Linear Alkyl Benzene : A great scope in chemical business

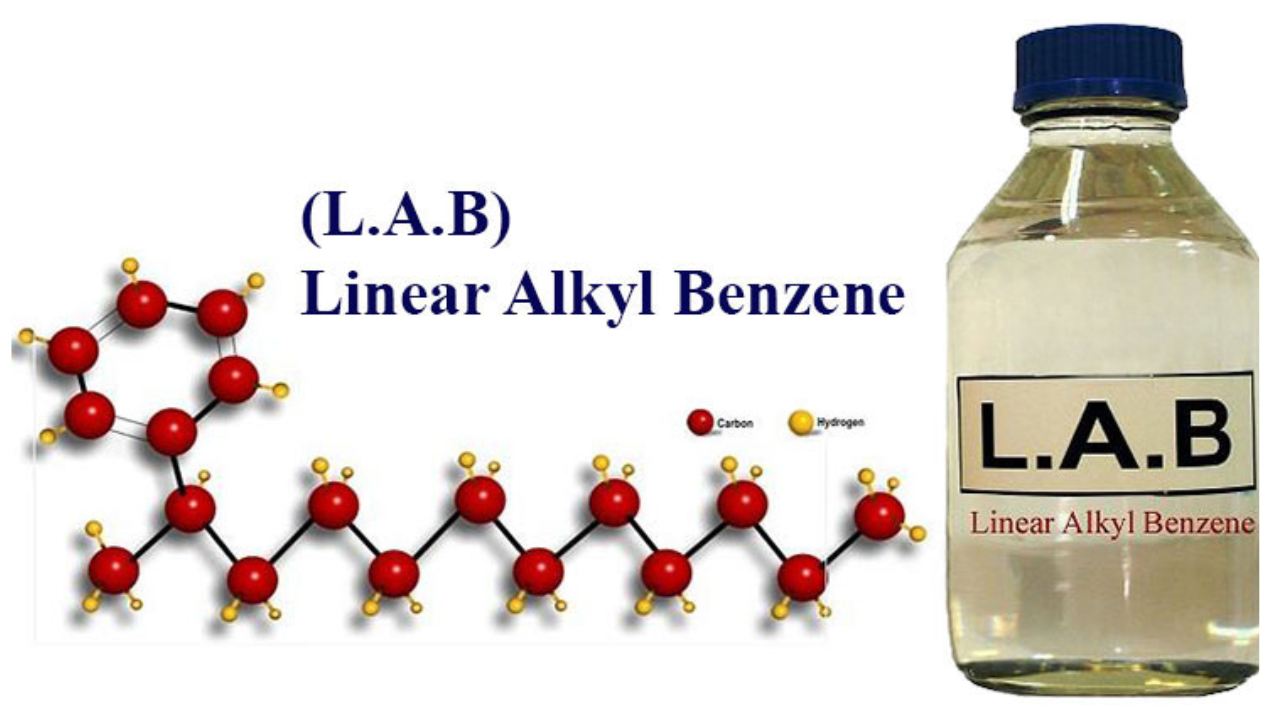

Linear Alkyl Benzene is an essential chemical used mainly to prepare surfactants, materials relevant to a whole number of applications: detergents, cleaning agents, and personal care.This is an aromatic hydrocarbon with a linear alkyl chain attached to a benzene ring. It is mainly used as a feedstock for the production of LABS—linear alkylbenzene sulfonates—one kind of surfactant. These have very good detergency properties and foaming, so LABS finds wide applications in household and industrial cleaning products.

Few Properties of Linear Alkyl Benzene are -

-

Chemical Formula: C₁₄H₂₂

-

Appearance: clear, colourless to pale yellow liquid. The exact color can vary depending on the specific alkyl chain length and the presence of any impurities or additives.

-

Solubility: Insoluble in water

-

Molecular Weight : the molecular weight of Linear Alkyl Benzene with a 12-carbon alkyl chain is approximately 162.26 g/mol.

Why should one choose Linear Alkyl Benzene chemical industry

-

Due to its excellent cleaning properties, LAB finds huge applications both in domestic and industrial detergents. With the increased demand for efficient cleaning products, LABS will continue to be in high demand.

-

LABs find applications in personal care products such as shampoos and body washes, opening up yet another strong market for LAB.

-

Increased awareness about cleanliness and hygiene is driving demand for high-quality cleaning products.

-

As urban areas expand and populations grow, the demand for household and industrial cleaning products increases, boosting LAB demand.

-

With the new technologies and more effective methods of production being introduced, LAB manufacturing has become more cost-effective. Some of the new developments in catalysts and reactors are capable of increasing yields, reducing their ecological footprint.

-

LABSs are known for their superior performance in the removal of grease and stains, thus providing an edge in competition to other surfactants.

-

High value-added surfactants can be produced from LAB in most cases, resulting in attractive profit margins.

-

The broad spectrum of applications household detergents and industrial cleaners help level out the revenue streams and reduce risks.

-

The market for cleaning and personal care products is rapidly developing and hence offers ample investment opportunities. This will be rewarding if it includes the right market conditions and the operations are working efficiently.

-

The industry is oriented to make operations greener, like low ecological footprint processes for production and development of biodegradable surfactants.

-

Governments and regulatory bodies tend to move in tandem with sustainable technologies that have regard for the environment; this could provide incentives and benefits for producers of LAB.

Read Related Blog : Linear Alkyl Benzene Sulfonic Acid (LABSA) Business Plan for Production

-

LAB is generated from readily available and easily accessible raw materials, which include benzene and linear alpha-olefins.

-

Setting up production facilities in regions with supportive logistics and infrastructure facilities can help optimise supply chain operations.

-

Lab can be formulated to suit particular applications for customers, lending flexibility and the ability to cater to very diverse market demand requirements.

-

Industry Expertise and Innovation

-

LAB production technology is very well established, and there is a large knowledge and expertise base available for new entrants.

-

In the LAB sector, such continuous R&D has generated perpetual improvement in product performance and process efficiency.

-

Further opportunities for innovation lie in the development of new formulations and LAB applications, which will provide further differentiation in the market.

-

The establishment of a LAB manufacturing plant would create jobs in the manufacturing process, quality control, logistics, and administration.

-

It is clear, for instance, that a chemical industry may thus support regional development economically through the development of local businesses and infrastructures.

Read Related Books : Chemical Technology (Organic, Inorganic, Industrial), Fine Chemicals

Challenges -

-

Effective supply chain management ensures that raw materials and finished products arrive on time. Coordinating with suppliers and distributors is quite tricky, which requires some efficient logistics planning.

-

There is an increasing demand made on chemical companies to become sustainable. Some of the painful improvements demanded from companies include bettering energy efficiency, reducing wastes, and increasing corporate social responsibility—all of which, though painful, are the best way for the future.

-

In the production of LAB, there are chemical processes involved that can have an impact on the environment. In this regard, waste management, control of emissions, and prevention of pollution are necessary in order to comply with legislation and reduce the level of ecological footprint.

-

LAB is a very dangerous chemical, and its handling and storage must be done with much care. There should be robust safety measures in place for the protection of the workers and also to prevent possible environmental contamination. Proper training and implemented safety protocols may reduce these risks associated with LAB.

-

LAB production requires specialized technology and infrastructure.

-

LAB is used in the production of surfactants and has specific regulations concerning its production, use, and disposal. The requirements for compliance with local and international regulations are increasingly strict, and obtaining permits and certifications is time- and resource-consuming.

Considerations -

-

Assess the demand in these markets and identify potential customers, including major detergent manufacturers and industrial users.

-

Invest in the right technology for LAB production through the alkylation route of benzene, considering efficiency, scalability, and the cost of the technology with regard to compliance with industry standards.

-

Secure dependable sources of raw material supply for benzene and long-chain alkanes. Cost and availability shifts will affect your overall production costs.

-

Stay informed about trends in the chemical industry and consumer preferences. Adapting to changes in market demand and industry standards can help you remain competitive.

-

LAB production is skilled-labor intensive; hence, a great number of chemists, chemical engineers, and technicians are needed. Ensure access to a skilled workforce with relevant experience in the process involved and safety considerations.

-

Conduct regular and complete trainings with respect to proper handling of chemicals, safety practices, and emergency response for all employees. This is because LAB production deals with hazardous materials that might turn fatal if the people dealing with them are not properly trained.

-

Determine the number of employees required at different cadres and shift patterns. Plan needs in operation, including production, maintenance, quality, and administration.

-

Foster continuous learning and improvement among all staff. Professional development investment, along with keeping current with the industry trends, shall further upgrade workforce capabilities.

Best locations in India for opening chemical industry on Linear alkyl Benzene -

-

Mumbai of Maharashtra

-

Vadodara, Surat, Ahmedabad of Gujarat

-

Tamilnadu and Coimbatore of Chennai

-

Telangana of Hyderabad

-

Bangalore and Karnataka

-

Visakhapatnam of Andhra Pradesh

-

Jamshedpur of Jharkhand

-

Kolkata of West Bengal

Facts to consider -

-

Proximity to raw materials: Feedstocks and other input raw materials required for the production process of LAB.

-

Infrastructure: availability of dependable utilities such as water and electricity, transportation links, and logistics support.

-

Regulatory Environment: Local regulations, permit ease, and compliance requirements.

-

Operations Cost: Land, Labor, overall operation cost.

-

Market access—Allowing proximity to principal markets and prospective customers.

CONCLUSION

Reasons for establishing businesses in the chemical industry such as Linear Alkyl Benzene include strong demand in the market, proven economic viability, breakthrough potential for both innovation and sustainability, and profitable and efficient manufacturing in such an industry. The demand for surfactants currently may have the laborious and intricate supply process for LAB highly profitable and efficient if done efficiently, possibly offering strategic advantage as well. The core ingredients for success come with quality, sustainability and market insight to establish a right standing in this absolutely important industry.

For any Inquiry on Chemical Industry : Visit NPCS

See More Links:

YouTube Channel

Startup Consulting Services

Start a Business in Middle East Countries

Most Demandable Business Ideas for Startups

Business Ideas with Low, Medium & High Investment

|