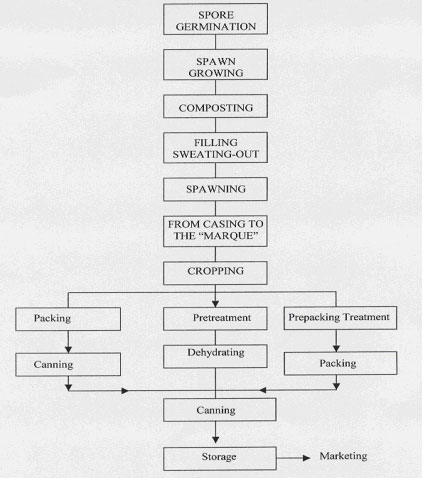

PROCESS FLOW SHEET FOR MUSHROOM

SUPPLIERS OF PLANT AND MACHINERY

M/s. A.B. Panchal & Co.,

13, Ajmeri Udyog Nagar,

Ahmedabad - 1.

M/s. B. Sen Berry & Co.

65/11, Rohtak Road,

Karol Bagh,

New Delhi-110005.

M/s. Max Flow Pumps Pvt. Ltd.,

1/1, Maucsca Road,

Gurgaon.

M/s. Anchor Hydraulics,

Khamats Lane,

By Culla,

Bombay-27.

RAW MATERIAL SUPPLIERS

M/s. Baroda Chemical & Fertilizers,

Makarpura Industrial Estate,

Baroda-10.

M/s. Vandana Fertilizers Pesticides,

New Sabji Mandi,

Hissar.

M/s. Govdow Chemical & Pharmaceutical Co.,

5, Sir, Manakjee Mehta Road,

Poona-1.

M/s. Agra Fertilizer Ind.

Gurki-Mandi, Fatehpur Sikri,

Agra (U.P).

CANNER'S EQUIPMENT

M/s. Delhi Industries,

4, Pahar Ganj,

New Delhi - 55.

M/s. Vishan Dass Raj Kumar,

242, Azad Market,

New Delhi-6.

Cans:

M/s. Bottles & Containers Industries,

Hoechst House, 3/1 Asaf Ali Road,

New Delhi-2.

M/s. Mulakh Raj & Co.,

204, Azad Market,

New Delhi-6.

PLANT ECONOMICS

Rated Plant capacity = 2.00 TON/Day

LAND & BUILDING

| 1. |

Land |

Rs. |

10,00,000.00 |

| 2. |

Building |

Rs. |

59,00,000.00 |

| |

TOTAL |

Rs. |

69,20,000.00 |

PLANT & MACHINERY

0

| 1. |

Washing tank (SS)(255 x 45 x 60 Cm3) |

10 No. |

Rs. |

80,000.00 |

| 2. |

Vacuum Drier Cap : 200 Kgs/hr. |

3 No. |

Rs. |

6,00,000.00 |

| 3. |

Steam Jacketed Kettle Cap: 1000 lts. vol. |

4 No. |

Rs. |

1,00,000.00 |

| 4. |

Boiler Steam 250 Kgs/hr. |

1 No. |

Rs. |

1,70,000.00 |

| 5. |

Can seamer (Automatic)Cap: 200 Cans/hr. |

4 No. |

Rs. |

80,000.00 |

| 6. |

Blender Cap: 100 Kgs/hr. |

4 No. |

Rs. |

80,000.00 |

| 7. |

Boiling Water bath Cap: 500 lits |

3 No. |

Rs. |

18,000.00 |

| 8. |

Fruit Puper Cap: 200 Kgs/hr. |

|

Rs. |

50,000.00 |

| 9. |

Autoclave for can sterilisation Cap: 300 Cans/hr. |

1 No. |

Rs. |

80,000.00 |

| 10. |

P.P. Sealer |

2 No. |

Rs. |

10,000.00 |

| 11. |

Black Polyethene trays & shelves 100 x 50 x 50 Cm3 (250000) |

|

Rs. |

60,00,000.00 |

| 12. |

Spray gun with motorised pump and Compressor |

20 No. |

Rs. |

60,000.00 |

| 13. |

Heat Convectors 2 KW |

20 No. |

Rs. |

4,000.00 |

| 14. |

Device for compressing and levelling the fertilized soil in trays and harvesting m/c |

10 No. |

Rs. |

1,50,000.0 |

| 15. |

Cooler for air cooling |

6 No. |

Rs. |

30,000.00 |

| 16. |

Preparation table (S.S) Length (5m x 1m x 1m) |

3 No. |

Rs. |

40,000.00 |

| 17. |

Weighing scall Weighing capacity. 100-500 Kgs. |

3 No. |

Rs. |

30,000.00 |

| 18. |

Laboratory testing equipments |

|

Rs. |

60,000.00 |

| 19. |

Air ionizer |

20 No. |

Rs. |

20,000.00 |

| 20. |

Process control equipments and instrumentation. |

|

Rs. |

30,000.00 |

| 21. |

Conveyor belt, Bocket elevators etc |

|

Rs. |

1,00,000.00 |

| 22. |

Miscellaneous equipments |

|

Rs. |

30,000.00 |

| |

TOTAL |

|

Rs. |

78,22,000.00 |

OTHER FIXED ASSETS

| 1. |

Office equipment, furniture plus other equipment & accessories |

Rs. |

1,00,000.00 |

| 2. |

Installation, electrification, water and commissining etc. |

Rs. |

5,00,000.00 |

| 3. |

Technical Know How |

Rs. |

1,00,000.00 |

| 4. |

Preliminary & Pre-operative expenses |

Rs. |

50,000.00 |

| 5. |

Miscellaneous |

Rs. |

25,000.00 |

| |

TOTAL |

Rs. |

7,75,000.00 |

FIXED CAPITAL

| 1. |

LAND & BUILDING |

Rs. |

69,20,000.00 |

| 2. |

PLANT & MACHINERY |

Rs. |

78,22,000.00 |

| 3. |

OTHER FIXED ASSETS |

Rs. |

7,75,000.00 |

| |

TOTAL |

Rs. |

1,55,17,000.00 |

WORKING CAPITAL REQUIREMENT/MONTH

RAW MATERIALS

| 1. |

Spawn (vegetable myceliun) gray 1 Bottle for 2 trays. |

Rs. |

3,00,000.00 |

| 2. |

Compost fertiltzer of standard formulation 650 Tons @ Rs. 1000/-MT |

Rs. |

6,50,000.00 |

| 3. |

Paddy Straw & Wheat Straw @ Rs. 50/- Quinatal 6600 Quintal |

Rs. |

3,30,000.00 |

| 4. |

Carbendazine solution & Benomyl (1 gm/lit Cone) or other pesticide/weedside etc. |

Rs. |

20,000.00 |

| 5. |

PVC films/bags to Store harvested mushroom for 7 days. 200 Kgs. @ Rs. 40/-kg. |

Rs. |

8,000.00 |

| 6. |

Spices, Oil, Vinegar and other |

Rs. |

50,000.00 |

| 7. |

Tin Cans ( 1 lb. capacity) 1,10,000 Nos @ 2/- can. |

Rs. |

2,20,000.00 |

| |

TOTAL |

Rs. |

15,78,000.00 |

SALARY & WAGES / MONTH

| 1. |

General Manager |

1 No. |

Rs. |

4,000.00 |

| 2. |

Production Supervisor |

4 No. |

Rs. |

7,200.00 |

| 3. |

Food Technologist |

2 No. |

Rs. |

6,000.00 |

| 4. |

Chemist |

2 No. |

Rs. |

4,000.00 |

| 5. |

Skilled worker |

20 No. |

Rs. |

24,000.00 |

| 6. |

Semi skilled worker |

30 No. |

Rs. |

30,000.00 |

| 7. |

Accountant and Typist |

3 No. |

Rs. |

4,800.00 |

| 8. |

Marketing executive |

2 No. |

Rs. |

4,000.00 |

| 9. |

Mechanical/Electrical |

2 No. |

Rs. |

2,400.00 |

| 10. |

Peons/Chowkidar |

8 No. |

Rs. |

8,000.00 |

| |

TOTAL |

|

Rs. |

94,400.00 |

| |

Plus perks @ 20% p.a. |

|

Rs. |

18,880.00 |

| |

TOTAL |

|

Rs. |

1,13,280.00 |

UTILITIES AND OVERHEADS

| 1. |

Power Consumption of 7500 Kwatt hrs @ Rs. 2.00 per Kwatt hr. |

Rs. |

15,000.00 |

| 2. |

Water Consumption of 2000 KLs @ Rs. 2.00 per KL |

Rs. |

4,000.00 |

| 3. |

Administrative expenses |

Rs. |

10,000.00 |

| 4. |

Fuel 1500 lits Rs. 5/- lits |

Rs. |

7,500.00 |

| 5. |

Transportation and Conveyance |

Rs. |

5,000.00 |

| 6. |

Publicity & advertisement |

Rs. |

10,000.00 |

| 7. |

Miscellaneous |

Rs. |

5,000.00 |

| |

TOTAL |

Rs. |

56,500.00 |

Total load is 41 Kwatts

TOTAL WORKING CAPITAL/MONTH

| 1. |

RAW MATERIAL |

Rs. |

15,78,000.00 |

| 2. |

SALARY & WAGES |

Rs. |

1,13,280.00 |

| 3. |

UTILITIES & OVERHEADS |

Rs. |

56,500.00 |

| |

TOTAL |

Rs. |

17,47,780.00 |

| 1. |

WORKING CAPITAL FOR 3 MONTHS |

Rs. |

52,43,340.00 |

| 2. |

MARGIN MONEY FOR W/C LOAN |

Rs. |

13,10,835.00 |

COST OF PROJECT

| TOTAL FIXED CAPITAL |

Rs. |

1,55,17,000.00 |

| MARGIN MONEY |

Rs. |

13,10,835.00 |

| TOTAL |

Rs. |

1,68,27,835.00 |

TOTAL CAPITAL INVESTMENT

| TOTAL FIXED CAPITAL |

Rs. |

1,55,17,000.00 |

| TOTAL WORKING CAPITAL FOR 3 MONTHS |

Rs. |

52,43,340.00 |

| TOTAL |

Rs. |

2,07,60,340.00 |

COST OF PRODUCTION/ANNUM

| 1. |

Working Capital for 1 year |

Rs. |

2,09,73,360.00 |

| 2. |

Interest @ 22.00% on T.C.I |

Rs. |

45,67,274.80 |

| 3. |

Depreciation @ 6.50% on buildings |

Rs. |

3,84,800.00 |

| 4. |

Depreciation @ 25.00% on Plant and Machinery |

Rs. |

19,55,500.00 |

| 5. |

Depreciation @ 20.00% on office equipment & furnitures |

Rs. |

20,000.00 |

| |

TOTAL |

Rs. |

2,79,00,934.80 |

TURN OVER/ANNUM

| 1. |

By Sale of 3,78,450 Kgs. of Canned Mushrooms at Rs. 60/- Kgs. |

Rs. |

2,27,07,000.00 |

| 2. |

By Sale of Dehydrated Mushroom 39060 Kgs. at Rs. 70/- Kgs. |

Rs. |

27,34,200.00 |

| 3. |

By Sale of Mushroom Pickles 182490 Kgs. at Rs. 90/- per kg. |

Rs. |

1,64,24,100.00 |

| |

TOTAL |

Rs. |

4,18,65,300.00 |

| PROFIT |

= |

Rs.1,39,64,365.20 |

| RATE OF RETURN |

= |

67.26 % |

| B.E.P. |

= |

35.67 % |