The Pharmaceutical Tablet Market is booming, with no sign of letting up in the near future. Researchers involved in the ingredient production process must therefore select ingredients that will help their product stand out in an already saturated market. In 2015, nearly 15% of people worldwide used a pharmaceutical tablet; add half a billion people to that statistic and you have the 2018 estimates.

Sugar spheres are porous pellets that are typically composed of sucrose and starch. Comprising a tablet’s core, the pellets are blended with other tablet ingredients, such as active pharmaceutical ingredients (APIs). Because they are most commonly found in sustained release tablets, other excipients may also be found in the mixture. Its spherical shape is ideal due to its flow ability, particularly when being poured in bulk. Additionally, after blending the pellet with APIs and other excipients, compression of the newly-formed tablet occurs; this process is easier and more efficient with a spherical pellet.

Related Projects:- Pharmaceutical, Drugs, Fine Chemicals, Bulk Drug Intermediates

To ensure uniform application of APIs, sugar spheres particle size should be closely distributed. The international sieve series defines μm limits for particle size based on American Society for Testing and Materials (ASTM) standard sieves. A wide range of particle sizes are available on the market, which is hugely beneficial to laboratories that require a variety of sizes for different tablets.

Pellets that are friable are easily crumbled; this trait can be good in some situations, but is certainly not a desirable trait for pharmaceutical tablets. Sugar spheres are advantageous because of their low friability, which allows them to withstand the rigorous tablet coating, handling, and other production processes. Specifically, one study cited friability values of 0.6-1.7% as acceptable for withstanding these processes.

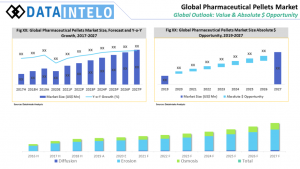

Market Overview of Pharma Sugar Pellets:

· The Global Sugar Sphere Market was valued at USD 142.4 Million in 2019 and is projected to reach USD 229.9 Million by 2027, growing at a CAGR of 6.5% from 2020 to 2027. Increased demand from the pharmaceutical industry and from emerging countries will significantly drive the growth of the market. Patient-friendly dosages also raise the demand for the Global Sugar Sphere Market. The Global Business Sugar Sphere Market provides a holistic evaluation of the market.

Related Books: - Pharmaceutical, Drugs, Proteins Technology Handbooks

· Sugar Spheres are primarily utilized as inert cores in tablets and capsules formulations, especially multiparticulate sustained-release formulations. They create the base upon that a pharmaceutical drug is coated, generally followed by release modifying polymer coating. In addition to this, multiparticulate drug delivery process is increasing as pharma companies seek to enhance clinical effectiveness. . Sugar spheres are expected to be a crucial excipient for solid medications in the coming years too with the probability of being utilized successfully as a method for new developments.

Related Videos:- Pharmaceutical, Drugs, Fine Chemicals, Bulk Drug Intermediates, Pharmaceutical Drugs, Pharma Drug Ingredients Intermediates, Pharmaceutical Bulk Drugs

· Sugar spheres are considered as key ingredients in various medications administered in the pellet form. In research studies, sugar pellets have proven their worth compared to their alternative concepts.

Read our Book Here: Handbook on Active Pharmaceutical Ingredients (API), Drugs & Pharmaceutical Products

Due to the numerous benefits of sugar spheres, new applications are continuing to emerge, including compressing coated pellets to manufacture sustained-release tablets or multiple unit tablets. Sugar spheres are included in the Food and Drug Administration (FDA) Inactive Ingredients Guide for oral tablets and tablets. They are also included in non-parenteral drugs approved in the UK and Europe.

Conclusion:

The scope of the project report by NPCS includes assessing market potential, negotiating with collaborators, investment decision making, and corporate diversification planning etc. in a much planned manner by formulating detailed manufacturing techniques. Many of the engineers, project consultant & industrial consultancy firms in India and worldwide have taken advantage from the project reports provided by NPCS. You can check all the project report on the official website of NPCS.